-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 00:57

Back to list

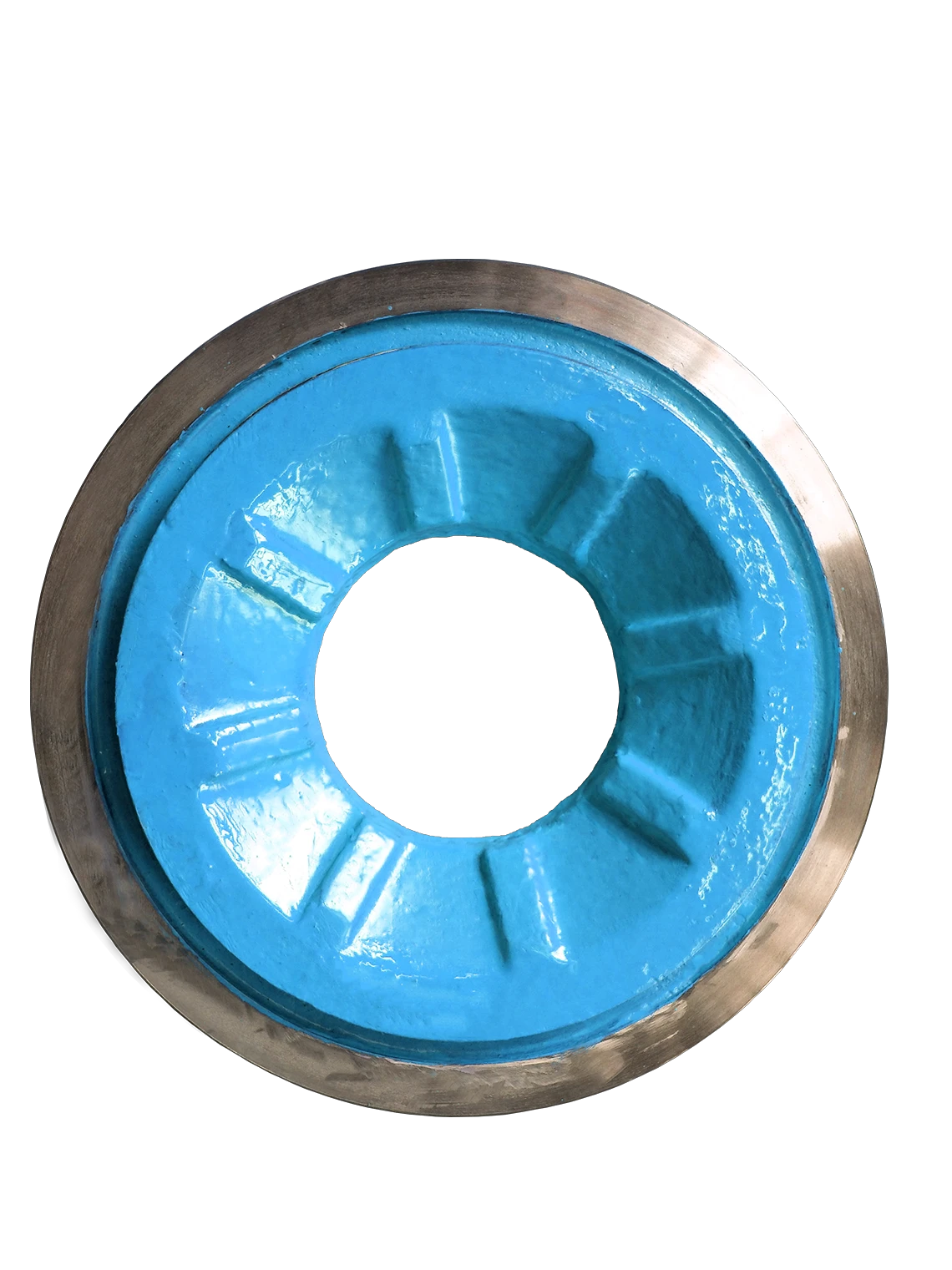

pump impeller material selection

Selecting the right material for a pump impeller is a critical decision that significantly influences the operational efficiency, lifespan, and overall performance of a pump. With many options available, this process requires careful consideration of various factors that cater to the specific needs of an application. Achieving the optimal balance between cost, durability, and performance isn't merely a choice but an intricate decision-making process drawing from both empirical and theoretical foundations.

Trustworthiness in material selection is also reinforced by understanding customized solutions for abrasive applications, such as mining or slurries handling. Materials like white cast iron or hard-faced steel coatings are recommended due to their high hardness and resistance to abrasion. Real-world experiences from mining operations validate the longevity and cost-effectiveness of these materials, leading to a reduction in operational costs and an increase in uptime. Moreover, the foresight to anticipate future operational challenges can further enhance the trustworthiness of a material choice. For instance, the trend towards more sustainable and energy-efficient pumps has led to the innovation of composite materials and engineered polymers. These materials are increasingly gaining traction due to their lightweight nature and resistance to diverse environmental factors. Their application in low-pressure or non-demanding scenarios provides a contemporary solution that aligns with modern sustainability goals. The collaboration between engineers, material scientists, and industry specialists ensures that material selection for pump impellers is not done in isolation but as an informed choice supported by a wealth of empirical data and real-world performance benchmarks. The developments in computational modeling and simulation have also augmented material development, providing accurate predictions about material behavior under specific operational conditions. This intersection of technology and science fosters informed decisions, combining trust with verified expertise. Ensuring a pump system's resilience, efficiency, and performance starts with the foundation of proper material selection. Beyond theoretical knowledge, reliance on meticulously documented case studies, long-term field tests, and professional consultancies ensures that the choices made are not only data-driven but also reflect practical wisdom. Such a holistic approach guarantees that a pump impeller's material selection will not only meet but exceed operational demands, fortifying the pump's role as a reliable workhorse across industries.

Trustworthiness in material selection is also reinforced by understanding customized solutions for abrasive applications, such as mining or slurries handling. Materials like white cast iron or hard-faced steel coatings are recommended due to their high hardness and resistance to abrasion. Real-world experiences from mining operations validate the longevity and cost-effectiveness of these materials, leading to a reduction in operational costs and an increase in uptime. Moreover, the foresight to anticipate future operational challenges can further enhance the trustworthiness of a material choice. For instance, the trend towards more sustainable and energy-efficient pumps has led to the innovation of composite materials and engineered polymers. These materials are increasingly gaining traction due to their lightweight nature and resistance to diverse environmental factors. Their application in low-pressure or non-demanding scenarios provides a contemporary solution that aligns with modern sustainability goals. The collaboration between engineers, material scientists, and industry specialists ensures that material selection for pump impellers is not done in isolation but as an informed choice supported by a wealth of empirical data and real-world performance benchmarks. The developments in computational modeling and simulation have also augmented material development, providing accurate predictions about material behavior under specific operational conditions. This intersection of technology and science fosters informed decisions, combining trust with verified expertise. Ensuring a pump system's resilience, efficiency, and performance starts with the foundation of proper material selection. Beyond theoretical knowledge, reliance on meticulously documented case studies, long-term field tests, and professional consultancies ensures that the choices made are not only data-driven but also reflect practical wisdom. Such a holistic approach guarantees that a pump impeller's material selection will not only meet but exceed operational demands, fortifying the pump's role as a reliable workhorse across industries.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024