-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 06:39

Back to list

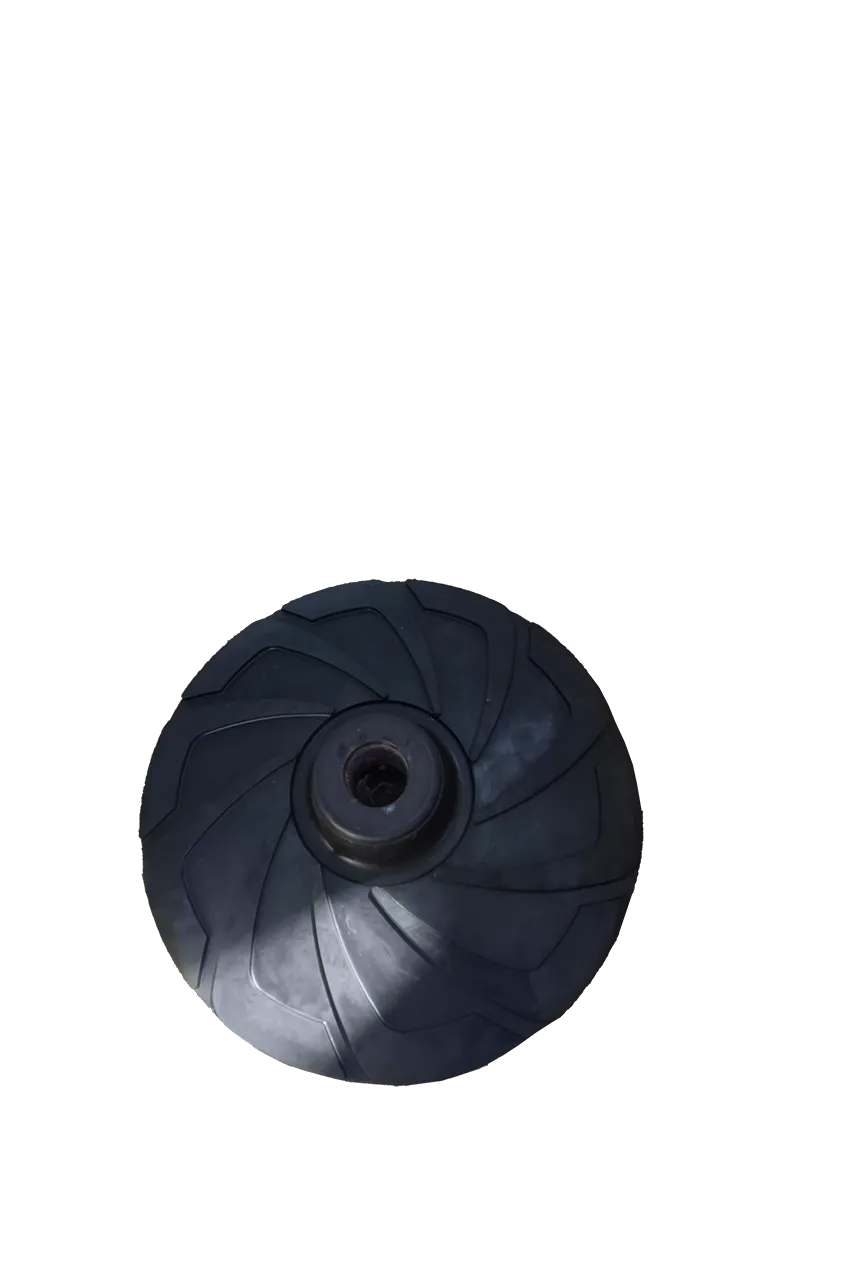

pump impeller material

Selecting the right pump impeller material is crucial for ensuring the longevity, efficiency, and performance of pumps across various industrial applications. The choice of material directly impacts the pump's ability to handle different fluids, resist wear and tear, and operate under varying environmental conditions. Herein lies an expertise-driven guide to navigating the complex landscape of pump impeller materials, addressing all facets from material properties to real-world applications, thereby establishing trust and authority in the decision-making process.

Composite and polymer-based impellers are increasingly gaining traction in applications demanding lightweight and cost-effective solutions. Materials such as reinforced plastics or elastomers offer excellent corrosion resistance and flexibility in manufacturing, allowing engineers to design complex geometries suited for specific fluid dynamics. These materials are particularly advantageous in corrosive environments where metallic materials may suffer rapid degradation. In the realm of cutting-edge applications, impellers made from advanced ceramics are making waves due to their unrivaled hardness and thermal stability. Ceramic impellers are tenacious against both chemical and mechanical wear, making them an ideal choice for high-speed applications and extreme temperature conditions. However, the brittleness of ceramics requires careful consideration during installation and operation to prevent fracture and undue material stress. Decision-makers are advised to balance initial cost implications with long-term operational benefits when selecting impeller materials. While materials like titanium and ceramics may present a higher upfront cost, their durability and resistance to extreme conditions can result in significant cost savings over the pump's operational life span. Engaging with material experts and industry veterans can provide invaluable insights tailored to specific applications, fostering confidence and trust in material selection decisions. Consulting with experienced engineers and material scientists is paramount in making informed decisions about impeller materials, ensuring that selections align with both the technical demands of the application and the economic constraints of the project. Utilizing computational fluid dynamics (CFD) and finite element analysis (FEA) can further optimize material performance, allowing for simulations of real-world conditions and potential failure modes, effectively positioning stakeholders to anticipate and mitigate risks. In conclusion, the intricacies of selecting the optimal pump impeller material require a confluence of experience, expertise, and authority. Manufacturers and operators who invest in understanding these dynamics can unlock enhanced reliability, performance, and safety in their pump operations, ultimately achieving cost efficiencies and maintaining competitive advantage in their respective markets.

Composite and polymer-based impellers are increasingly gaining traction in applications demanding lightweight and cost-effective solutions. Materials such as reinforced plastics or elastomers offer excellent corrosion resistance and flexibility in manufacturing, allowing engineers to design complex geometries suited for specific fluid dynamics. These materials are particularly advantageous in corrosive environments where metallic materials may suffer rapid degradation. In the realm of cutting-edge applications, impellers made from advanced ceramics are making waves due to their unrivaled hardness and thermal stability. Ceramic impellers are tenacious against both chemical and mechanical wear, making them an ideal choice for high-speed applications and extreme temperature conditions. However, the brittleness of ceramics requires careful consideration during installation and operation to prevent fracture and undue material stress. Decision-makers are advised to balance initial cost implications with long-term operational benefits when selecting impeller materials. While materials like titanium and ceramics may present a higher upfront cost, their durability and resistance to extreme conditions can result in significant cost savings over the pump's operational life span. Engaging with material experts and industry veterans can provide invaluable insights tailored to specific applications, fostering confidence and trust in material selection decisions. Consulting with experienced engineers and material scientists is paramount in making informed decisions about impeller materials, ensuring that selections align with both the technical demands of the application and the economic constraints of the project. Utilizing computational fluid dynamics (CFD) and finite element analysis (FEA) can further optimize material performance, allowing for simulations of real-world conditions and potential failure modes, effectively positioning stakeholders to anticipate and mitigate risks. In conclusion, the intricacies of selecting the optimal pump impeller material require a confluence of experience, expertise, and authority. Manufacturers and operators who invest in understanding these dynamics can unlock enhanced reliability, performance, and safety in their pump operations, ultimately achieving cost efficiencies and maintaining competitive advantage in their respective markets.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024