-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 13, 2025 18:52

Back to list

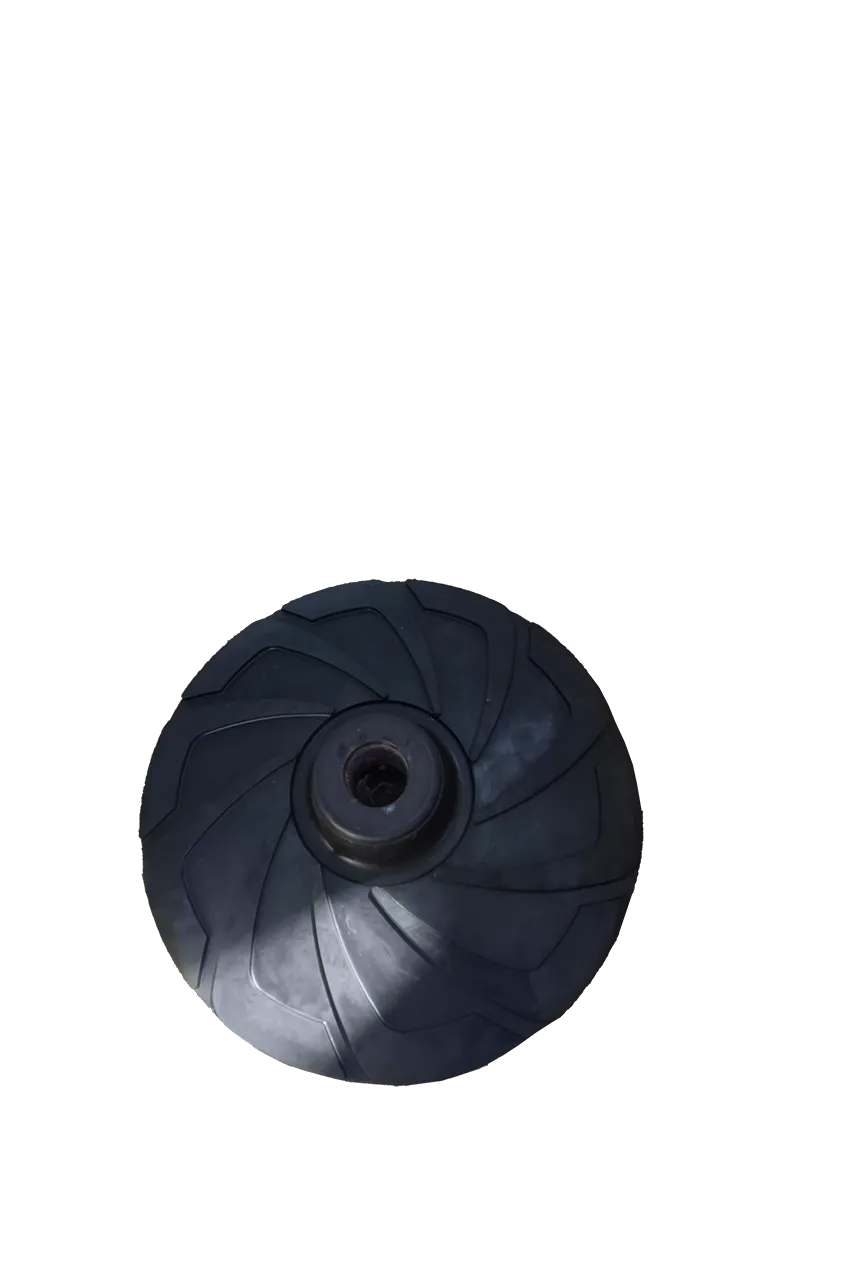

Horizontal Slurry Pumps MM3/2C-AHR

Operating at the heart of fluid transportation systems, pump impellers play a critical role in numerous industrial applications. For those sourcing high-quality pump impellers, understanding what sets apart a superior manufacturing process is crucial. Here's an immersive exploration of what makes a reputable pump impeller factory stand out, coupled with insights that exemplify Experience, Expertise, Authoritativeness, and Trustworthiness.

Safety and Training Protocols In the realm of manufacturing, safety is paramount. Authoritative factories adhere to rigorous safety protocols, providing their workforce with comprehensive training programs that not only prevent accidents but also improve operational efficiencies. A well-trained team is pivotal in maintaining quality control and upholding safety standards, particularly when handling sophisticated machinery and hazardous materials. Industry Authority and Customer Trust An authoritative pump impeller factory commands respect and trust within the industry. By maintaining a portfolio of certifications, such as ISO 9001 for quality management systems, and achieving endorsements from global engineering bodies, these manufacturers assure clients of their adherence to the highest quality benchmarks. Customer trust is further bolstered by testimonials and case studies, showcasing successful partnerships and proven results across diverse sectors such as oil and gas, municipal water services, and chemical processing plants. In Practice Partnering for Success Choosing the right pump impeller factory is more than a mere supplier decision; it's a partnership that can drive innovation and efficiency within an organization. The best factories open their doors, offering client tours and transparent insights into their operations. This transparency fosters an environment of collaboration and trust, essential for tailoring solutions that meet complex technical requirements and delivery timelines. Experience is best summed up through the diligent execution of projects, often reflected in the lengthy tenure of key clients who repeatedly entrust a factory with their critical components. It’s this blend of time-honored craftsmanship and innovation that defines the modern pump impeller factory—a partner as reliable as the products it manufactures. Conclusively, the quest for premium pump impellers is made easier with the guidance of a factory that exemplifies experience, expertise, authoritativeness, and trustworthiness. By understanding the integral processes and values that drive leading manufacturers, businesses can make informed decisions that enhance operational efficiency and fortify their competitive standing in the market.

Safety and Training Protocols In the realm of manufacturing, safety is paramount. Authoritative factories adhere to rigorous safety protocols, providing their workforce with comprehensive training programs that not only prevent accidents but also improve operational efficiencies. A well-trained team is pivotal in maintaining quality control and upholding safety standards, particularly when handling sophisticated machinery and hazardous materials. Industry Authority and Customer Trust An authoritative pump impeller factory commands respect and trust within the industry. By maintaining a portfolio of certifications, such as ISO 9001 for quality management systems, and achieving endorsements from global engineering bodies, these manufacturers assure clients of their adherence to the highest quality benchmarks. Customer trust is further bolstered by testimonials and case studies, showcasing successful partnerships and proven results across diverse sectors such as oil and gas, municipal water services, and chemical processing plants. In Practice Partnering for Success Choosing the right pump impeller factory is more than a mere supplier decision; it's a partnership that can drive innovation and efficiency within an organization. The best factories open their doors, offering client tours and transparent insights into their operations. This transparency fosters an environment of collaboration and trust, essential for tailoring solutions that meet complex technical requirements and delivery timelines. Experience is best summed up through the diligent execution of projects, often reflected in the lengthy tenure of key clients who repeatedly entrust a factory with their critical components. It’s this blend of time-honored craftsmanship and innovation that defines the modern pump impeller factory—a partner as reliable as the products it manufactures. Conclusively, the quest for premium pump impellers is made easier with the guidance of a factory that exemplifies experience, expertise, authoritativeness, and trustworthiness. By understanding the integral processes and values that drive leading manufacturers, businesses can make informed decisions that enhance operational efficiency and fortify their competitive standing in the market.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024