-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 05, 2025 03:42

Back to list

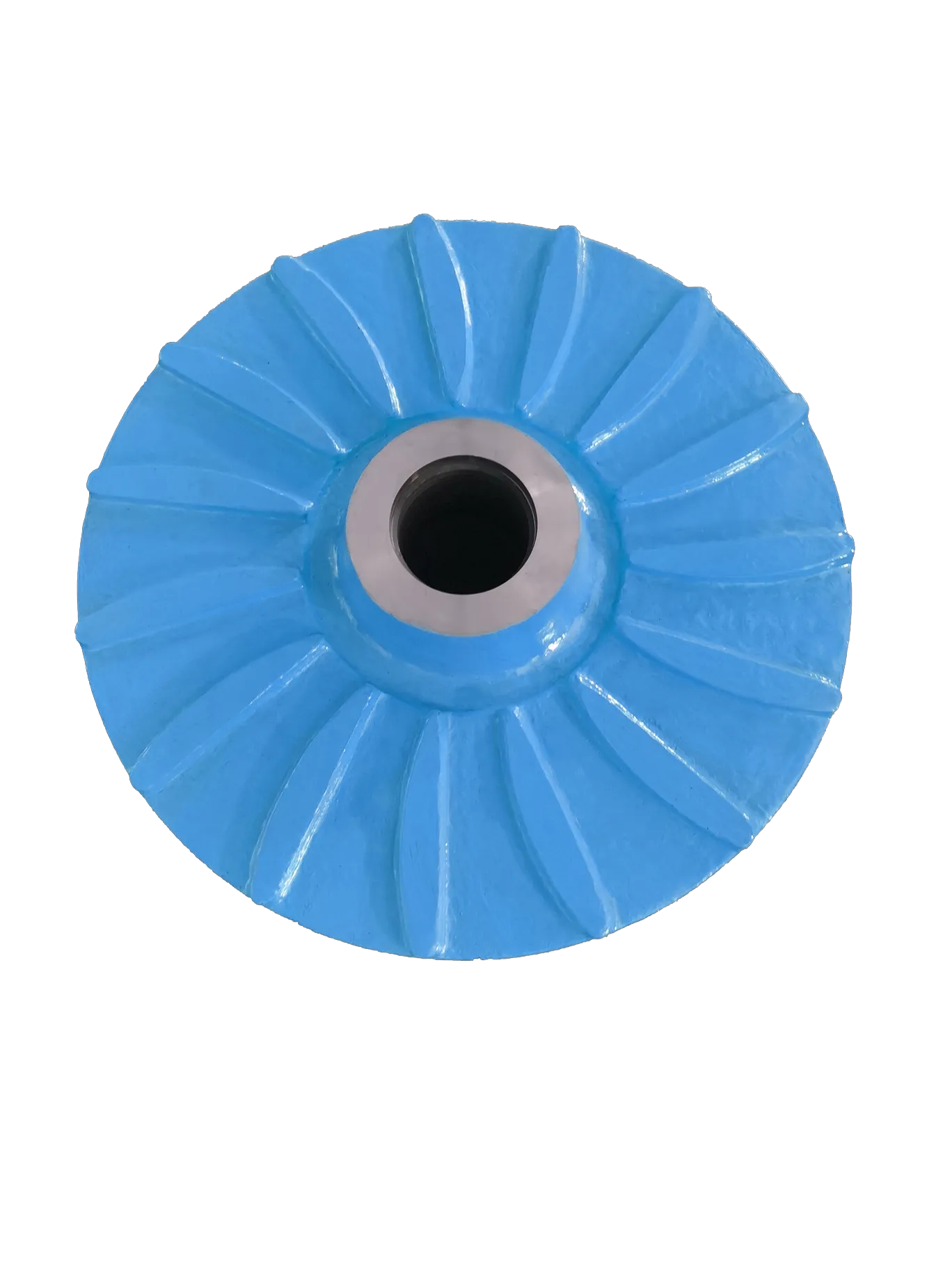

pump casing wear ring

Pump casing wear rings play a pivotal role in maintaining the operational efficiency and longevity of centrifugal pumps. These components are situated between the impeller and the pump casing, serving as a critical interface that directly influences the hydraulic performance and mechanical stability of the pump. Understanding the intricacies and significance of wear rings is essential for anyone involved in pump maintenance, operations, or design.

The expertise needed to handle pump casing wear rings spans various aspects of engineering, including materials science, fluid dynamics, and mechanical integrity analysis. Professionals in this field employ sophisticated computational tools and empirical data to analyze wear patterns, predict service life, and optimize ring design for specific applications. This approach ensures that the pump remains reliable and effective throughout its operational lifespan. Authoritativeness in the domain of wear rings is often derived from extensive research and field experience. Industry leaders and seasoned engineers contribute valuable insights into design improvements and innovative materials, influencing best practices across the sector. These insights are shared through technical papers, industry seminars, and collaborative projects that enhance collective knowledge about wear ring technology. Trustworthiness stems from a commitment to quality and performance standards. Reputable manufacturers conduct rigorous testing of their wear ring materials and designs to validate their performance under various operational scenarios. Such testing often includes endurance trials, chemical exposure tests, and performance simulations that replicate real-life operational conditions. By maintaining transparent and high-quality manufacturing processes, these companies build trust with their clients, ensuring that their wear rings meet the demanding requirements of industrial applications. In conclusion, pump casing wear rings are indispensable components that significantly affect the operational efficiency and reliability of centrifugal pumps. Their effective selection, design, and maintenance require a thorough understanding of material properties, hydraulic principles, and mechanical dynamics. As the industry continues to evolve, ongoing research and technological advancements promise to enhance the durability and performance of wear rings even further, cementing their role as a vital element in pump technology. Whether you are involved in engineering, maintenance, or procurement, a deep appreciation of wear ring function and design will undoubtedly aid in optimizing pump performance and extending the life of pumping equipment.

The expertise needed to handle pump casing wear rings spans various aspects of engineering, including materials science, fluid dynamics, and mechanical integrity analysis. Professionals in this field employ sophisticated computational tools and empirical data to analyze wear patterns, predict service life, and optimize ring design for specific applications. This approach ensures that the pump remains reliable and effective throughout its operational lifespan. Authoritativeness in the domain of wear rings is often derived from extensive research and field experience. Industry leaders and seasoned engineers contribute valuable insights into design improvements and innovative materials, influencing best practices across the sector. These insights are shared through technical papers, industry seminars, and collaborative projects that enhance collective knowledge about wear ring technology. Trustworthiness stems from a commitment to quality and performance standards. Reputable manufacturers conduct rigorous testing of their wear ring materials and designs to validate their performance under various operational scenarios. Such testing often includes endurance trials, chemical exposure tests, and performance simulations that replicate real-life operational conditions. By maintaining transparent and high-quality manufacturing processes, these companies build trust with their clients, ensuring that their wear rings meet the demanding requirements of industrial applications. In conclusion, pump casing wear rings are indispensable components that significantly affect the operational efficiency and reliability of centrifugal pumps. Their effective selection, design, and maintenance require a thorough understanding of material properties, hydraulic principles, and mechanical dynamics. As the industry continues to evolve, ongoing research and technological advancements promise to enhance the durability and performance of wear rings even further, cementing their role as a vital element in pump technology. Whether you are involved in engineering, maintenance, or procurement, a deep appreciation of wear ring function and design will undoubtedly aid in optimizing pump performance and extending the life of pumping equipment.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024