-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

pump casing wear ring

Understanding Pump Casing Wear Rings Importance and Maintenance

Pump systems are critical components in various industrial applications, providing essential functions in fluid transfer, processing, and management. Among the many components that ensure the efficient operation of a pump, the wear ring plays a fundamental role. Specifically, the pump casing wear ring is designed to enhance performance and longevity while minimizing maintenance costs. This article explores the significance of wear rings, their function, common issues, and best practices for maintenance.

What Are Pump Casing Wear Rings?

Wear rings are typically circular components made from durable materials, designed to minimize the gap between the impeller and the pump casing. They serve as a buffer that controls the recirculation of fluid, which can cause inefficiencies and wear over time. The primary purpose of wear rings is to maintain proper clearance, ensuring optimal hydraulic performance while minimizing leakage.

Functions of Wear Rings

1. Fluid Efficiency By reducing leakage and recirculation, wear rings help maintain the pump's efficiency. This is crucial for applications where even minor losses can result in significant performance degradation.

2. Wear Prevention As pumps operate, components experience wear due to constant friction and abrasive particles present in the fluid. Wear rings act as sacrificial elements—they absorb wear, protecting the casing and impeller.

3. Enhanced Lifespan By minimizing the wear on critical components, wear rings contribute to the extended lifespan of the pump. This leads to lower replacement costs and reduced downtime, which is particularly beneficial in industrial settings.

4. Vibration Reduction Proper clearances maintained by wear rings can help reduce vibrations, leading to a smoother operation. Excessive vibration can lead to premature wear and potential failure of other pump components.

Common Issues with Wear Rings

Despite their importance, wear rings can suffer from several issues, primarily due to inappropriate material choices, installation errors, or neglect in maintenance. Some common problems include

1. Excessive Wear Over time, wear rings can degrade, leading to increased gaps that reduce efficiency. If left unchecked, excessive wear can result in greater fluid leakage and operational failure.

pump casing wear ring

2. Misalignment Incorrect installation may lead to misalignment, causing uneven wear on the rings. Regular inspections can help identify such issues early.

3. Material Degradation The choice of material for wear rings is critical. Some materials are more susceptible to abrasion or corrosion, depending on the fluid being pumped. Using the right material is essential for preventing failure.

4. Contamination The presence of abrasive particles in the fluid can accelerate wear on the rings. Regular filtering and maintenance of the pumped fluid are necessary to prevent contamination-related wear.

Best Practices for Wear Ring Maintenance

To maximize the lifespan and efficiency of pump casing wear rings, operators should adopt the following best practices

1. Regular Inspections Scheduling routine checks can help identify signs of wear early. Operators should monitor clearances and look for signs of misalignment or unusual vibrations.

2. Proper Material Selection Choose wear ring materials that are tailored to the specific pumping environment. Consider factors such as fluid composition, temperature, and pressure when selecting materials.

3. Fluid Quality Control Implement filtration systems to reduce contamination in the pumped fluid. Maintaining fluid quality not only protects wear rings but also contributes to overall pump health.

4. Training and Education Ensure that pump operators and maintenance staff are well-trained in the importance of wear rings and the specific maintenance procedures required.

Conclusion

Pump casing wear rings are vital components that significantly affect the efficiency and longevity of pump systems. Understanding their role and maintaining them effectively can lead to improved performance and reduced operational costs. By recognizing common issues and implementing best practices for their upkeep, industries can optimize their pumping operations and ensure that their systems remain robust and reliable for years to come. Effective management of wear rings ultimately leads to a more efficient fluid handling process, supporting the operational goals of numerous industrial applications.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

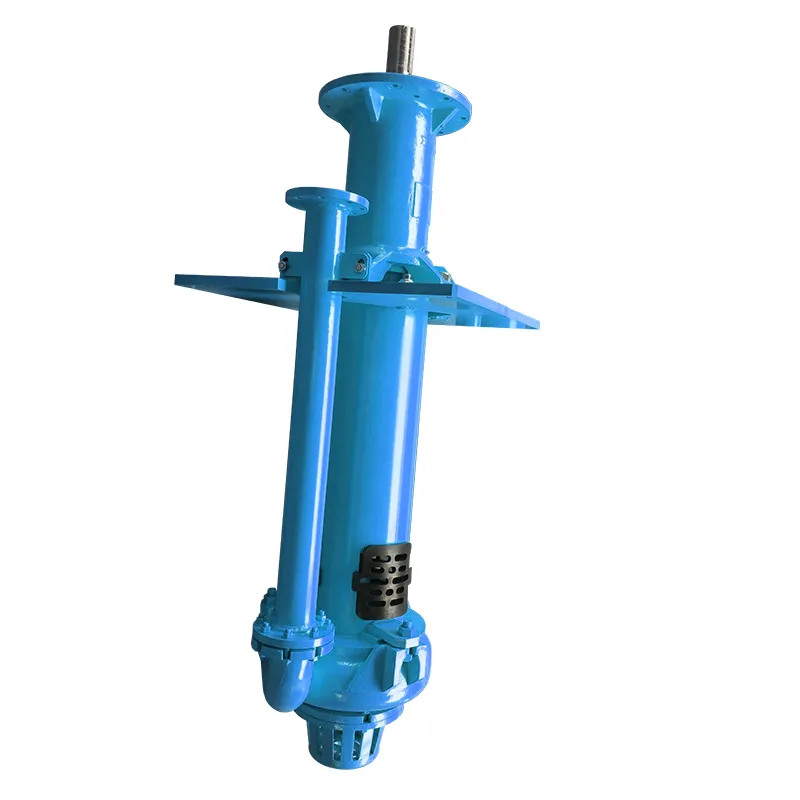

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024