-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 10, 2025 10:58

Back to list

pump assembly procedure

The art of mastering the pump assembly procedure is a journey into the intricacies of mechanical engineering, where precision, expertise, and trusted techniques come together to create a seamlessly functioning system. This detailed exploration reveals insights drawn from years of hands-on experience and high-level expertise, guiding both novice operators and seasoned professionals through this essential industrial task.

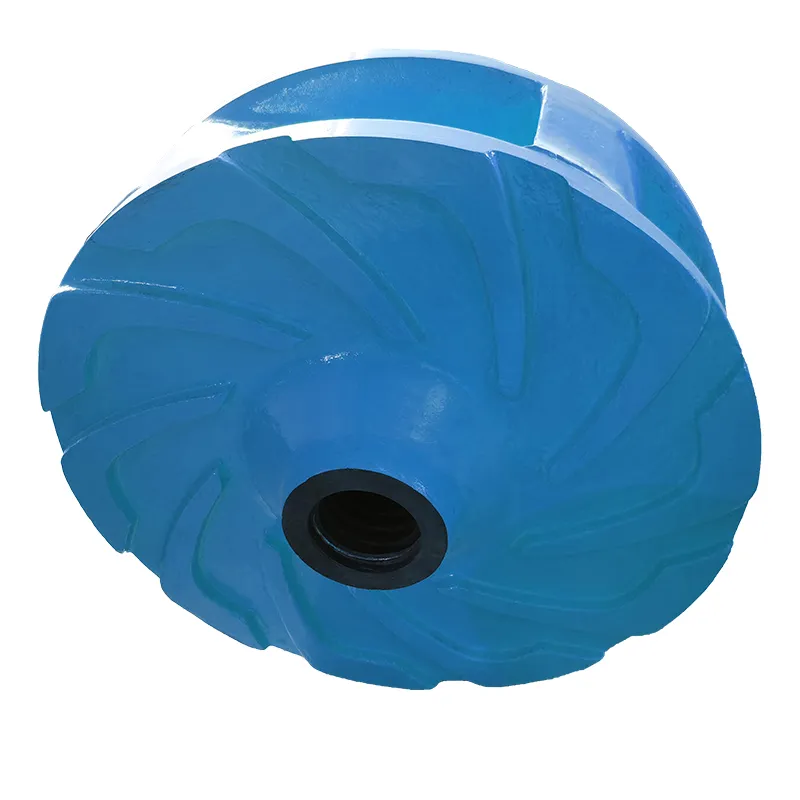

Aligning components involves a balance of precision and methodology. Components such as the impeller and volute must be fitted according to exact specifications to ensure optimal performance. Any deviation from these specifications can lead to inefficiencies or machinery breakdowns. Professionals often rely on torque wrenches to ensure bolts are tightened to the correct tension, preventing either over-tightening or insufficient securing, both of which can be detrimental. After assemblage, the final phases of the pump assembly procedure involve rigorous testing to verify that the assembly has been successful and that no issues such as leaks or mechanical failures are present. Hydrostatic testing may be employed to ensure that seals are intact and that the pump can operate under expected pressure conditions. This testing phase reflects a commitment to professional excellence and a guarantee of trust in the equipment’s future performance. Documentation, often an overlooked step, is an integral part of an authoritative assembly procedure. Recording each step, from initial inspections to final testing outcomes, provides a historical log that can be invaluable for future maintenance or troubleshooting tasks. This documentation lends transparency and accountability, reassuring clients and stakeholders of the professional and thorough approach applied to each assembly project. Finally, post-assembly maintenance and monitoring are essential practices that extend the life of a pump and affirm a professional’s expertise. Regular checks for vibration, pressure, and temperature can preemptively identify potential issues, maintaining the pump's integrity and operational efficiency. In sum, a pump assembly procedure that focuses on preparation, precision, and continuous learning embodies the qualities of experience and expertise. By adopting a methodical and conscientious approach, professionals not only enhance the reliability and performance of their machinery but also establish themselves as authoritative figures in their field, trusted by their peers and clients alike.

Aligning components involves a balance of precision and methodology. Components such as the impeller and volute must be fitted according to exact specifications to ensure optimal performance. Any deviation from these specifications can lead to inefficiencies or machinery breakdowns. Professionals often rely on torque wrenches to ensure bolts are tightened to the correct tension, preventing either over-tightening or insufficient securing, both of which can be detrimental. After assemblage, the final phases of the pump assembly procedure involve rigorous testing to verify that the assembly has been successful and that no issues such as leaks or mechanical failures are present. Hydrostatic testing may be employed to ensure that seals are intact and that the pump can operate under expected pressure conditions. This testing phase reflects a commitment to professional excellence and a guarantee of trust in the equipment’s future performance. Documentation, often an overlooked step, is an integral part of an authoritative assembly procedure. Recording each step, from initial inspections to final testing outcomes, provides a historical log that can be invaluable for future maintenance or troubleshooting tasks. This documentation lends transparency and accountability, reassuring clients and stakeholders of the professional and thorough approach applied to each assembly project. Finally, post-assembly maintenance and monitoring are essential practices that extend the life of a pump and affirm a professional’s expertise. Regular checks for vibration, pressure, and temperature can preemptively identify potential issues, maintaining the pump's integrity and operational efficiency. In sum, a pump assembly procedure that focuses on preparation, precision, and continuous learning embodies the qualities of experience and expertise. By adopting a methodical and conscientious approach, professionals not only enhance the reliability and performance of their machinery but also establish themselves as authoritative figures in their field, trusted by their peers and clients alike.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024