-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 19, 2025 05:26

Back to list

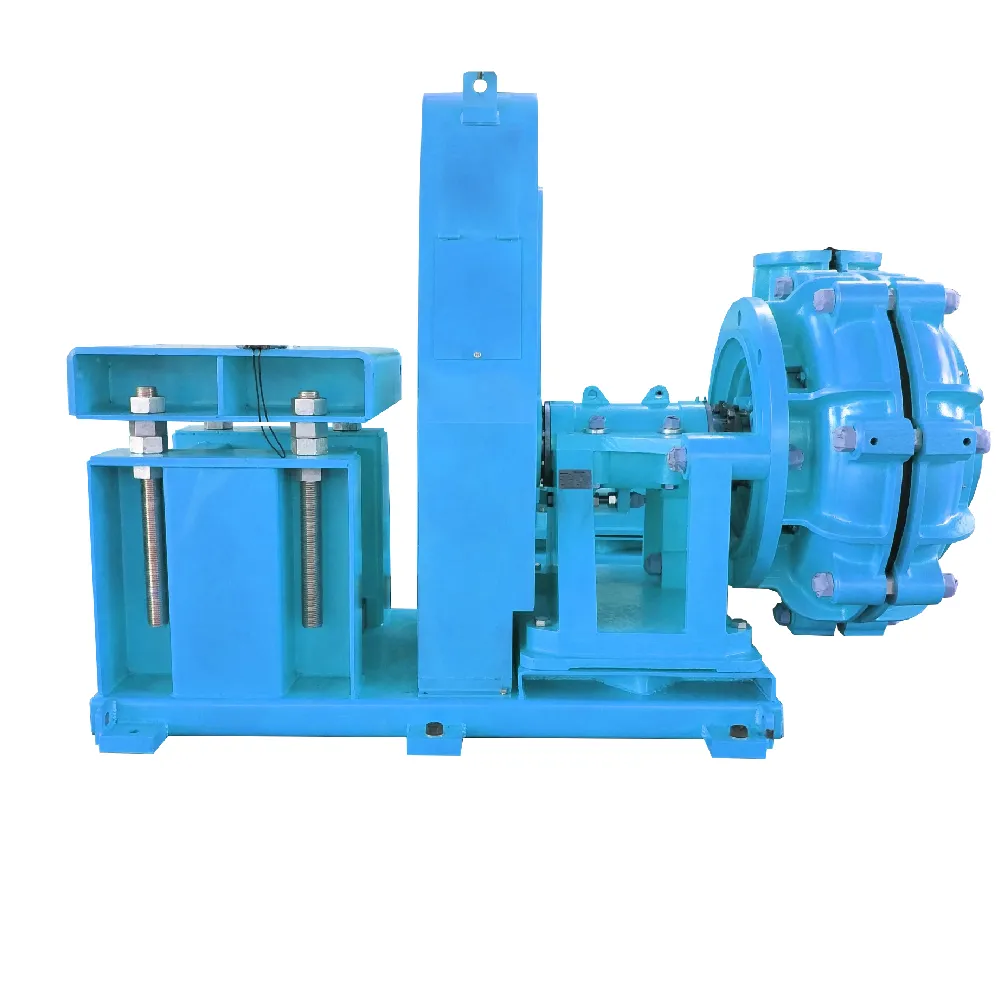

pompa slurry

Understanding the intricacies of slurry pumps is crucial for industries that handle fluids mixed with solid materials, which include the mining, construction, and chemical sectors. A slurry pump, often referred to as a sludge pump, is designed to handle the abrasive nature of such mixtures while maintaining efficiency and longevity.

An often-underestimated factor is the training of personnel responsible for operating and maintaining slurry pumps. Proper training ensures operators understand how to adjust pump settings to optimize performance and recognize early signs of potential issues. Empowering employees with this knowledge fosters an environment of proactive maintenance, leading to increased trustworthiness and cost effectiveness. Selecting a supplier with a solid reputation and a track record of reliability is equally paramount. Suppliers that offer comprehensive post-purchase support, including technical advice, readily available parts, and responsive service, invariably contribute to minimizing downtime and enhancing production efficiency. The environmental impact of slurry pumps is also an increasingly significant factor. With industries worldwide moving towards sustainability, ensuring that slurry pumps comply with environmental standards while maintaining their effectiveness is crucial. Innovations in energy efficiency, reduction of noise pollution, and longer-lasting materials are leading the way in making slurry pumps not only a functional part of industry but also a responsible choice in the quest for greener operations. In summary, the successful integration and operation of slurry pumps into industrial processes demand more than just a basic understanding of their mechanical functions. Expertise in material choice, the adaptability of design to application needs, and strategic maintenance all contribute to long-term success. These factors ensure that slurry pumps remain a backbone of fluid transfer systems across demanding industries.

An often-underestimated factor is the training of personnel responsible for operating and maintaining slurry pumps. Proper training ensures operators understand how to adjust pump settings to optimize performance and recognize early signs of potential issues. Empowering employees with this knowledge fosters an environment of proactive maintenance, leading to increased trustworthiness and cost effectiveness. Selecting a supplier with a solid reputation and a track record of reliability is equally paramount. Suppliers that offer comprehensive post-purchase support, including technical advice, readily available parts, and responsive service, invariably contribute to minimizing downtime and enhancing production efficiency. The environmental impact of slurry pumps is also an increasingly significant factor. With industries worldwide moving towards sustainability, ensuring that slurry pumps comply with environmental standards while maintaining their effectiveness is crucial. Innovations in energy efficiency, reduction of noise pollution, and longer-lasting materials are leading the way in making slurry pumps not only a functional part of industry but also a responsible choice in the quest for greener operations. In summary, the successful integration and operation of slurry pumps into industrial processes demand more than just a basic understanding of their mechanical functions. Expertise in material choice, the adaptability of design to application needs, and strategic maintenance all contribute to long-term success. These factors ensure that slurry pumps remain a backbone of fluid transfer systems across demanding industries.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024