-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 12, 2025 01:15

Back to list

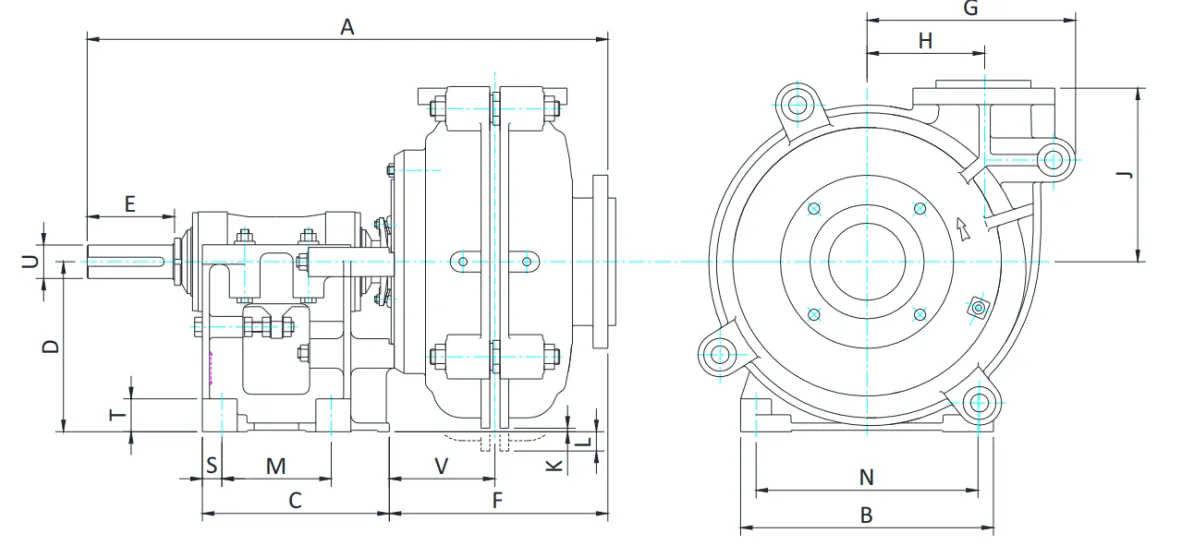

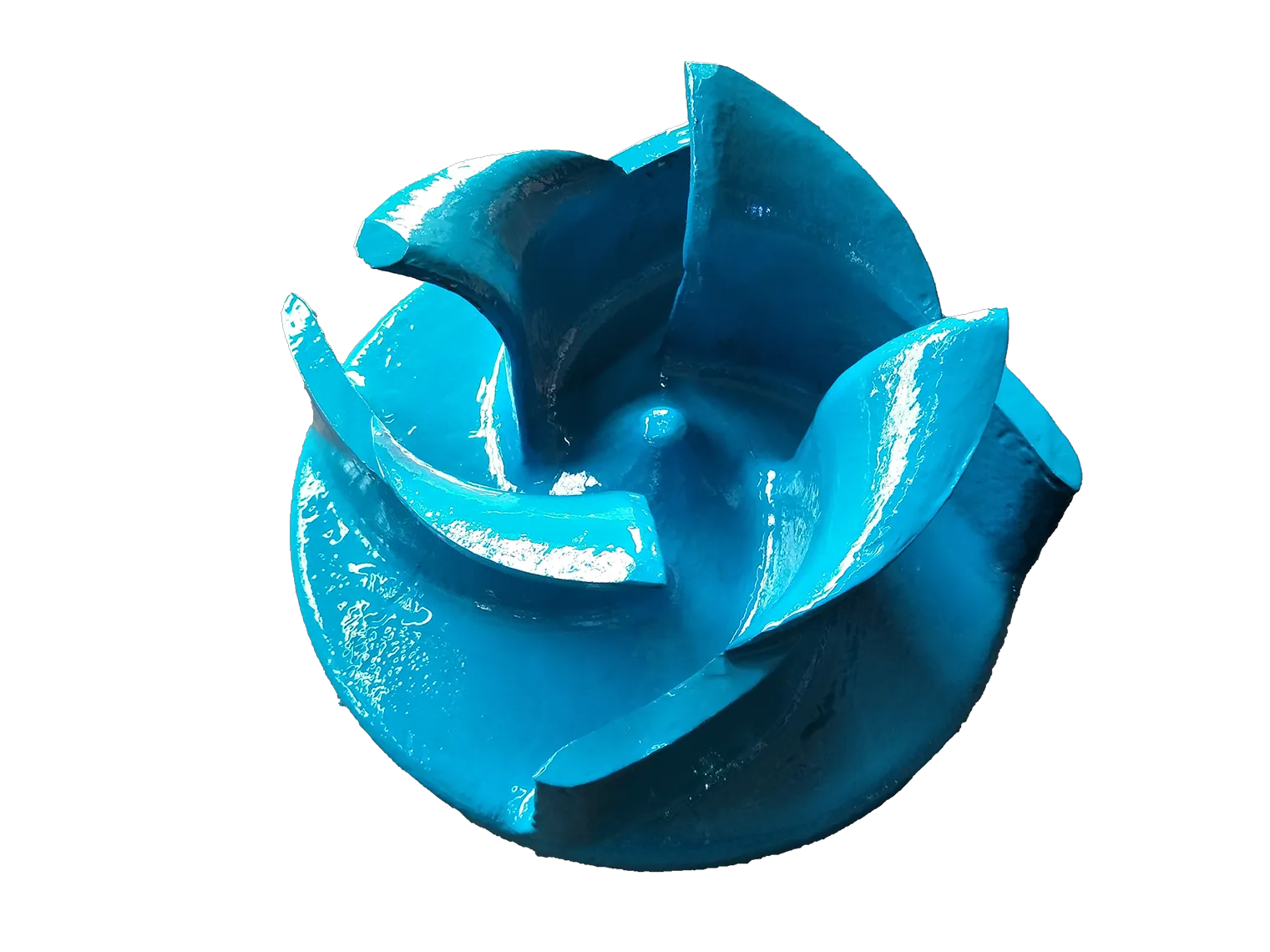

open impeller submersible pump

An open impeller submersible pump is a cutting-edge innovation in the realm of fluid management. Born out of the need for agility and efficiency, especially in challenging environments where solid-laden fluids often present a formidable challenge, this pump type provides compelling advantages. Its unique design features a less obstructed passageway, allowing for easier movement of both fluids and solids. This feature, while simple, offers significant gains in performance and reliability, particularly in sectors such as construction, mining, and wastewater management.

From an engineering perspective, open impeller submersible pumps are a textbook example of ingenuity meeting functionality. Their structural simplicity translates to fewer components at risk of wear and tear. Additionally, these pumps often feature sealed motors and components, ensuring they can withstand corrosive environments, thus prolonging their operational life. Such longevity, combined with their reduced risk of clogging, makes them an exemplary choice for industries looking to optimize their fluid management processes without compromising on performance or reliability. Moreover, when considering environmental impact, open impeller submersible pumps contribute positively by reducing energy consumption. Their design optimizes fluid movement, which in turn requires less energy to operate efficiently. Whether in managing floodwaters or aiding in mining operations, these pumps deliver power without excessive energy drain, aligning operational efficiency with sustainable practices. As the industrial landscape evolves, the need for reliable, efficient, and durable pumping solutions continues to grow. Open impeller submersible pumps provide a pathway towards achieving superior fluid control with minimal environmental impact. For engineers and operators, choosing this type of pump translates to embracing innovation without sacrificing capability, achieving operational excellence with every deployment. Their proven record in demanding scenarios makes them a staple in modern engineering practices, combining expert design with unmatched practicality.

From an engineering perspective, open impeller submersible pumps are a textbook example of ingenuity meeting functionality. Their structural simplicity translates to fewer components at risk of wear and tear. Additionally, these pumps often feature sealed motors and components, ensuring they can withstand corrosive environments, thus prolonging their operational life. Such longevity, combined with their reduced risk of clogging, makes them an exemplary choice for industries looking to optimize their fluid management processes without compromising on performance or reliability. Moreover, when considering environmental impact, open impeller submersible pumps contribute positively by reducing energy consumption. Their design optimizes fluid movement, which in turn requires less energy to operate efficiently. Whether in managing floodwaters or aiding in mining operations, these pumps deliver power without excessive energy drain, aligning operational efficiency with sustainable practices. As the industrial landscape evolves, the need for reliable, efficient, and durable pumping solutions continues to grow. Open impeller submersible pumps provide a pathway towards achieving superior fluid control with minimal environmental impact. For engineers and operators, choosing this type of pump translates to embracing innovation without sacrificing capability, achieving operational excellence with every deployment. Their proven record in demanding scenarios makes them a staple in modern engineering practices, combining expert design with unmatched practicality.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024