-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

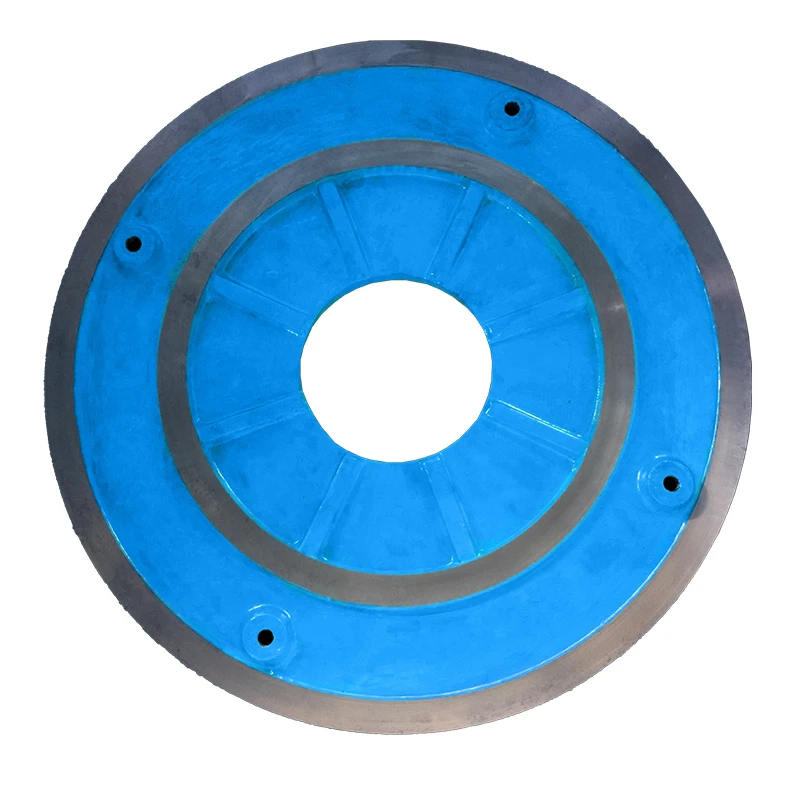

open impeller submersible pump

Understanding Open Impeller Submersible Pumps

Submersible pumps have gained prominence in various industrial and agricultural applications due to their efficiency and versatility. Among the different designs available, open impeller submersible pumps stand out for their unique operational principles and advantages. This article explores the characteristics, mechanisms, applications, and benefits of open impeller submersible pumps.

What is an Open Impeller Submersible Pump?

An open impeller submersible pump consists of a rotating element with vanes that have no back shroud, allowing a greater flow of liquid. The absence of a back shroud facilitates a higher flow capacity and reduces the possibility of clogging—making it ideal for transporting liquids that may contain solids or other debris. This design allows the impeller to impart kinetic energy to the liquid, propelling it upward or outward as needed for various applications.

Working Mechanism

The key to the functionality of open impeller submersible pumps lies in their unique design. When the pump is submerged in a fluid, the motor—usually housed within the same unit—drives the impeller to rotate at high speeds. As the impeller spins, it creates a low-pressure area at the eye (the center) of the impeller, drawing fluid into it. The rotational energy is converted into kinetic energy, which accelerates the liquid outward through the vanes. This movement generates high pressure at the pump outlet, allowing the fluid to be discharged through piping systems.

The open design of the impeller promotes superior flow rates and is particularly effective in handling mixed or contaminated liquids. Since there is no shroud restricting the blade's movement, the pump can efficiently handle solids suspended within the liquid. This capability is particularly useful in wastewater management and agricultural applications where debris and solids can be prevalent.

Applications

open impeller submersible pump

Open impeller submersible pumps are widely utilized across various sectors

. Some of the prominent applications include1. Wastewater Treatment These pumps are ideal for transporting sewage and wastewater in municipal treatment facilities due to their resistance to clogging. 2. Agricultural Irrigation Farmers often use open impeller pumps for irrigating crops, especially in areas where water sources may contain debris or silt. 3. Construction Sites They are effective in dewatering excavations and construction sites, where muddy or debris-laden water is common. 4. Mining Operations These pumps can handle slurries and are commonly used in mining applications where water mixed with soil and minerals must be moved efficiently.

5. Flood Control Open impeller submersible pumps play a crucial role in controlling floods by rapidly removing excess water from areas prone to inundation.

Benefits

The benefits of open impeller submersible pumps are manifold

- High Efficiency The design allows for greater flow rates and reduced energy consumption compared to other pump types. - Versatility Capable of handling various types of liquids, including those containing solids and debris. - Ease of Maintenance Many open impeller pumps feature simple designs that make maintenance and repair straightforward. - Cost-Effectiveness Their efficiency and durability reduce operational costs, making them a favored choice for long-term applications.

Conclusion

Open impeller submersible pumps represent a critical technology within the pumping industry. Their unique design, robust performance, and adaptability to various situations make them essential tools in sectors ranging from agriculture to construction and wastewater management. As industries continue to evolve, the demand for effective and reliable pumping solutions will undoubtedly grow, underscoring the importance of open impeller submersible pumps in modern infrastructure.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024