-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

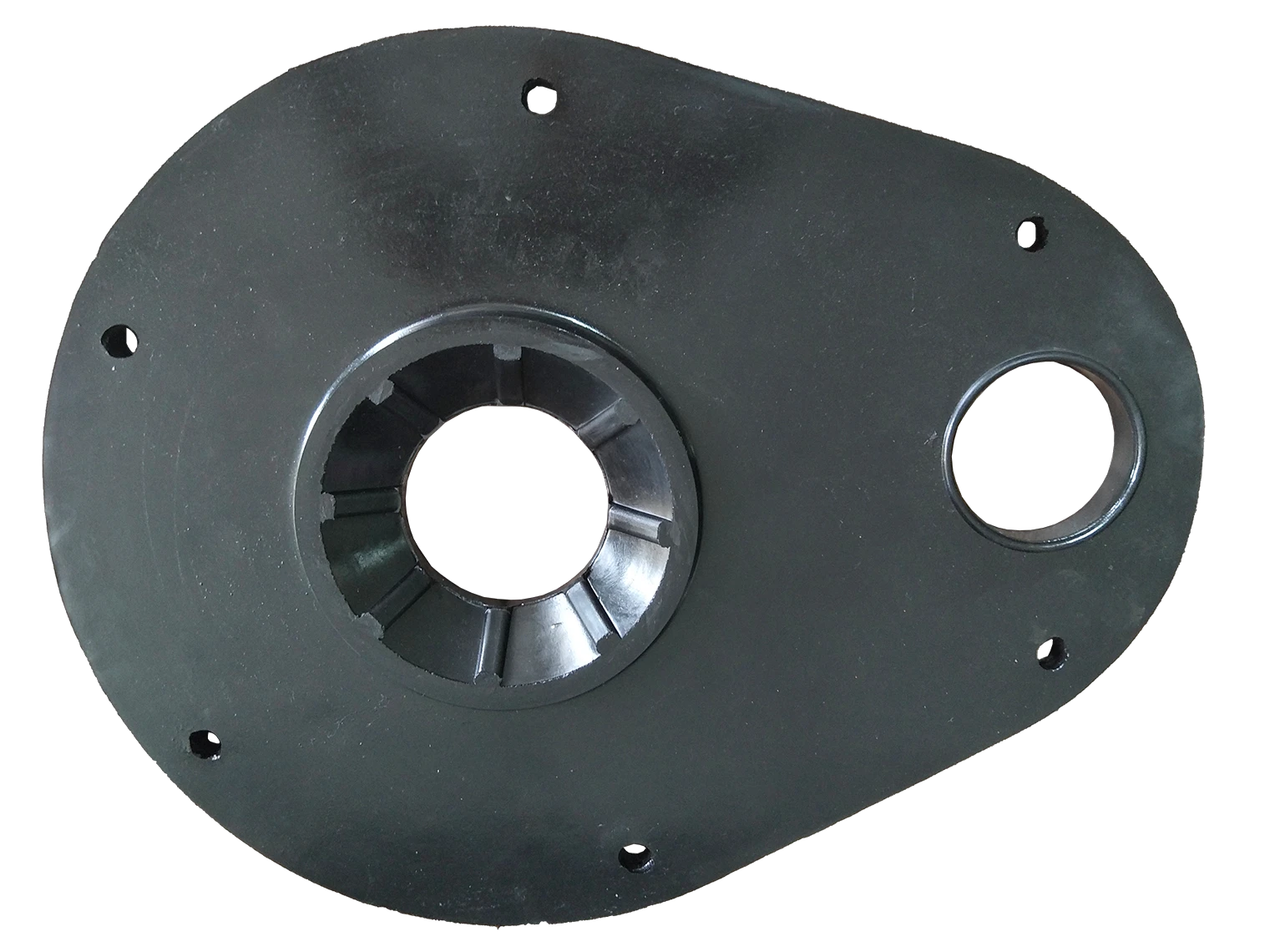

open face impeller

Understanding Open Face Impellers Design and Applications

Open face impellers are crucial components in various fluid dynamics systems, particularly in pumps and mixers, where efficient fluid movement is essential. These impellers, characterized by their absence of a closed cover or shroud, provide unique advantages and functionalities that make them a preferred choice in many industrial applications.

Design and Structure

The open face impeller features blades that extend outward from a central hub, allowing fluids to flow freely into and out of the impeller. This design enables the generation of strong vortices, enhancing the mixing and pumping capabilities of the device. Because there is no shroud, these impellers can handle fluids with varying viscosities and are less prone to clogging when working with particulates or larger solid materials.

Open face impellers typically consist of several blades that can be angled to optimize flow direction and efficiency. The number of blades and their shape (such as curved or straight) can be modified depending on the specific application, which allows engineers to customize the impeller design to meet the operational demands of a system.

Advantages of Open Face Impellers

One of the primary advantages of open face impellers is their ability to manage solid-laden fluids without significant pressure build-up. In industries such as wastewater treatment, mining, and food processing, where fluids often contain particulates, the open design reduces the risk of clogging. This is particularly vital in applications involving slurries, where the presence of solids could severely hinder the performance of conventional closed impellers.

Additionally, the open face design allows for high flow rates and the handling of lower specific gravities. This makes them suitable for low viscosity fluids, such as those found in chemical processes and mixing operations. By promoting effective fluid movement, open face impellers contribute to improved mixing and homogenization, critical for achieving desired chemical reactions or product consistency.

open face impeller

Applications

Open face impellers find applications across various industries due to their versatility. In the wastewater industry, they are often employed in aeration tanks and mixing basins, where the need for efficient oxygen transfer and solid suspension is paramount. Similarly, in the food and beverage industry, these impellers are used in processes where blending and uniform particle distribution are critical for product quality.

In the chemical industry, open face impellers facilitate the mixing of viscous liquids and slurries, ensuring consistent product properties. The ability to handle solid particles without clogging also makes them ideal for applications involving polymer solutions, where solid content can vary.

Limitations

Despite their advantages, open face impellers come with some limitations. They typically offer lower hydraulic efficiency compared to closed impellers, particularly in applications requiring high pressure. This trade-off between efficiency and the ability to handle solids needs to be carefully considered during the design phase.

Additionally, the open design can expose the impeller blades to wear and erosion from particulates, leading to the need for more frequent maintenance or replacement. Hence, selecting the appropriate materials and coatings becomes essential in prolonging the lifespan of these components.

Conclusion

Open face impellers play a vital role in a variety of industrial processes by providing efficient fluid handling capabilities, particularly when dealing with solid-laden or viscous fluids. Their unique design allows for customized applications across many sectors, from wastewater treatment to chemical processing. While they do present some challenges, the benefits they offer in specific conditions often outweigh their limitations, making them an integral part of modern fluid management systems. Understanding the functionality and best applications of open face impellers is crucial for engineers and operators who aim to optimize their processes and enhance performance in fluid dynamics applications.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024