-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 15:46

Back to list

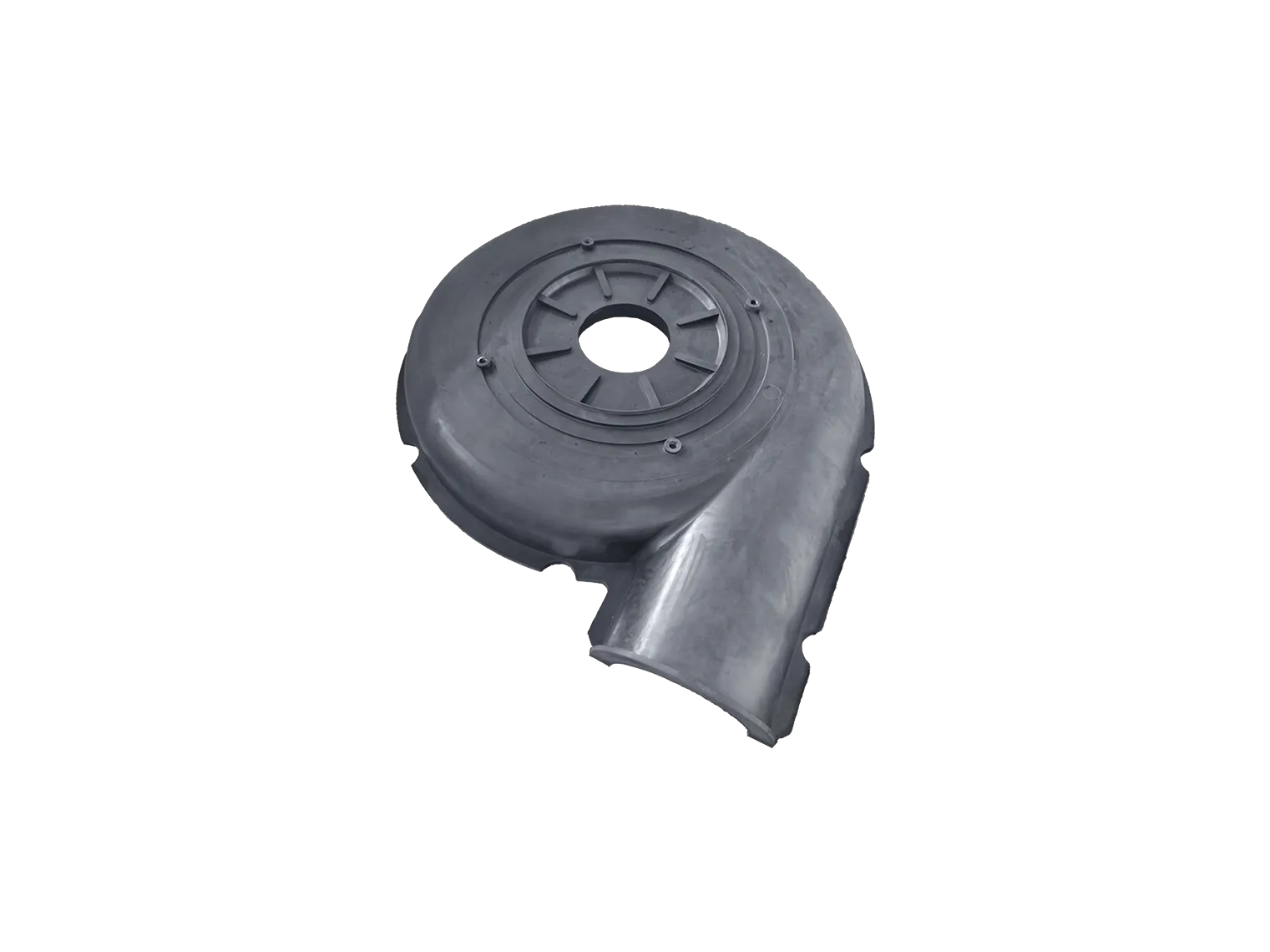

material of pump impeller

When delving into the world of pump impellers, a well-considered choice of material is paramount. This decision significantly impacts the performance, longevity, and efficiency of a pump, especially under varying operational conditions. Having spent years in the engineering field, my insights reflect both practical experience and an academic understanding of the intricacies involved in selecting the right material for pump impellers.

It's crucial to recognize the evolving landscape of material science. Innovations are continually advancing the properties of impeller materials. Emerging composite materials are being developed to enhance performance metrics, such as wear resistance and thermal stability, while also reducing the environmental impact of production. Expertise in this field extends beyond mere material selection. It involves understanding the interaction between the chosen impeller material and the pump's operating environments. Real-world applications have repeatedly demonstrated that overlooking environmental factors can lead to premature failure, inefficiency, and costly downtime. A comprehensive assessment should include the fluid's temperature, potential for chemical reaction, and particulate nature. Moreover, collaborations with manufacturers can provide insights into cutting-edge materials and technologies. These partnerships often yield custom solutions tailored to specific operational demands, ensuring optimal performance and reliability. As a seasoned professional in this field, advocating for such expert collaborations can spearhead innovations, leading to more robust and efficient pumping solutions. In conclusion, the material of a pump impeller is a core determinant of a pump’s performance and reliability. Selecting the appropriate material requires a blend of real-world experience, in-depth technical knowledge, and awareness of emerging trends. Trustworthiness in this choice stems from a holistic understanding of both the demands of the application and the capabilities of available materials. Thus, fostering seamless integration across the pump's lifecycle, from design through to operation, is essential for achieving excellence in fluid handling systems.

It's crucial to recognize the evolving landscape of material science. Innovations are continually advancing the properties of impeller materials. Emerging composite materials are being developed to enhance performance metrics, such as wear resistance and thermal stability, while also reducing the environmental impact of production. Expertise in this field extends beyond mere material selection. It involves understanding the interaction between the chosen impeller material and the pump's operating environments. Real-world applications have repeatedly demonstrated that overlooking environmental factors can lead to premature failure, inefficiency, and costly downtime. A comprehensive assessment should include the fluid's temperature, potential for chemical reaction, and particulate nature. Moreover, collaborations with manufacturers can provide insights into cutting-edge materials and technologies. These partnerships often yield custom solutions tailored to specific operational demands, ensuring optimal performance and reliability. As a seasoned professional in this field, advocating for such expert collaborations can spearhead innovations, leading to more robust and efficient pumping solutions. In conclusion, the material of a pump impeller is a core determinant of a pump’s performance and reliability. Selecting the appropriate material requires a blend of real-world experience, in-depth technical knowledge, and awareness of emerging trends. Trustworthiness in this choice stems from a holistic understanding of both the demands of the application and the capabilities of available materials. Thus, fostering seamless integration across the pump's lifecycle, from design through to operation, is essential for achieving excellence in fluid handling systems.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024