-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 16, 2025 15:12

Back to list

manufacturers of slurry pumps

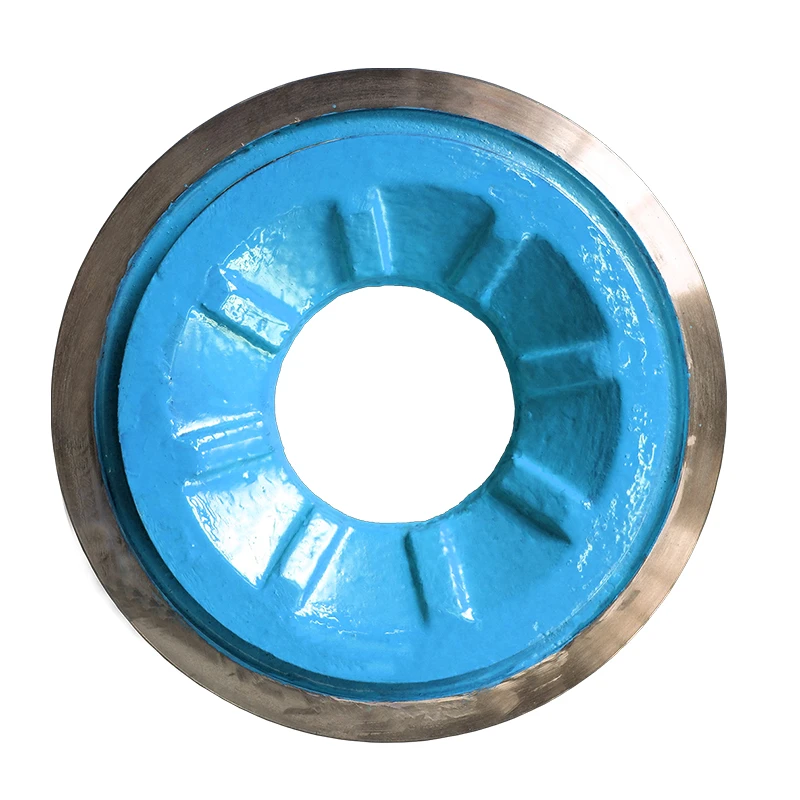

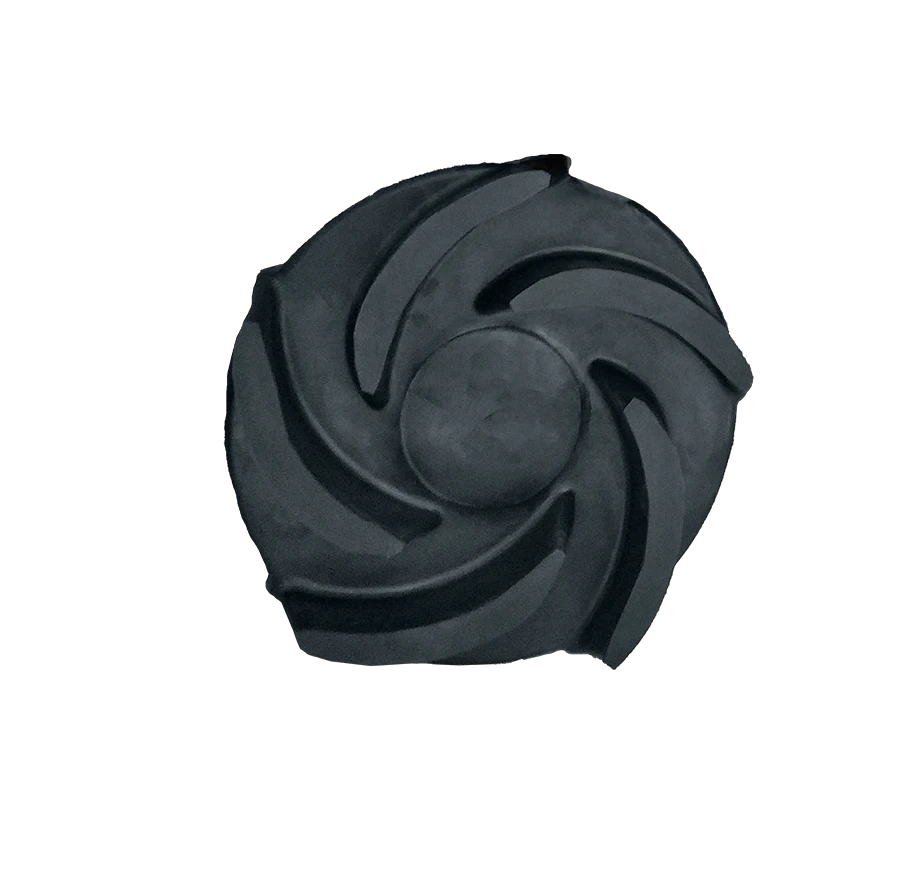

In the world of industrial applications, slurry pumps stand as a cornerstone for efficiently managing fluids with suspended solids. Manufacturers of slurry pumps play a crucial role in sectors ranging from mining to wastewater management. The expertise and precise engineering involved in manufacturing high-quality slurry pumps cannot be overstated, as it directly impacts operational efficiency and equipment longevity.

Building trust within the market is paramount. Slurry pump manufacturers achieve this by maintaining transparent communication with clients. They provide detailed documentation, including performance metrics and maintenance schedules, which help clients make informed decisions and reliably anticipate the pump’s operational lifecycle. Transparent warranties and robust after-sales services further solidify the trust between the manufacturer and the end-user. In the realm of digital presence, manufacturers enhance their trustworthiness by establishing a strong online profile. Educational content, such as case studies, technical blogs, and detailed product pages, serves as a resource for industry professionals seeking information about slurry pump solutions. By leveraging search engine optimization techniques, manufacturers can ensure this content is easily accessible, positioning themselves as thought leaders within the industry. Understanding the competitive landscape is another critical aspect for manufacturers. They must continuously analyze market trends, customer needs, and technological advancements to remain at the forefront. Engaging in industry conferences and collaborating with research institutions can help manufacturers maintain a competitive edge and drive innovation. Manufacturers of slurry pumps who have mastered these elements—expertise, authority, trust—are those that not only meet but exceed industry standards. Their contributions to sectors reliant on slurry transportation impact the efficiency and safety of operations on a global scale. As the demand for resource extraction and waste management grows, so does the responsibility and importance of these manufacturers in advancing industrial capabilities with dependable, high-performance slurry pumps.

Building trust within the market is paramount. Slurry pump manufacturers achieve this by maintaining transparent communication with clients. They provide detailed documentation, including performance metrics and maintenance schedules, which help clients make informed decisions and reliably anticipate the pump’s operational lifecycle. Transparent warranties and robust after-sales services further solidify the trust between the manufacturer and the end-user. In the realm of digital presence, manufacturers enhance their trustworthiness by establishing a strong online profile. Educational content, such as case studies, technical blogs, and detailed product pages, serves as a resource for industry professionals seeking information about slurry pump solutions. By leveraging search engine optimization techniques, manufacturers can ensure this content is easily accessible, positioning themselves as thought leaders within the industry. Understanding the competitive landscape is another critical aspect for manufacturers. They must continuously analyze market trends, customer needs, and technological advancements to remain at the forefront. Engaging in industry conferences and collaborating with research institutions can help manufacturers maintain a competitive edge and drive innovation. Manufacturers of slurry pumps who have mastered these elements—expertise, authority, trust—are those that not only meet but exceed industry standards. Their contributions to sectors reliant on slurry transportation impact the efficiency and safety of operations on a global scale. As the demand for resource extraction and waste management grows, so does the responsibility and importance of these manufacturers in advancing industrial capabilities with dependable, high-performance slurry pumps.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024