-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 19, 2025 03:36

Back to list

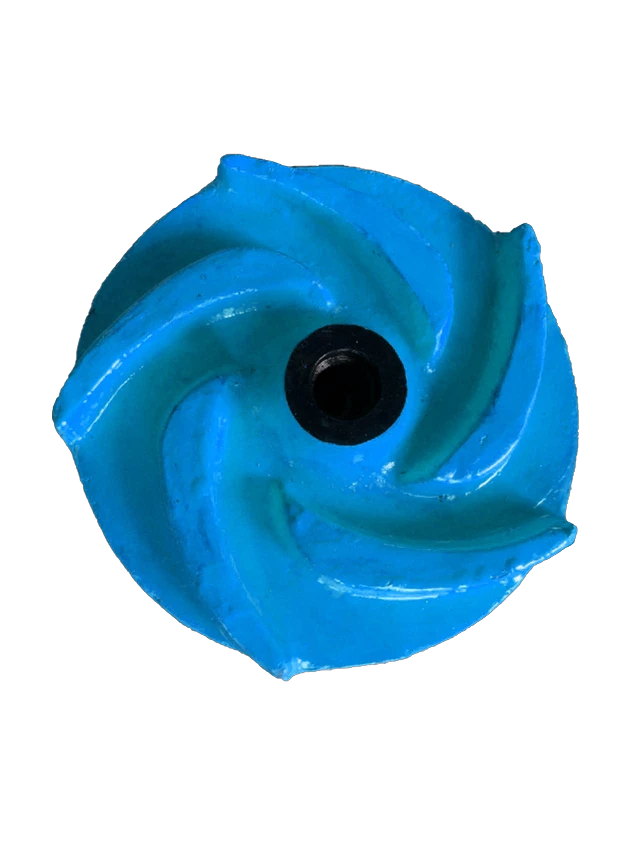

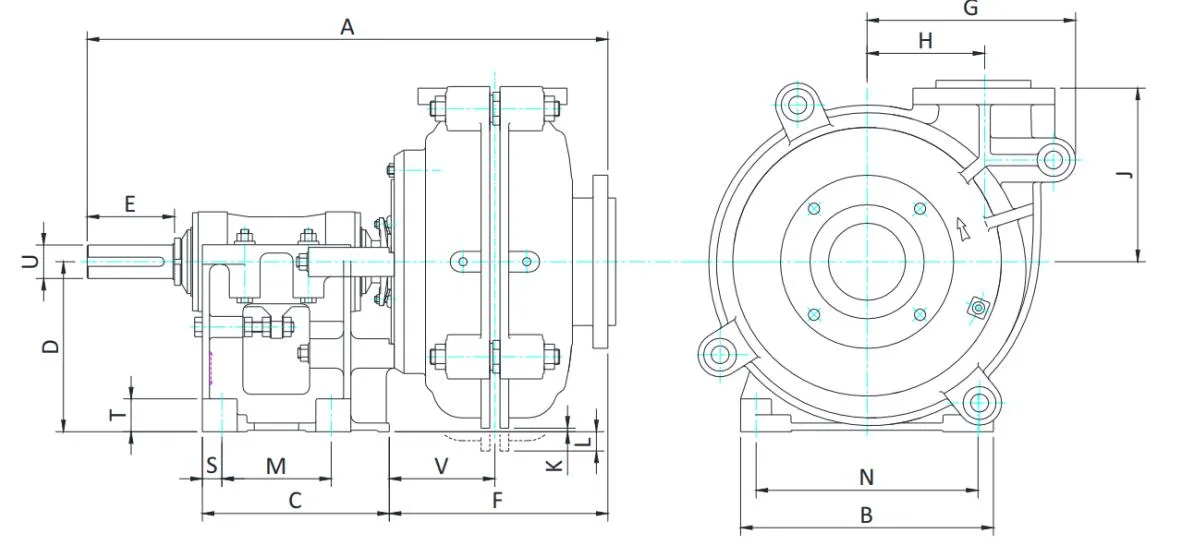

lime slurry pump

Lime slurry pumps play a crucial role in a variety of industries, including mining, power generation, and wastewater treatment. These pumps are specifically designed to handle highly abrasive and corrosive lime slurry mixtures, making them indispensable for operations that require reliable and efficient slurry management solutions.

A trusted lime slurry pump manufacturer provides more than just high-quality equipment—they also offer comprehensive support services, including installation guidance, performance monitoring, and tailored maintenance plans. Trustworthiness in this niche is built through consistent delivery of pumps that not only meet but exceed industry standards, accompanied by exemplary post-sale support. This partnership approach ensures that businesses can rely on their equipment in the long haul, fostering confidence in operational capabilities. Furthermore, innovation in the design of lime slurry pumps has led to the development of more energy-efficient models. These new designs leverage advanced materials and engineering to minimize energy consumption and enhance performance. As companies worldwide strive to reduce their environmental footprint, investing in energy-efficient lime slurry pumps aligns well with these sustainability goals. It's an investment not just in machinery, but in a greener and more efficient future. Real-world case studies illustrate the dramatic impacts a well-chosen and maintained lime slurry pump can have. One such instance involves a wastewater treatment facility that recalibrated its processes after integrating an advanced lime slurry pump system, resulting in improved processing times and significant cost reductions. Similarly, a mining operation was able to significantly boost its yield and reduce equipment downtime by selecting a high-capacity pump optimized for its specific slurry conditions. The authoritative adherence to industrial best practices, backed by hands-on experience and cutting-edge innovation, underscores the pivotal role of lime slurry pumps across essential sectors. With advances in technology and materials science continuously enhancing pump capabilities, the outlook for industries relying on these vital components remains promising. Whether you're an engineer in the field or part of a procurement team, prioritizing informed decision-making and vendor reliability is key to harnessing the full potential of lime slurry pump systems.

A trusted lime slurry pump manufacturer provides more than just high-quality equipment—they also offer comprehensive support services, including installation guidance, performance monitoring, and tailored maintenance plans. Trustworthiness in this niche is built through consistent delivery of pumps that not only meet but exceed industry standards, accompanied by exemplary post-sale support. This partnership approach ensures that businesses can rely on their equipment in the long haul, fostering confidence in operational capabilities. Furthermore, innovation in the design of lime slurry pumps has led to the development of more energy-efficient models. These new designs leverage advanced materials and engineering to minimize energy consumption and enhance performance. As companies worldwide strive to reduce their environmental footprint, investing in energy-efficient lime slurry pumps aligns well with these sustainability goals. It's an investment not just in machinery, but in a greener and more efficient future. Real-world case studies illustrate the dramatic impacts a well-chosen and maintained lime slurry pump can have. One such instance involves a wastewater treatment facility that recalibrated its processes after integrating an advanced lime slurry pump system, resulting in improved processing times and significant cost reductions. Similarly, a mining operation was able to significantly boost its yield and reduce equipment downtime by selecting a high-capacity pump optimized for its specific slurry conditions. The authoritative adherence to industrial best practices, backed by hands-on experience and cutting-edge innovation, underscores the pivotal role of lime slurry pumps across essential sectors. With advances in technology and materials science continuously enhancing pump capabilities, the outlook for industries relying on these vital components remains promising. Whether you're an engineer in the field or part of a procurement team, prioritizing informed decision-making and vendor reliability is key to harnessing the full potential of lime slurry pump systems.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024