-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 30, 2025 01:38

Back to list

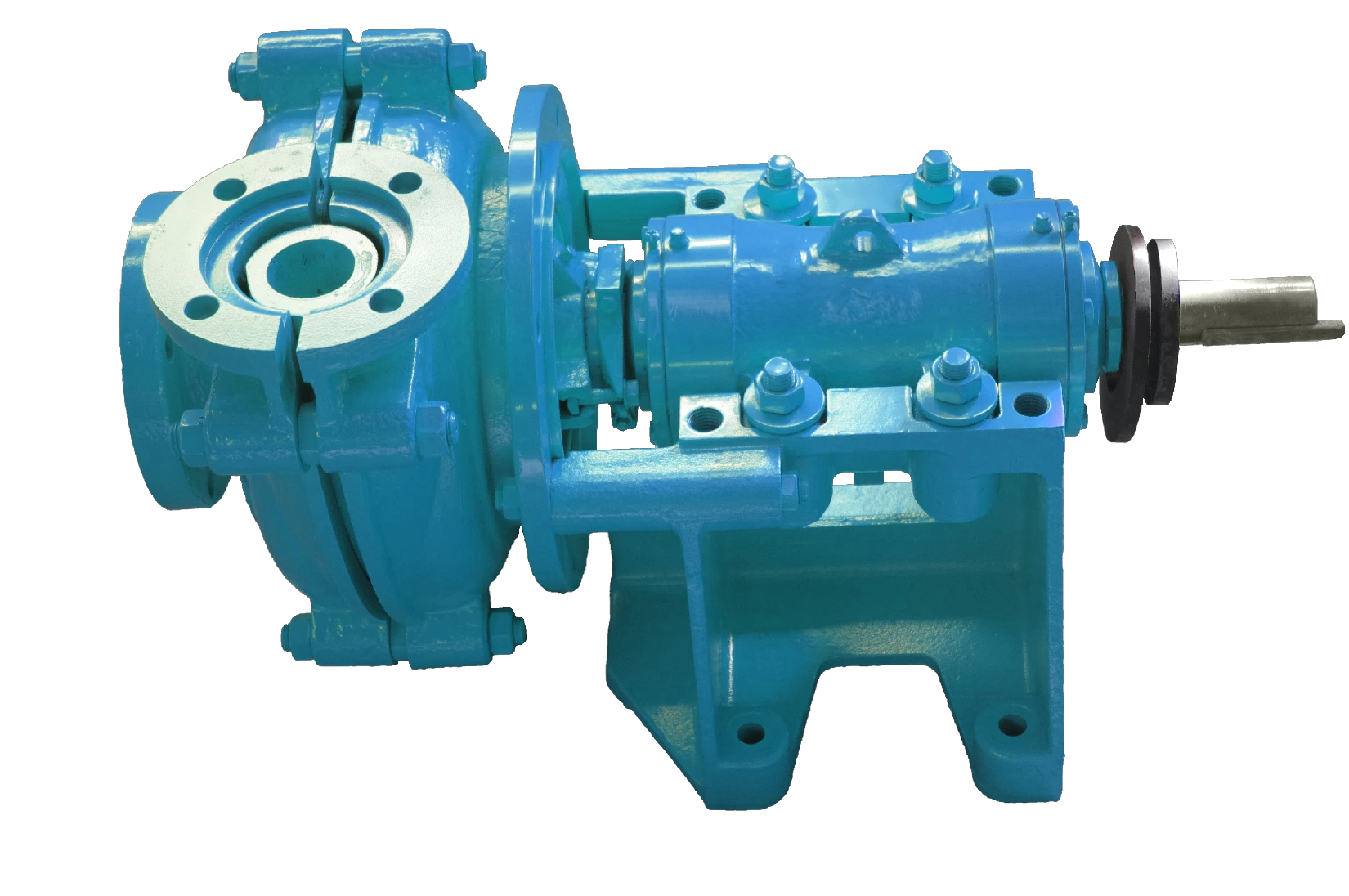

inline centrifugal pump

Inline centrifugal pumps have garnered substantial attention in various industries due to their compact design and efficient performance. These pumps have become essential components in systems requiring fluid transfer, circulation, and pressure boosting. As their adoption increases, understanding their operational intricacies becomes paramount for ensuring optimal performance and achieving desired outcomes.

One of the key aspects contributing to the user experience with inline centrifugal pumps is their user-friendly interface. Modern inline centrifugal pumps incorporate advanced technology features such as digital controllers and remote monitoring systems. These features offer real-time data analysis, enabling operators to make informed decisions and adjustments to optimize performance. The ability to monitor and control pump operations remotely not only enhances efficiency but also allows for proactive maintenance, thus preventing potential operational disruptions. The expertise behind designing and manufacturing inline centrifugal pumps comes from decades of research and development, focusing on refining the pump’s performance while ensuring sustainability. Manufacturers adhere to stringent quality standards, subjecting these pumps to rigorous testing protocols to ensure they meet industry demands. This commitment to quality and performance not only underscores their reliability but also cements the authority of manufacturers in providing solutions that address both common and unique pumping challenges. Trust plays a pivotal role in the adoption of inline centrifugal pumps. As an investment, users need assurance that the equipment will perform as expected under various scenarios. Reputable manufacturers provide comprehensive documentation and support, including installation guides, operational manuals, and customer service access. This support system ensures users feel confident in their purchase, knowing they have access to expert advice and assistance whenever needed. In conclusion, inline centrifugal pumps represent a convergence of innovation, efficiency, and reliability. Their compact design, combined with advanced technological features, makes them ideal for various industrial applications. The focus on energy efficiency, user experience, and quality assurance places these pumps at the forefront of industry solutions, providing users with confidence in their operational capabilities and long-term value. As industries continue to evolve, inline centrifugal pumps are poised to remain a central component in achieving seamless, efficient, and sustainable operations.

One of the key aspects contributing to the user experience with inline centrifugal pumps is their user-friendly interface. Modern inline centrifugal pumps incorporate advanced technology features such as digital controllers and remote monitoring systems. These features offer real-time data analysis, enabling operators to make informed decisions and adjustments to optimize performance. The ability to monitor and control pump operations remotely not only enhances efficiency but also allows for proactive maintenance, thus preventing potential operational disruptions. The expertise behind designing and manufacturing inline centrifugal pumps comes from decades of research and development, focusing on refining the pump’s performance while ensuring sustainability. Manufacturers adhere to stringent quality standards, subjecting these pumps to rigorous testing protocols to ensure they meet industry demands. This commitment to quality and performance not only underscores their reliability but also cements the authority of manufacturers in providing solutions that address both common and unique pumping challenges. Trust plays a pivotal role in the adoption of inline centrifugal pumps. As an investment, users need assurance that the equipment will perform as expected under various scenarios. Reputable manufacturers provide comprehensive documentation and support, including installation guides, operational manuals, and customer service access. This support system ensures users feel confident in their purchase, knowing they have access to expert advice and assistance whenever needed. In conclusion, inline centrifugal pumps represent a convergence of innovation, efficiency, and reliability. Their compact design, combined with advanced technological features, makes them ideal for various industrial applications. The focus on energy efficiency, user experience, and quality assurance places these pumps at the forefront of industry solutions, providing users with confidence in their operational capabilities and long-term value. As industries continue to evolve, inline centrifugal pumps are poised to remain a central component in achieving seamless, efficient, and sustainable operations.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024