-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 17, 2025 02:18

Back to list

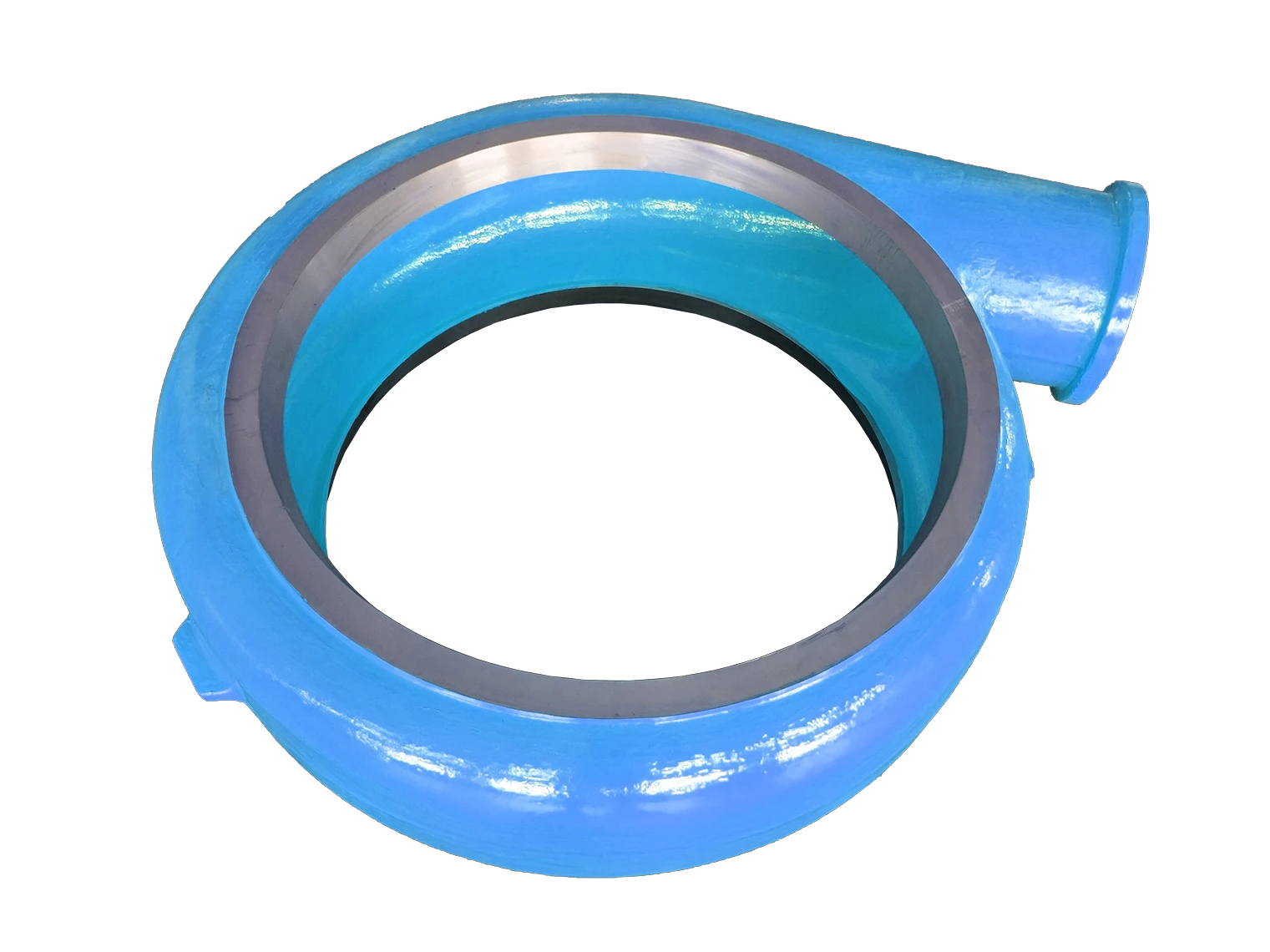

industrial sludge pump

Industrial sludge pumps are a vital component in the process of managing waste in various industries. Their primary function is to handle thick, abrasive, and corrosive sludges which are often byproducts of industrial operations. With the increasing focus on environmental sustainability, the efficiency and effectiveness of sludge pumps have become crucial in maintaining ecological balance.

When considering the purchase of an industrial sludge pump, expertise in selecting the right equipment is indispensable. The choice of pump should be guided by a thorough understanding of the specific industrial requirements, such as the type of sludge, flow rate, and the head pressure needed. Consulting with manufacturers or seasoned industry professionals can provide valuable insights into the most suitable pump model and configuration for a given application. Trustworthiness in the manufacturer is an essential factor that influences the purchasing decision. Established brands with a history of reliability and customer satisfaction tend to provide better after-sales service and product warranties. Reviews and case studies can often provide an indicator of the pump's performance in real-world applications. The authoritativeness of a manufacturer is often reflected in their compliance with international standards and certifications. It is advisable to select pumps that meet ISO or ANSI standards, as these certifications often indicate adherence to high-quality manufacturing processes and materials. High-quality components reduce the risk of unexpected failures that could disrupt industrial processes. Real-world experience from other users can provide invaluable insights into the performance and maintenance of industrial sludge pumps. Online forums and industry conferences are excellent venues for gathering shared experiences and knowledge. Such platforms enable prospective buyers to make more informed decisions based on the collective experience of a broad user base. Ultimately, the successful implementation of an industrial sludge pump depends on a balanced consideration of its performance, efficiency, reliability, and environmental impact. As industries continue to emphasize sustainability and operational efficiency, the importance of selecting the right sludge pump has never been more pronounced. Embracing newer technologies and maintaining informed purchasing practices will ensure that industrial operations remain efficient and environmentally responsible.

When considering the purchase of an industrial sludge pump, expertise in selecting the right equipment is indispensable. The choice of pump should be guided by a thorough understanding of the specific industrial requirements, such as the type of sludge, flow rate, and the head pressure needed. Consulting with manufacturers or seasoned industry professionals can provide valuable insights into the most suitable pump model and configuration for a given application. Trustworthiness in the manufacturer is an essential factor that influences the purchasing decision. Established brands with a history of reliability and customer satisfaction tend to provide better after-sales service and product warranties. Reviews and case studies can often provide an indicator of the pump's performance in real-world applications. The authoritativeness of a manufacturer is often reflected in their compliance with international standards and certifications. It is advisable to select pumps that meet ISO or ANSI standards, as these certifications often indicate adherence to high-quality manufacturing processes and materials. High-quality components reduce the risk of unexpected failures that could disrupt industrial processes. Real-world experience from other users can provide invaluable insights into the performance and maintenance of industrial sludge pumps. Online forums and industry conferences are excellent venues for gathering shared experiences and knowledge. Such platforms enable prospective buyers to make more informed decisions based on the collective experience of a broad user base. Ultimately, the successful implementation of an industrial sludge pump depends on a balanced consideration of its performance, efficiency, reliability, and environmental impact. As industries continue to emphasize sustainability and operational efficiency, the importance of selecting the right sludge pump has never been more pronounced. Embracing newer technologies and maintaining informed purchasing practices will ensure that industrial operations remain efficient and environmentally responsible.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024