-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 22:10

Back to list

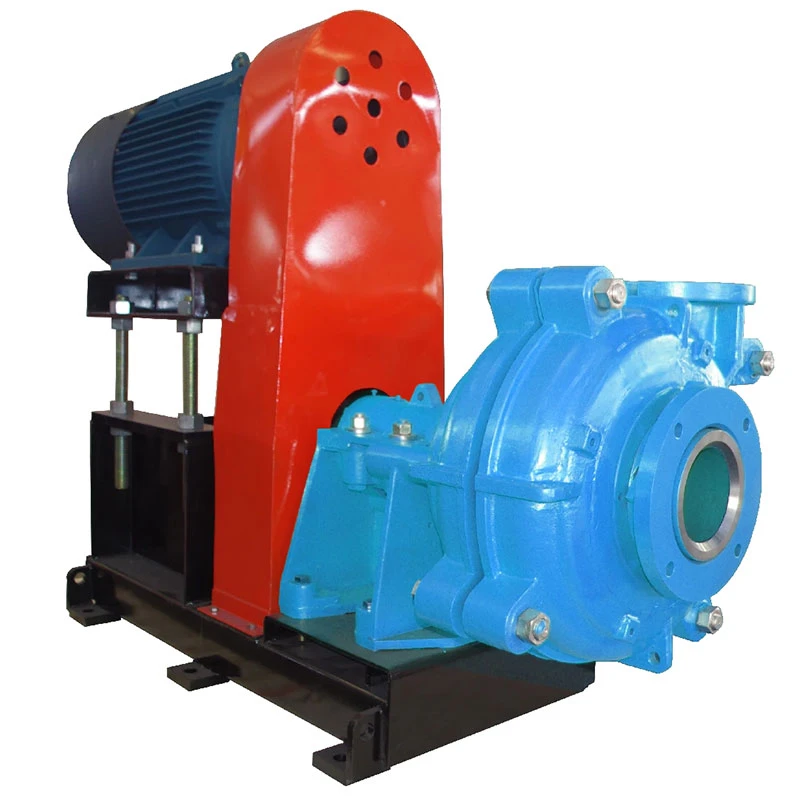

impeller use

Impellers are indispensable components in various industrial applications, serving as the heart of machinery that facilitates fluid movement. Primarily used in pumps, compressors, and turbines, understanding the operational excellence around impeller use can dramatically improve system efficiency, optimize performance, and extend equipment lifespan.

Consider impeller coatings for applications dealing with abrasive fluids or high-speed operations. Coatings such as ceramic or polymer-based solutions offer an added layer of protection against erosion and cavitation damage, a common phenomenon where vapor bubbles form and collapse, causing significant surface damage. By mitigating these effects, coatings help maintain the impeller’s structural integrity over time. Innovative technologies such as computational fluid dynamics (CFD) and 3D printing are reshaping impeller development, allowing for precise design customization and rapid prototyping. With CFD, manufacturers can simulate flow conditions and optimize impeller shapes and sizes for specific applications even before casting. 3D printing enables rapid iteration and cost-effective production of complex geometries that improve fluid movement efficiency. Energy efficiency is increasingly vital in today’s eco-conscious landscape. Impellers directly impact a system’s energy consumption; hence, optimal design and operational strategies focusing on reducing drag and enhancing flow efficiency are crucial. Implementing variable speed drives (VSDs) in tandem with impellers adapts operational speed to real-time needs, conserving energy without sacrificing performance. In conclusion, impeller use is a cornerstone of many mechanical systems, influencing efficiency, performance longevity, and operational cost. Professionals across industries must prioritize a meticulous selection process, tailored maintenance schedules, and adopt innovative design solutions to harness the full potential of impellers. Such informed practices not only elevate machinery performance but also align with sustainable operation protocols, marking a step forward in industrial equipment management.

Consider impeller coatings for applications dealing with abrasive fluids or high-speed operations. Coatings such as ceramic or polymer-based solutions offer an added layer of protection against erosion and cavitation damage, a common phenomenon where vapor bubbles form and collapse, causing significant surface damage. By mitigating these effects, coatings help maintain the impeller’s structural integrity over time. Innovative technologies such as computational fluid dynamics (CFD) and 3D printing are reshaping impeller development, allowing for precise design customization and rapid prototyping. With CFD, manufacturers can simulate flow conditions and optimize impeller shapes and sizes for specific applications even before casting. 3D printing enables rapid iteration and cost-effective production of complex geometries that improve fluid movement efficiency. Energy efficiency is increasingly vital in today’s eco-conscious landscape. Impellers directly impact a system’s energy consumption; hence, optimal design and operational strategies focusing on reducing drag and enhancing flow efficiency are crucial. Implementing variable speed drives (VSDs) in tandem with impellers adapts operational speed to real-time needs, conserving energy without sacrificing performance. In conclusion, impeller use is a cornerstone of many mechanical systems, influencing efficiency, performance longevity, and operational cost. Professionals across industries must prioritize a meticulous selection process, tailored maintenance schedules, and adopt innovative design solutions to harness the full potential of impellers. Such informed practices not only elevate machinery performance but also align with sustainable operation protocols, marking a step forward in industrial equipment management.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024