-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 04:02

Back to list

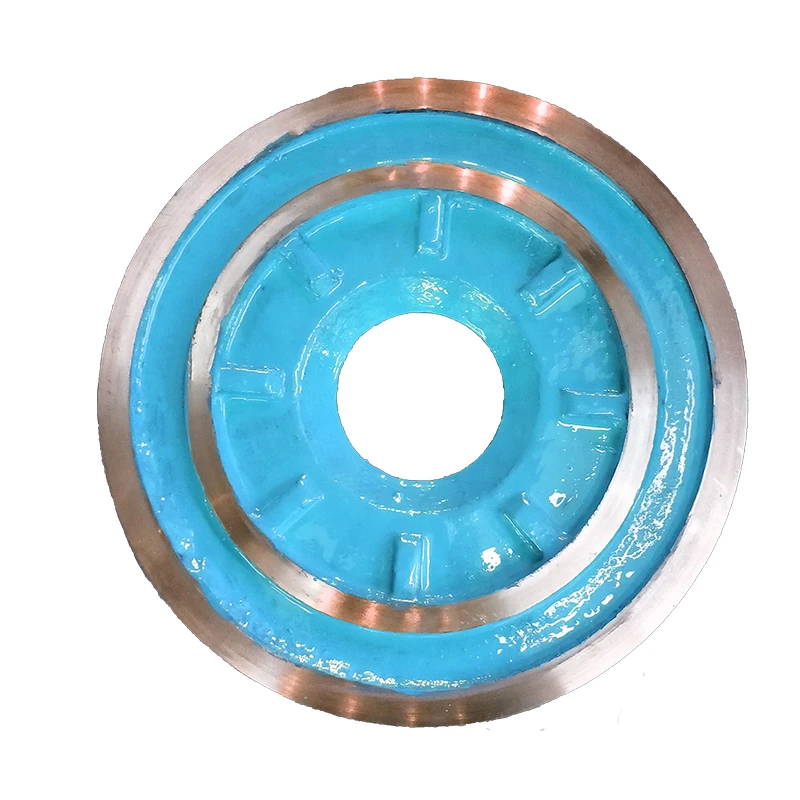

impeller types and uses

Navigating the diverse world of impellers reveals a fascinating array of types and uses, each tailored to meet specific industrial demands. As the heart of centrifugal pumps and a key component in fluid dynamics, impellers play a critical role in various sectors. Understanding their nuances can significantly impact efficiency and performance in various applications.

Multi-stage Impellers are configurations where multiple impellers are used in sequence to achieve higher pressures. This type is essential in high-rise building water supply systems, boiler feed operations, and deep well water extraction, where consistent high pressure is necessary for system efficiency. Choosing the right impeller involves careful consideration of several factors, including fluid properties, desired pressure and flow rates, the presence of solids, and specific application requirements. Industrial sectors must align impeller selection with operational demands to enhance productivity, minimize downtime, and ensure cost-effective performance. Staying ahead in the competitive landscape necessitates not only selecting the appropriate impeller but also understanding its maintenance needs and operational limits. Regular inspections, coupled with an informed choice based on precise application requirements, form the foundation of optimal system performance. Professionals in the field continually enhance their expertise through interaction with cutting-edge technology suppliers and participation in knowledge-sharing platforms. This continuous learning and adaptation process fosters a deeper understanding of impeller functionalities, allowing for their strategic deployment across a wide range of industrial sectors. The nuanced approach to selecting impeller types underscores the importance of expertise in maximizing equipment longevity and ensuring seamless operations. Emphasizing robust research and evidence-based practices enhances trust in decision-making processes, reinforcing the pivotal role of impellers in various industrial applications.

Multi-stage Impellers are configurations where multiple impellers are used in sequence to achieve higher pressures. This type is essential in high-rise building water supply systems, boiler feed operations, and deep well water extraction, where consistent high pressure is necessary for system efficiency. Choosing the right impeller involves careful consideration of several factors, including fluid properties, desired pressure and flow rates, the presence of solids, and specific application requirements. Industrial sectors must align impeller selection with operational demands to enhance productivity, minimize downtime, and ensure cost-effective performance. Staying ahead in the competitive landscape necessitates not only selecting the appropriate impeller but also understanding its maintenance needs and operational limits. Regular inspections, coupled with an informed choice based on precise application requirements, form the foundation of optimal system performance. Professionals in the field continually enhance their expertise through interaction with cutting-edge technology suppliers and participation in knowledge-sharing platforms. This continuous learning and adaptation process fosters a deeper understanding of impeller functionalities, allowing for their strategic deployment across a wide range of industrial sectors. The nuanced approach to selecting impeller types underscores the importance of expertise in maximizing equipment longevity and ensuring seamless operations. Emphasizing robust research and evidence-based practices enhances trust in decision-making processes, reinforcing the pivotal role of impellers in various industrial applications.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024