-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 13, 2025 20:51

Back to list

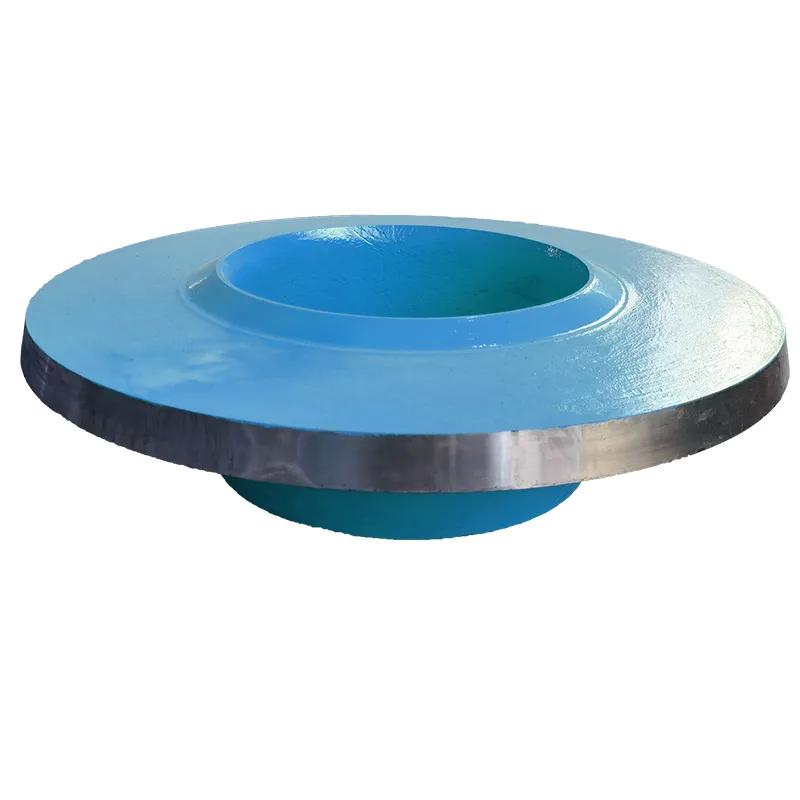

Pump Wear Parts SP15041 Metal

Delving into the world of impeller suppliers unveils a nuanced and intricate landscape, essential for numerous industrial applications. Impellers, pivotal components in pumps, turbines, and compressors, have an overarching influence on the efficiency and performance of these systems. Sourcing from reputable suppliers is therefore crucial, not only for the sake of ensuring mechanical efficacy but for maintaining operational reliability and longevity.

Moreover, an often-overlooked aspect is the environmental stewardship practiced by top-tier impeller suppliers. In the quest to improve operational sustainability, several leading suppliers engage in eco-conscious manufacturing processes, incorporating recycled materials and reducing waste. This alignment with green initiatives not only appeals to environmentally-focused enterprises but bolsters the credibility of the supplier within the market. Recent advancements led by authoritative suppliers explore the integration of smart technologies into impeller systems. Utilizing IoT devices, these systems offer predictive maintenance capabilities, alerting operators to potential issues before they manifest. This innovation underscores the suppliers’ commitment to not only solving current challenges but anticipating future needs, thereby boosting the operational intelligence of the entire facility. In an industry where precision and reliability are paramount, the choice of impeller supplier is a decision that carries substantial weight. Evaluating potential suppliers through the lens of experience, material expertise, authoritativeness, and trustworthiness allows businesses to foster a supply chain that supports strategic goals, mitigates risks, and enhances overall performance. In conclusion, selecting the right impeller supplier transcends mere transactional dynamics. It involves partnering with experts who possess a profound understanding of diverse industrial needs, a partner that thrives on technological innovation, adheres rigorously to quality standards, fosters trust through reliable service, and commits to sustainable practices. This comprehensive approach not only ensures superior product performance but contributes significantly to the long-term success and sustainability of the operations they support.

Moreover, an often-overlooked aspect is the environmental stewardship practiced by top-tier impeller suppliers. In the quest to improve operational sustainability, several leading suppliers engage in eco-conscious manufacturing processes, incorporating recycled materials and reducing waste. This alignment with green initiatives not only appeals to environmentally-focused enterprises but bolsters the credibility of the supplier within the market. Recent advancements led by authoritative suppliers explore the integration of smart technologies into impeller systems. Utilizing IoT devices, these systems offer predictive maintenance capabilities, alerting operators to potential issues before they manifest. This innovation underscores the suppliers’ commitment to not only solving current challenges but anticipating future needs, thereby boosting the operational intelligence of the entire facility. In an industry where precision and reliability are paramount, the choice of impeller supplier is a decision that carries substantial weight. Evaluating potential suppliers through the lens of experience, material expertise, authoritativeness, and trustworthiness allows businesses to foster a supply chain that supports strategic goals, mitigates risks, and enhances overall performance. In conclusion, selecting the right impeller supplier transcends mere transactional dynamics. It involves partnering with experts who possess a profound understanding of diverse industrial needs, a partner that thrives on technological innovation, adheres rigorously to quality standards, fosters trust through reliable service, and commits to sustainable practices. This comprehensive approach not only ensures superior product performance but contributes significantly to the long-term success and sustainability of the operations they support.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024