-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 13, 2025 03:39

Back to list

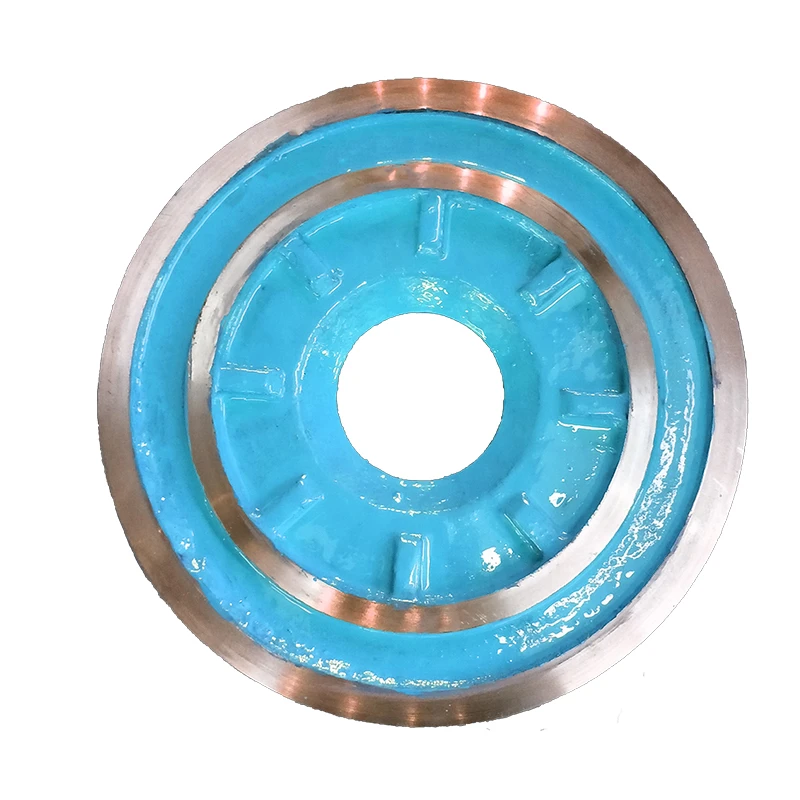

Pump Wear Parts SPR65041 Rubber

In industries where fluid dynamics and efficiency play a crucial role, the choice of materials for critical components can significantly impact performance. The stainless steel impeller stands out as a reliable and efficient choice, especially in applications involving corrosive environments or high-velocity flows. This article explores the unique benefits of using stainless steel for impellers, drawing from real-world experiences and industry expertise that highlight its superiority over other materials.

Trust in stainless steel impellers is further reinforced by their proven track record in high-stakes applications. Companies that have transitioned from alternative materials to stainless steel have reported not only improved system efficiency but also considerable savings in maintenance costs. For example, a leading chemical processing firm noted a 30% increase in pump efficiency and a reduction in downtime after switching to stainless steel impellers, underscoring their cost-effectiveness and reliability. Moreover, stainless steel impellers are increasingly becoming a popular choice due to their environment-friendly characteristics. Unlike impellers made from composite materials that may pose disposal challenges, stainless steel is fully recyclable. This is particularly significant in the current sustainability-focused market, where industries are seeking to minimize their environmental footprint while maintaining operational efficacy. In conclusion, the stainless steel impeller marks itself as a pinnacle of reliability, efficiency, and sustainability in fluid management systems. Whether it's resisting corrosive environments, minimizing wear in abrasive conditions, or enhancing system reliability, the advantages of stainless steel impellers are substantive and well-documented. For industries striving for longevity and performance excellence, stainless steel impellers not only meet the mark but set the standard. Trust the resilience of stainless steel, guided by expertise and proven effectiveness, to optimize your industrial applications and reduce long-term operational costs.

Trust in stainless steel impellers is further reinforced by their proven track record in high-stakes applications. Companies that have transitioned from alternative materials to stainless steel have reported not only improved system efficiency but also considerable savings in maintenance costs. For example, a leading chemical processing firm noted a 30% increase in pump efficiency and a reduction in downtime after switching to stainless steel impellers, underscoring their cost-effectiveness and reliability. Moreover, stainless steel impellers are increasingly becoming a popular choice due to their environment-friendly characteristics. Unlike impellers made from composite materials that may pose disposal challenges, stainless steel is fully recyclable. This is particularly significant in the current sustainability-focused market, where industries are seeking to minimize their environmental footprint while maintaining operational efficacy. In conclusion, the stainless steel impeller marks itself as a pinnacle of reliability, efficiency, and sustainability in fluid management systems. Whether it's resisting corrosive environments, minimizing wear in abrasive conditions, or enhancing system reliability, the advantages of stainless steel impellers are substantive and well-documented. For industries striving for longevity and performance excellence, stainless steel impellers not only meet the mark but set the standard. Trust the resilience of stainless steel, guided by expertise and proven effectiveness, to optimize your industrial applications and reduce long-term operational costs.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024