-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 04:45

Back to list

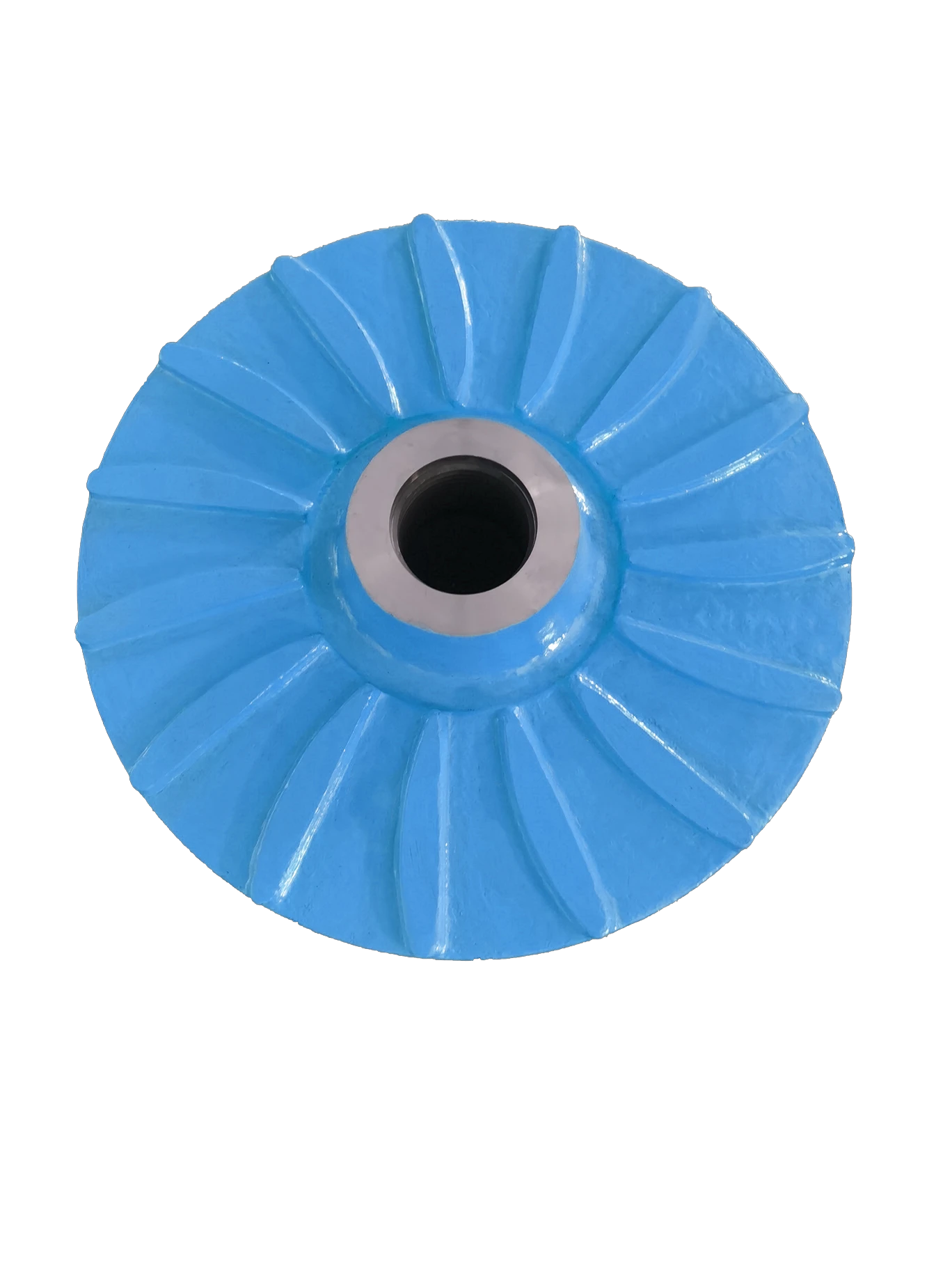

impeller slurry pump

In industries dealing with highly abrasive and corrosive materials, the impeller slurry pump stands as a critical piece of equipment. These pumps are specifically engineered to handle thick, abrasive slurries that would otherwise severely damage conventional pumps. Through real-world experience and advanced expertise, these robust machines showcase impressive durability and functionality.

The authoritative standing of slurry pump manufacturers is reinforced by their certifications and adherence to international safety and quality standards. These credentials are a testament to their commitment to producing high-caliber equipment that meets stringent operational demands. Moreover, industry-leading manufacturers continuously invest in research and development, striving to innovate and refine their pump designs to meet evolving industrial challenges. Customer trust is built through transparency and reliability. Leading manufacturers provide extensive warranties and after-sales support, ensuring that their customers have access to necessary resources to keep their operations running smoothly. This encompasses everything from routine maintenance advice to the availability of authentic replacement parts, ensuring that each pump's lifespan is maximized for optimal performance. The expertise required to properly select and maintain impeller slurry pumps cannot be understated. Professionals skilled in understanding the nuances of fluid handling and impeller dynamics are integral to the seamless integration of these pumps into industrial systems. Their insights enable precise customization, ensuring that each application is met with the pump best suited to its unique requirements. In conclusion, the impeller slurry pump is a cornerstone in industries where handling abrasive and corrosive materials is routine. Its sophisticated design, coupled with robust materials and innovative technology, underscore its essential role in maintaining efficiency and productivity. The trust vested in these pumps by various sectors is a reflection of their proven reliability and the expertise of the professionals who design and maintain them. As industries continue to demand higher efficiency and durability from their equipment, the impeller slurry pump remains a vital asset, adapting to meet new challenges with unwavering reliability.

The authoritative standing of slurry pump manufacturers is reinforced by their certifications and adherence to international safety and quality standards. These credentials are a testament to their commitment to producing high-caliber equipment that meets stringent operational demands. Moreover, industry-leading manufacturers continuously invest in research and development, striving to innovate and refine their pump designs to meet evolving industrial challenges. Customer trust is built through transparency and reliability. Leading manufacturers provide extensive warranties and after-sales support, ensuring that their customers have access to necessary resources to keep their operations running smoothly. This encompasses everything from routine maintenance advice to the availability of authentic replacement parts, ensuring that each pump's lifespan is maximized for optimal performance. The expertise required to properly select and maintain impeller slurry pumps cannot be understated. Professionals skilled in understanding the nuances of fluid handling and impeller dynamics are integral to the seamless integration of these pumps into industrial systems. Their insights enable precise customization, ensuring that each application is met with the pump best suited to its unique requirements. In conclusion, the impeller slurry pump is a cornerstone in industries where handling abrasive and corrosive materials is routine. Its sophisticated design, coupled with robust materials and innovative technology, underscore its essential role in maintaining efficiency and productivity. The trust vested in these pumps by various sectors is a reflection of their proven reliability and the expertise of the professionals who design and maintain them. As industries continue to demand higher efficiency and durability from their equipment, the impeller slurry pump remains a vital asset, adapting to meet new challenges with unwavering reliability.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024