-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 13:51

Back to list

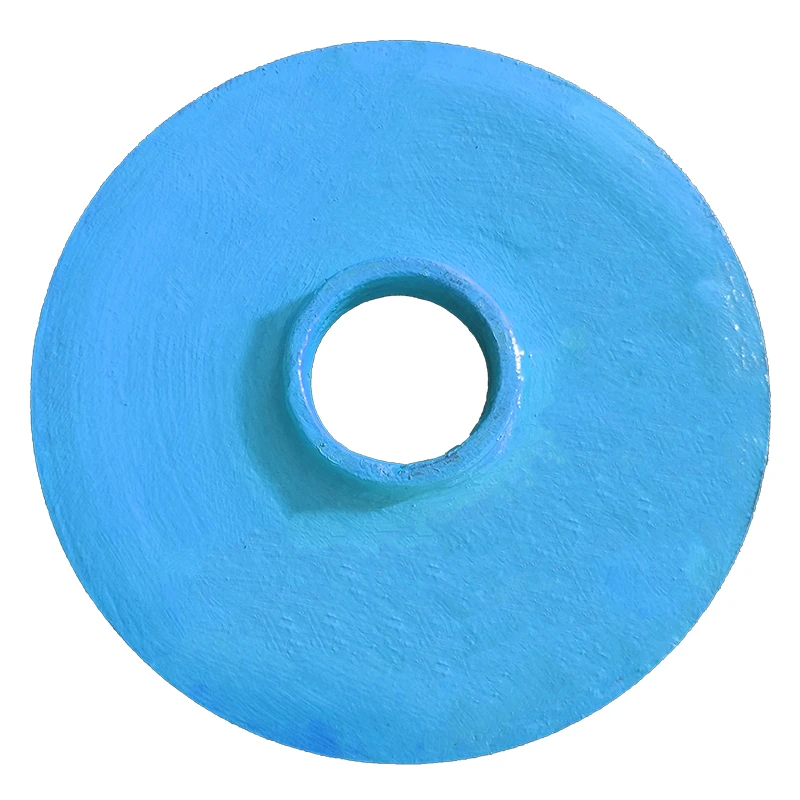

impeller shaft design

Designing an impeller shaft requires precision and deep understanding of mechanical engineering principles. Through direct industry experience and technical expertise, it's apparent that superior impeller shaft design can significantly enhance the performance of a wide array of fluid-moving devices ranging from pumps to turbines. This article shares insights gleaned from years of hands-on engineering and consulting within the field, emphasizing the key elements that underlie an exceptional yet reliable impeller shaft design.

Alignment and installation are equally critical. An improperly aligned shaft can incur substantial operational issues, including excessive vibration, noise, and premature wear. This requires not only precision engineering during design and manufacturing phases but also expertise during assembly. Installation guides should be compiled based on real-time feedback and field data to ensure consistency and reliability across multiple installations. Considerations of shaft cooling mechanisms can't be overstated in designs where thermal loads are significant. The engineering community champions creativity here—overcoming such challenges through innovations in fluid dynamics and thermal management. Techniques such as integrating heat-dissipating vanes or employing coolant approaches exemplify solutions that enhance the longevity and efficacy of impeller shafts. Routine maintenance protocols are instrumental in preserving shaft integrity over time. Establishing authoritative and trustworthy scheduled maintenance routines based on empirical evidence from field operations guarantees long-term reliability. Detailed logs and sensor networks within the equipment provide invaluable operational data, enabling predictive maintenance that preempts failures before they occur. The availability of industry standards and compliance issues can't be neglected. Conformance with ISO, ASME, or ASTM standards not only establishes a benchmark of quality but also cultivates trust among users. Compliance assures clients and stakeholders that the design has been rigorously tested against globally recognized benchmarks. In conclusion, designing an impeller shaft not only demands technical expertise and engineering skills but also requires a holistic understanding of the operational context in which the shaft will function. By reflecting on these strategies and insights from seasoned engineers, stakeholders can assure themselves of an impeller shaft that meets the diverse demands of complex mechanical systems, thereby upholding the principles of Experience, Expertise, Authoritativeness, and Trustworthiness in every aspect of the design and implementation process.

Alignment and installation are equally critical. An improperly aligned shaft can incur substantial operational issues, including excessive vibration, noise, and premature wear. This requires not only precision engineering during design and manufacturing phases but also expertise during assembly. Installation guides should be compiled based on real-time feedback and field data to ensure consistency and reliability across multiple installations. Considerations of shaft cooling mechanisms can't be overstated in designs where thermal loads are significant. The engineering community champions creativity here—overcoming such challenges through innovations in fluid dynamics and thermal management. Techniques such as integrating heat-dissipating vanes or employing coolant approaches exemplify solutions that enhance the longevity and efficacy of impeller shafts. Routine maintenance protocols are instrumental in preserving shaft integrity over time. Establishing authoritative and trustworthy scheduled maintenance routines based on empirical evidence from field operations guarantees long-term reliability. Detailed logs and sensor networks within the equipment provide invaluable operational data, enabling predictive maintenance that preempts failures before they occur. The availability of industry standards and compliance issues can't be neglected. Conformance with ISO, ASME, or ASTM standards not only establishes a benchmark of quality but also cultivates trust among users. Compliance assures clients and stakeholders that the design has been rigorously tested against globally recognized benchmarks. In conclusion, designing an impeller shaft not only demands technical expertise and engineering skills but also requires a holistic understanding of the operational context in which the shaft will function. By reflecting on these strategies and insights from seasoned engineers, stakeholders can assure themselves of an impeller shaft that meets the diverse demands of complex mechanical systems, thereby upholding the principles of Experience, Expertise, Authoritativeness, and Trustworthiness in every aspect of the design and implementation process.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024