-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 00:19

Back to list

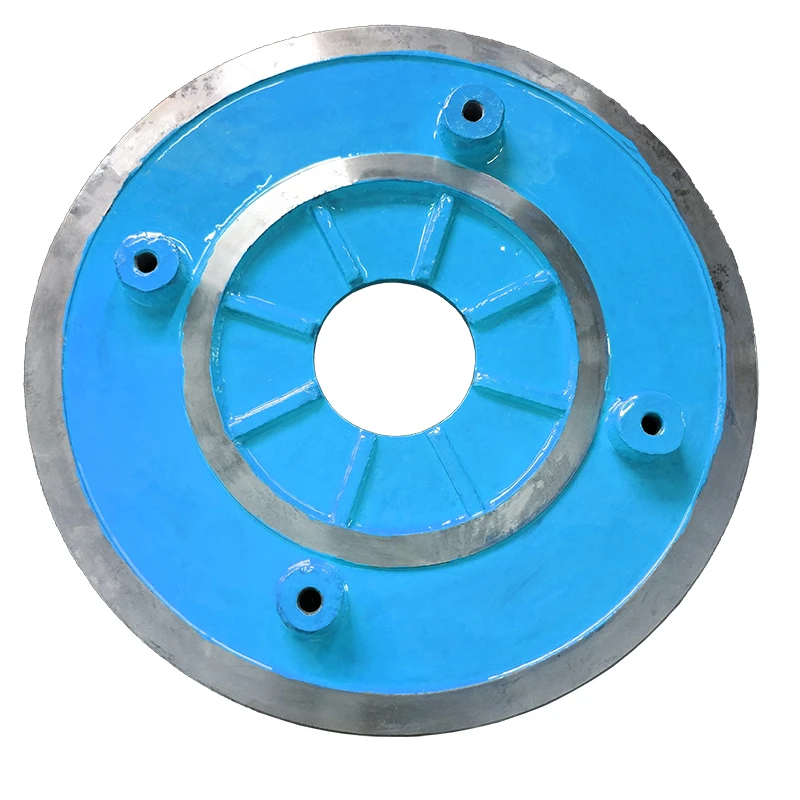

impeller selection

Selecting the right impeller for your specific application is a crucial decision that can significantly impact the efficiency and performance of your systems. As an experienced engineer who has worked extensively with various types of impellers across different industries, I can guide you through the intricacies of impeller selection, emphasizing real-world insights and advanced technical knowledge.

Another critical factor is the impeller's diameter and its rotational speed, both of which directly influence the flow capacity and pressure generation of the pump. Larger diameters and higher speeds generally increase flow and pressure, but balancing these aspects with system compatibility is key to avoiding issues such as cavitation, which can severely damage both the impeller and the pump. Experts also stress the importance of precision in impeller trimming, a process that involves adjusting the impeller diameter to better match the exact requirements of a system. This customization can lead to significant energy savings and reduced operational costs over the lifespan of the equipment. Real-world experience underscores the importance of pairing impeller selection with a thorough understanding of system hydraulics and specifications. Collaborating with suppliers who offer expertise in engineering and profound product knowledge is invaluable. These professionals can provide detailed guidance on performance curves, ensuring the selected impeller meets specific demands without compromising efficiency or reliability. Investing time in robust research and seeking expert opinion helps establish a trust-based relationship with manufacturers. Ensure that they provide detailed documentation and testing data which back up their recommendations. This transparency not only enhances trust but also empowers you to make informed decisions based on empirical evidence rather than speculation. In conclusion, the selection of an impeller is a multidimensional decision that should harmonize with the operational needs and environmental conditions of your application. Expertise and a thorough comprehension of how impeller characteristics translate into functional benefits in the field will undoubtedly contribute to optimized performance, longevity, and reliability of your systems. Prioritizing collaboration with experienced partners and investing in high-quality materials and design can decisively advance your operations while securing a resolute foothold in achieving superior flow dynamics.

Another critical factor is the impeller's diameter and its rotational speed, both of which directly influence the flow capacity and pressure generation of the pump. Larger diameters and higher speeds generally increase flow and pressure, but balancing these aspects with system compatibility is key to avoiding issues such as cavitation, which can severely damage both the impeller and the pump. Experts also stress the importance of precision in impeller trimming, a process that involves adjusting the impeller diameter to better match the exact requirements of a system. This customization can lead to significant energy savings and reduced operational costs over the lifespan of the equipment. Real-world experience underscores the importance of pairing impeller selection with a thorough understanding of system hydraulics and specifications. Collaborating with suppliers who offer expertise in engineering and profound product knowledge is invaluable. These professionals can provide detailed guidance on performance curves, ensuring the selected impeller meets specific demands without compromising efficiency or reliability. Investing time in robust research and seeking expert opinion helps establish a trust-based relationship with manufacturers. Ensure that they provide detailed documentation and testing data which back up their recommendations. This transparency not only enhances trust but also empowers you to make informed decisions based on empirical evidence rather than speculation. In conclusion, the selection of an impeller is a multidimensional decision that should harmonize with the operational needs and environmental conditions of your application. Expertise and a thorough comprehension of how impeller characteristics translate into functional benefits in the field will undoubtedly contribute to optimized performance, longevity, and reliability of your systems. Prioritizing collaboration with experienced partners and investing in high-quality materials and design can decisively advance your operations while securing a resolute foothold in achieving superior flow dynamics.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024