-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 11, 2025 18:07

Back to list

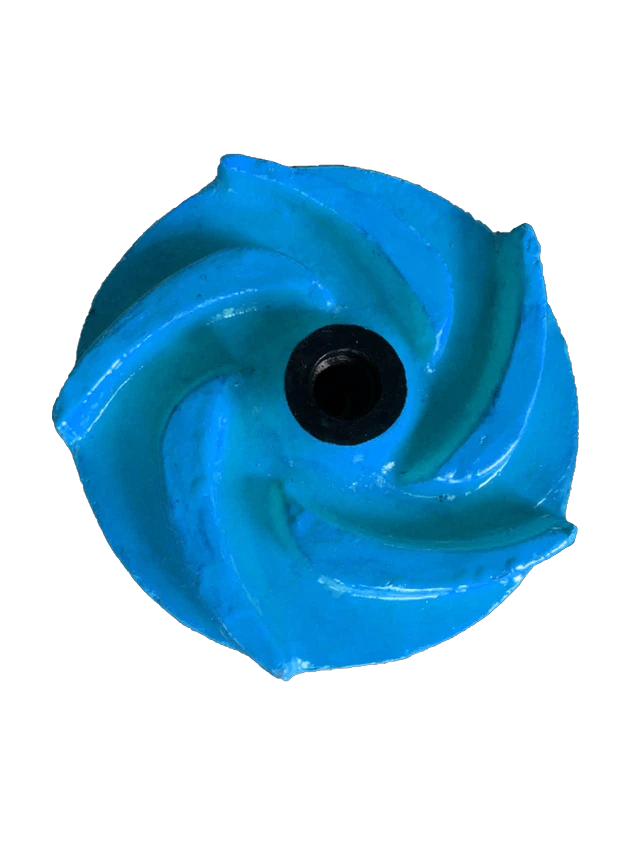

impeller pump

Impeller pumps serve as a crucial component in a myriad of industries, hailed for their robust design and efficiency in moving liquids. They operate through an impeller, which is a rotating component designed to move fluid by centrifugal force. The innovative engineering of these pumps has positioned them as indispensable tools across various applications, ranging from industrial to household use.

The expertise in maintenance of impeller pumps directly impacts their longevity and performance. Regular inspections and maintenance are paramount; this includes checking for signs of wear and tear, ensuring seals and bearings are in good condition, and confirming that the impeller is free from blockages. Industry veterans emphasize that establishing a proactive maintenance schedule can prevent unexpected downtimes, saving considerable time and resources in the long run. With growing environmental concerns and the need for sustainable solutions, impeller pump manufacturers are now focusing on energy efficiency. Innovations such as variable frequency drives (VFDs) are being integrated into pump systems to optimize energy use. VFDs regulate the pump’s speed, ensuring it operates at the most efficient point within its performance curve, thus significantly reducing energy consumption. This advancement not only contributes to lower operational costs but also aligns with global efforts towards reducing carbon footprints. The authority that impeller pumps wield is evidenced by their widespread adoption across sectors. From agriculture irrigation systems to advanced medical equipment, their reliability and efficiency make them a staple. The trustworthiness of these pumps is backed by stringent testing protocols and industry standards, ensuring they meet safety and quality benchmarks. Leading manufacturers invest heavily in research and development to continually refine their products, striving to exceed customer expectations and regulatory requirements. In conclusion, impeller pumps represent a synthesis of engineering excellence and practical utility. Their ability to adapt to a variety of operational challenges underscores their status as a go-to solution in fluid transportation. For industry professionals, leveraging the capabilities of impeller pumps effectively hinges on a deep understanding of both their mechanical properties and application environments. Continuous advancements in design and technology promise to further elevate the efficiency and reliability of these remarkable devices, solidifying their role in future innovations.

The expertise in maintenance of impeller pumps directly impacts their longevity and performance. Regular inspections and maintenance are paramount; this includes checking for signs of wear and tear, ensuring seals and bearings are in good condition, and confirming that the impeller is free from blockages. Industry veterans emphasize that establishing a proactive maintenance schedule can prevent unexpected downtimes, saving considerable time and resources in the long run. With growing environmental concerns and the need for sustainable solutions, impeller pump manufacturers are now focusing on energy efficiency. Innovations such as variable frequency drives (VFDs) are being integrated into pump systems to optimize energy use. VFDs regulate the pump’s speed, ensuring it operates at the most efficient point within its performance curve, thus significantly reducing energy consumption. This advancement not only contributes to lower operational costs but also aligns with global efforts towards reducing carbon footprints. The authority that impeller pumps wield is evidenced by their widespread adoption across sectors. From agriculture irrigation systems to advanced medical equipment, their reliability and efficiency make them a staple. The trustworthiness of these pumps is backed by stringent testing protocols and industry standards, ensuring they meet safety and quality benchmarks. Leading manufacturers invest heavily in research and development to continually refine their products, striving to exceed customer expectations and regulatory requirements. In conclusion, impeller pumps represent a synthesis of engineering excellence and practical utility. Their ability to adapt to a variety of operational challenges underscores their status as a go-to solution in fluid transportation. For industry professionals, leveraging the capabilities of impeller pumps effectively hinges on a deep understanding of both their mechanical properties and application environments. Continuous advancements in design and technology promise to further elevate the efficiency and reliability of these remarkable devices, solidifying their role in future innovations.

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024