-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 13, 2025 12:35

Back to list

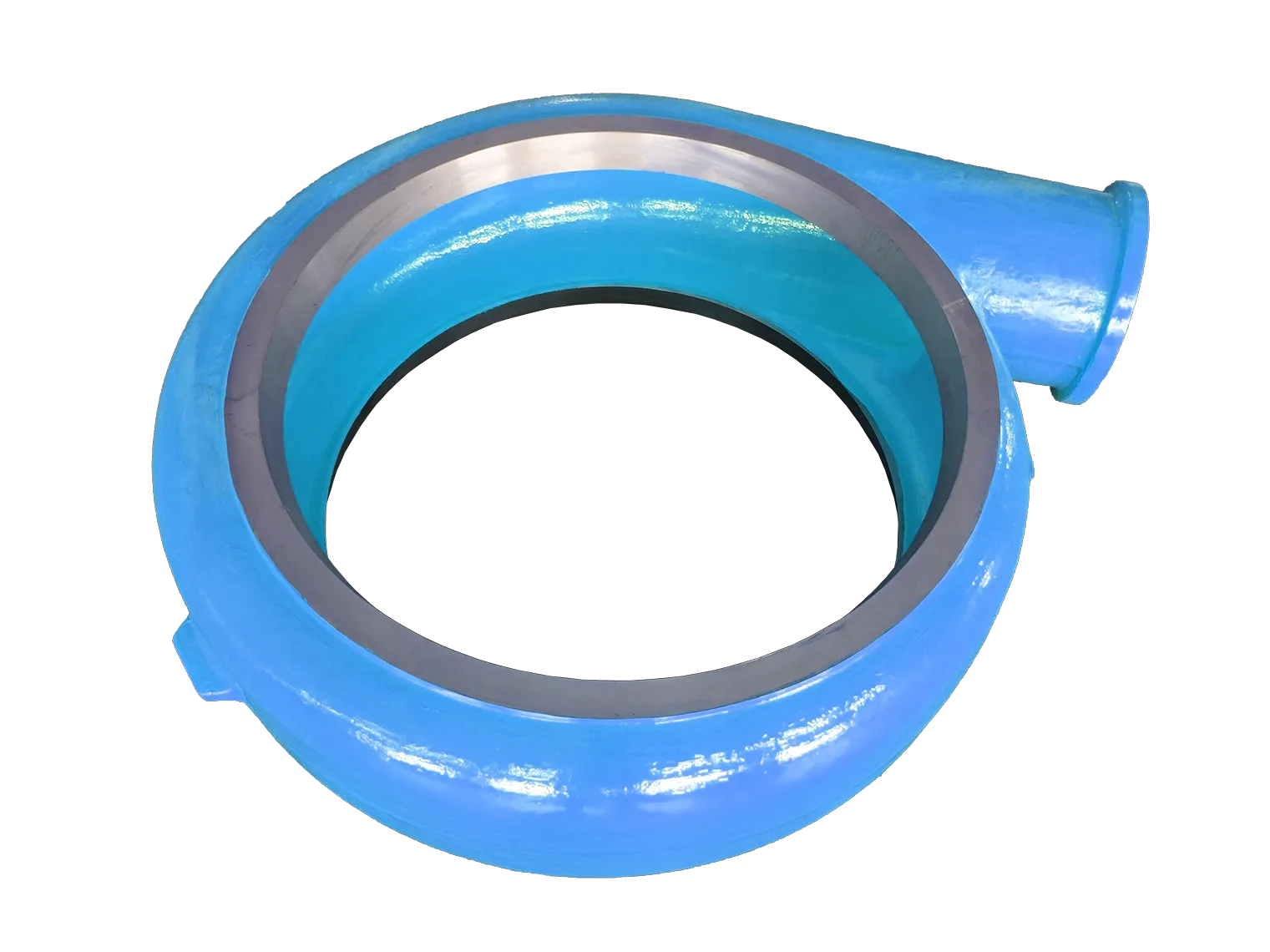

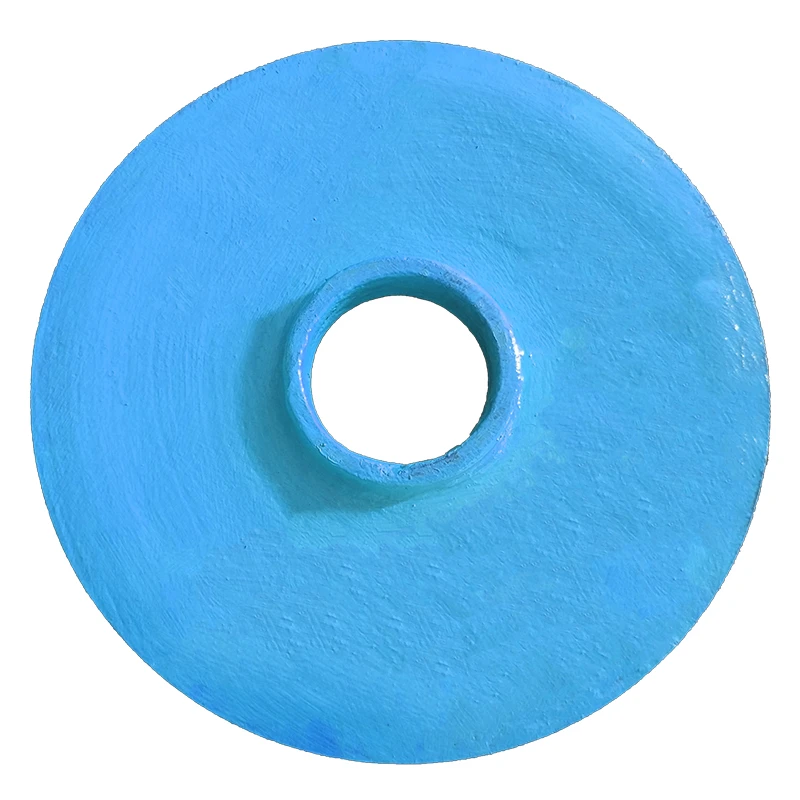

impeller price

In the intricate world of mechanical systems and fluid dynamics, the role of an impeller is indispensable. As a rotating component designed to move fluid, the impeller is foundational in countless industries—from automotive to water treatment. However, what often stirs discussions among industry professionals is not only its functionality but its pricing. Let's delve deep into the pricing dynamics of impellers, bolstered by experience, expertise, authoritativeness, and trustworthiness.

Moreover, having authoritative insights into suppliers and manufacturers can unlock significant cost-saving opportunities. Establishing partnerships with reputable manufacturers ensures access to quality impellers at competitive prices. Engaging with suppliers who prioritize innovation and efficiency can further enhance cost management. By fostering trust-based relationships within the supply chain, companies can benefit from bulk purchasing discounts and timely deliveries, minimizing operational hiccups. End-User Perspectives Leveraging Trust in Investment The trustworthiness of an impeller purchase hinges on transparency and reliability. For end-users, particularly those overseeing large-scale projects or industrial operations, the peace of mind that comes with a trustworthy purchase is invaluable. This is where thorough research and expert recommendations become vital. By consulting industry reviews, engaging in forums, and leveraging networks of professionals, purchasers can gain insights into the most reliable brands and models, ensuring their investments are secure and well-informed. Furthermore, engaging with service providers who offer warranties and robust after-sales support can elevate the trustworthiness of an impeller purchase. Such assurances often reflect a manufacturer’s confidence in their product's quality and longevity, providing end-users with an added layer of security. Conclusion Strategic Impeller Investment for Optimal Returns The landscape of impeller pricing is complex, interwoven with considerations of material choice, design sophistication, and market dynamics. Drawing on years of experience and expertise in the field enables individuals and companies to make informed decisions that balance cost with performance. By understanding these pricing elements and leveraging authoritative and trustful partnerships, businesses can strategically invest in impellers that offer optimal returns both in performance and lifecycle costs. As the demands on mechanical systems evolve, the strategic selection of impellers will remain critical in achieving sustainable operational success.

Moreover, having authoritative insights into suppliers and manufacturers can unlock significant cost-saving opportunities. Establishing partnerships with reputable manufacturers ensures access to quality impellers at competitive prices. Engaging with suppliers who prioritize innovation and efficiency can further enhance cost management. By fostering trust-based relationships within the supply chain, companies can benefit from bulk purchasing discounts and timely deliveries, minimizing operational hiccups. End-User Perspectives Leveraging Trust in Investment The trustworthiness of an impeller purchase hinges on transparency and reliability. For end-users, particularly those overseeing large-scale projects or industrial operations, the peace of mind that comes with a trustworthy purchase is invaluable. This is where thorough research and expert recommendations become vital. By consulting industry reviews, engaging in forums, and leveraging networks of professionals, purchasers can gain insights into the most reliable brands and models, ensuring their investments are secure and well-informed. Furthermore, engaging with service providers who offer warranties and robust after-sales support can elevate the trustworthiness of an impeller purchase. Such assurances often reflect a manufacturer’s confidence in their product's quality and longevity, providing end-users with an added layer of security. Conclusion Strategic Impeller Investment for Optimal Returns The landscape of impeller pricing is complex, interwoven with considerations of material choice, design sophistication, and market dynamics. Drawing on years of experience and expertise in the field enables individuals and companies to make informed decisions that balance cost with performance. By understanding these pricing elements and leveraging authoritative and trustful partnerships, businesses can strategically invest in impellers that offer optimal returns both in performance and lifecycle costs. As the demands on mechanical systems evolve, the strategic selection of impellers will remain critical in achieving sustainable operational success.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024