-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 12:47

Back to list

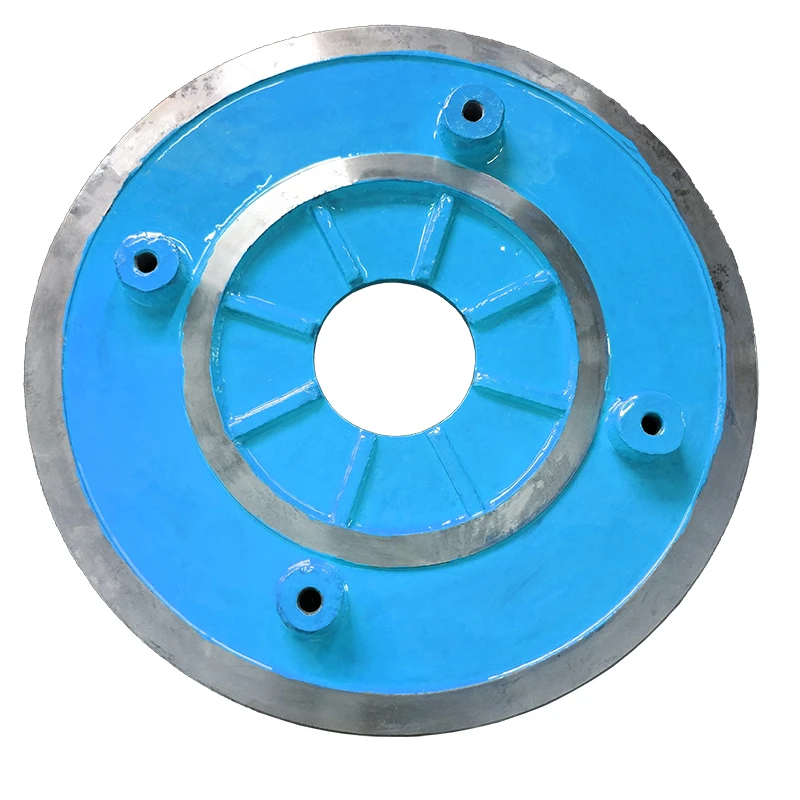

impeller material

Selecting the right impeller material is critical for ensuring the efficiency and longevity of pump systems across various industries. As a seasoned expert in this field, my experience has taught me that the choice of impeller material can significantly impact the performance, durability, and cost-effectiveness of pumps. In most cases, selecting the right material involves a careful evaluation of factors such as the medium being pumped, operating conditions, temperature, pressure, and potential for corrosion or wear.

For specific chemical handling or pharmaceutical applications, non-metallic materials like plastics or composites can be used. These materials, including polypropylene and PVDF (Polyvinylidene Fluoride), provide excellent chemical resistance and are lightweight, reducing the overall pump weight and energy consumption. Though less robust compared to metal counterparts, technological advancements have improved their wear and temperature resistances, making them suitable for a broader range of applications. When evaluating impeller materials, trustworthiness in product quality and the manufacturer's expertise are crucial elements. Manufacturers with a reputation for producing high-quality impeller materials often provide data on material performance, backed by rigorous testing and industry certifications. It’s essential to consider endorsements or partnerships with recognized industry authorities as they often indicate reliability and a track record of success in challenging applications. Furthermore, staying informed through case studies and reviews from industry peers provides insight into the real-world performance of different impeller materials. Such experiential data often reveals hidden challenges and solutions within specific application contexts, providing invaluable information beyond theoretical knowledge. In summary, the selection of impeller material is a multifaceted decision that involves understanding the specific demands of the application, evaluating the trade-offs between cost and performance, and relying on credible industry information. An impeller material that aligns well with the operating environment not only enhances efficiency but also significantly extends the service life of the pumping system, bringing about long-term savings and operational stability. Letting these principles guide your choice will ensure that your pump systems operate at peak performance, backed by the credibility and authoritative knowledge of seasoned experts in the field.

For specific chemical handling or pharmaceutical applications, non-metallic materials like plastics or composites can be used. These materials, including polypropylene and PVDF (Polyvinylidene Fluoride), provide excellent chemical resistance and are lightweight, reducing the overall pump weight and energy consumption. Though less robust compared to metal counterparts, technological advancements have improved their wear and temperature resistances, making them suitable for a broader range of applications. When evaluating impeller materials, trustworthiness in product quality and the manufacturer's expertise are crucial elements. Manufacturers with a reputation for producing high-quality impeller materials often provide data on material performance, backed by rigorous testing and industry certifications. It’s essential to consider endorsements or partnerships with recognized industry authorities as they often indicate reliability and a track record of success in challenging applications. Furthermore, staying informed through case studies and reviews from industry peers provides insight into the real-world performance of different impeller materials. Such experiential data often reveals hidden challenges and solutions within specific application contexts, providing invaluable information beyond theoretical knowledge. In summary, the selection of impeller material is a multifaceted decision that involves understanding the specific demands of the application, evaluating the trade-offs between cost and performance, and relying on credible industry information. An impeller material that aligns well with the operating environment not only enhances efficiency but also significantly extends the service life of the pumping system, bringing about long-term savings and operational stability. Letting these principles guide your choice will ensure that your pump systems operate at peak performance, backed by the credibility and authoritative knowledge of seasoned experts in the field.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024