-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 14, 2025 21:10

Back to list

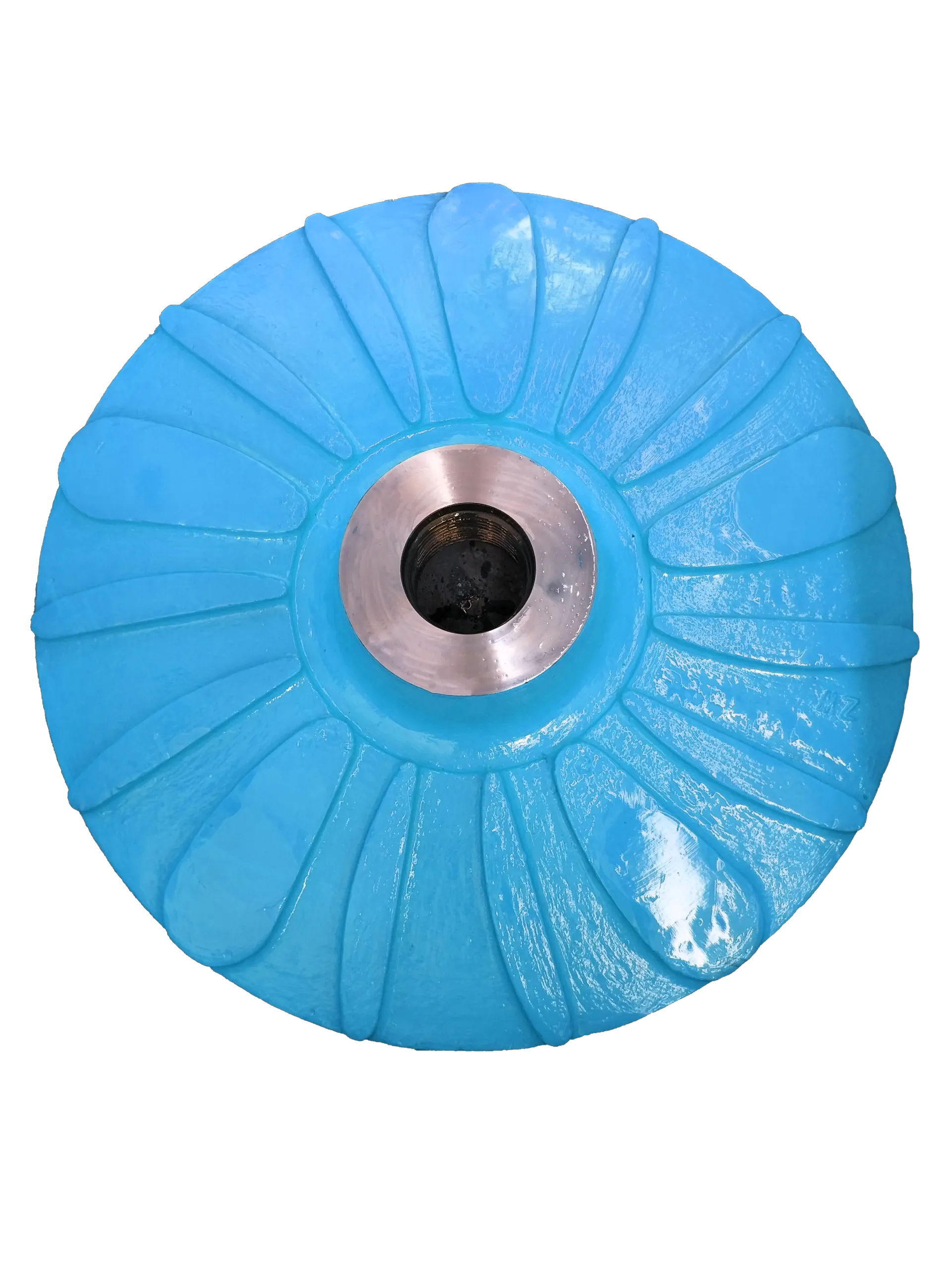

Horizontal Slurry Pumps MM1.5/1B-AH

The impeller diameter is a critical component in the engineering of various products, ranging from pumps and compressors to turbines and mixing devices. These round shaped structures are essential for efficient fluid dynamics, and their size directly affects the performance and efficiency of the equipment they are part of. Understanding the significance of impeller diameter, as well as how to select and optimize it, is vital for manufacturers seeking to maintain a competitive edge in the industry.

Authoritativeness comes from relying on standards and guidelines set by recognized organizations, such as the Hydraulic Institute’s guidelines for pumps, which provide rigorous criteria for selecting and evaluating impeller diameters for different pumping applications. Likewise, adhering to ASME standards in turbine design ensures reliability and safety, establishing the manufacturer as a credible figure in the industry. Trustworthiness is solidified through transparency and communication with clients, sharing insights derived from robust testing and field data. Demonstrating how impeller diameter impacts performance and cost savings can foster trust, enabling long-term relationships built on mutual understanding and benefit. An emerging trend is the customization of impeller diameters to meet specific client needs. Manufacturers offering bespoke designs can cater to niche markets, providing tailored solutions that optimize performance for unique applications. This client-focused approach not only boosts marketability but also strengthens client loyalty and brand reputation. The role of experience in optimizing impeller diameter cannot be overstated. Seasoned engineers draw on real-world projects and historical data to lend their expertise, anticipating challenges and proposing innovative solutions. They leverage their knowledge to refine impeller designs, ensuring they meet or exceed client expectations. In conclusion, while the impeller diameter may appear as a simple measurement, its optimized selection is a cornerstone of product efficiency and effectiveness. It embodies a fusion of experience, expertise, authoritativeness, and trustworthiness, with significant implications for product performance, energy consumption, and ultimately, operational excellence. Manufacturers must consider these facets to enhance the competitive value of their offerings in a dynamic and demanding market landscape.

Authoritativeness comes from relying on standards and guidelines set by recognized organizations, such as the Hydraulic Institute’s guidelines for pumps, which provide rigorous criteria for selecting and evaluating impeller diameters for different pumping applications. Likewise, adhering to ASME standards in turbine design ensures reliability and safety, establishing the manufacturer as a credible figure in the industry. Trustworthiness is solidified through transparency and communication with clients, sharing insights derived from robust testing and field data. Demonstrating how impeller diameter impacts performance and cost savings can foster trust, enabling long-term relationships built on mutual understanding and benefit. An emerging trend is the customization of impeller diameters to meet specific client needs. Manufacturers offering bespoke designs can cater to niche markets, providing tailored solutions that optimize performance for unique applications. This client-focused approach not only boosts marketability but also strengthens client loyalty and brand reputation. The role of experience in optimizing impeller diameter cannot be overstated. Seasoned engineers draw on real-world projects and historical data to lend their expertise, anticipating challenges and proposing innovative solutions. They leverage their knowledge to refine impeller designs, ensuring they meet or exceed client expectations. In conclusion, while the impeller diameter may appear as a simple measurement, its optimized selection is a cornerstone of product efficiency and effectiveness. It embodies a fusion of experience, expertise, authoritativeness, and trustworthiness, with significant implications for product performance, energy consumption, and ultimately, operational excellence. Manufacturers must consider these facets to enhance the competitive value of their offerings in a dynamic and demanding market landscape.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024