-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 06, 2025 06:25

Back to list

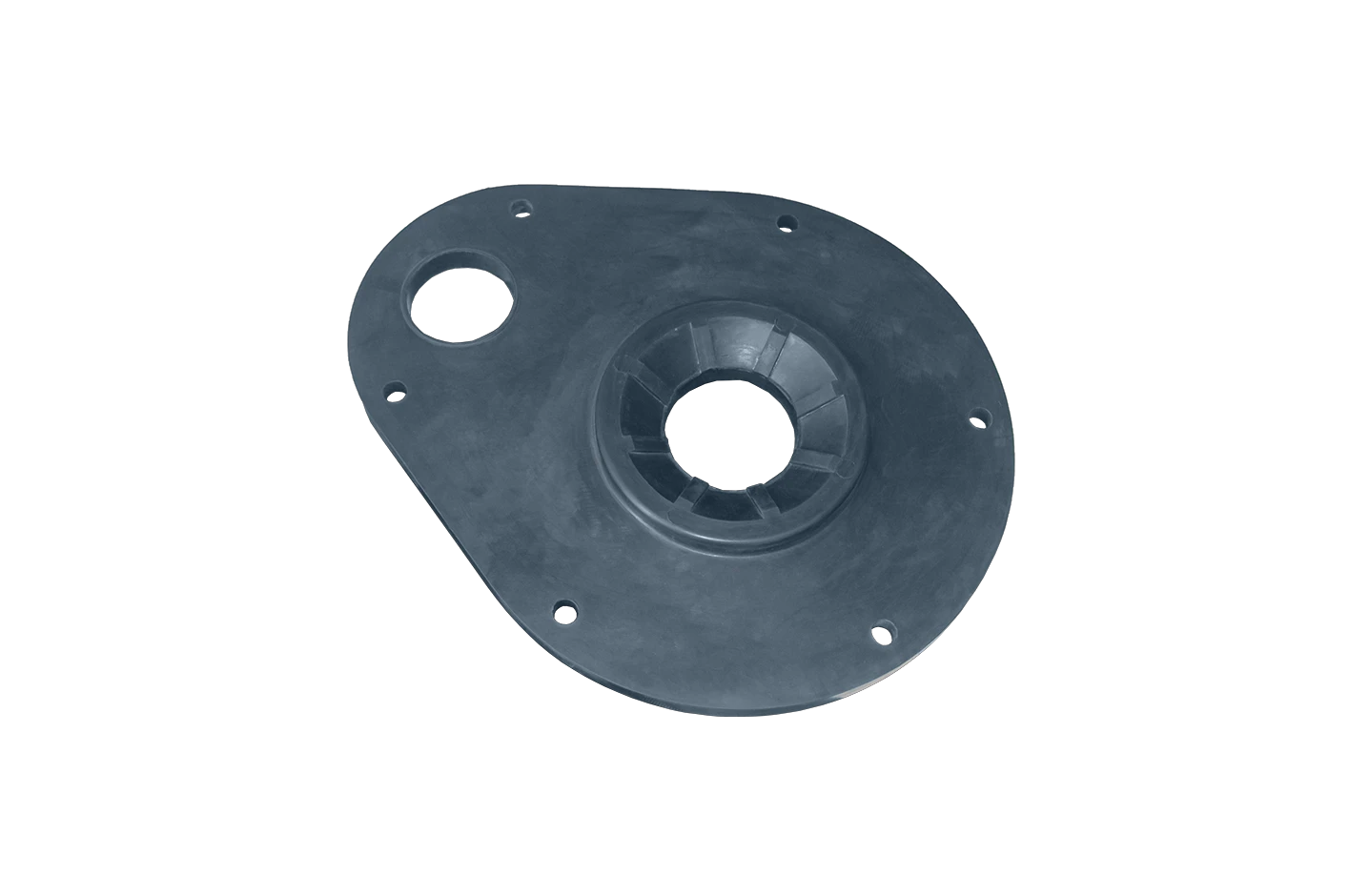

hs1 slurry pump parts

When delving into the complex world of industrial machinery, especially in sectors like mining or wastewater treatment, the term HS1 slurry pump parts often surfaces as a crucial component in ensuring operational efficiency. For those well-versed in industrial engineering, understanding the function and importance of these components is essential.

The precise fit and alignment of all these parts are crucial for the pump’s efficiency and reliability. Misalignments can cause vibrations that lead to premature wear or unexpected failures. Therefore, manufacturers of HS1 slurry pump parts emphasize quality control and precision engineering, leveraging advanced technologies and rigorous testing to meet stringent industry standards. In terms of expertise and authority, selecting the right HS1 slurry pump parts cannot be overstated. Consulting with experienced industry professionals and choosing certified products from reputable manufacturers can make a significant difference in pump performance. The credibility of a manufacturer is usually backed by certifications and compliance with international quality standards such as ISO 9001, which can be a benchmark for trustworthiness in the industry. However, it's not just about choosing high-quality parts; understanding the specific requirements of your application—such as the type of slurry, operational conditions, and desired output—is vital. Each industry may demand a slightly different configuration or material choice to optimize the pump's efficiency and reduce operational costs. For those involved in the procurement or maintenance of industrial machinery, developing an intimate knowledge of HS1 slurry pump parts translates into enhanced system performance, reliability, and safety. In conclusion, investing in top-tier HS1 slurry pump parts and coupling that investment with knowledge and experience in industrial applications constitutes a pragmatic approach to achieving operational excellence. The synergy of high-quality parts and deep industry understanding provides a foundation for maintaining efficiency and extending the longevity of critical machinery.

The precise fit and alignment of all these parts are crucial for the pump’s efficiency and reliability. Misalignments can cause vibrations that lead to premature wear or unexpected failures. Therefore, manufacturers of HS1 slurry pump parts emphasize quality control and precision engineering, leveraging advanced technologies and rigorous testing to meet stringent industry standards. In terms of expertise and authority, selecting the right HS1 slurry pump parts cannot be overstated. Consulting with experienced industry professionals and choosing certified products from reputable manufacturers can make a significant difference in pump performance. The credibility of a manufacturer is usually backed by certifications and compliance with international quality standards such as ISO 9001, which can be a benchmark for trustworthiness in the industry. However, it's not just about choosing high-quality parts; understanding the specific requirements of your application—such as the type of slurry, operational conditions, and desired output—is vital. Each industry may demand a slightly different configuration or material choice to optimize the pump's efficiency and reduce operational costs. For those involved in the procurement or maintenance of industrial machinery, developing an intimate knowledge of HS1 slurry pump parts translates into enhanced system performance, reliability, and safety. In conclusion, investing in top-tier HS1 slurry pump parts and coupling that investment with knowledge and experience in industrial applications constitutes a pragmatic approach to achieving operational excellence. The synergy of high-quality parts and deep industry understanding provides a foundation for maintaining efficiency and extending the longevity of critical machinery.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024