-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 25, 2025 05:34

Back to list

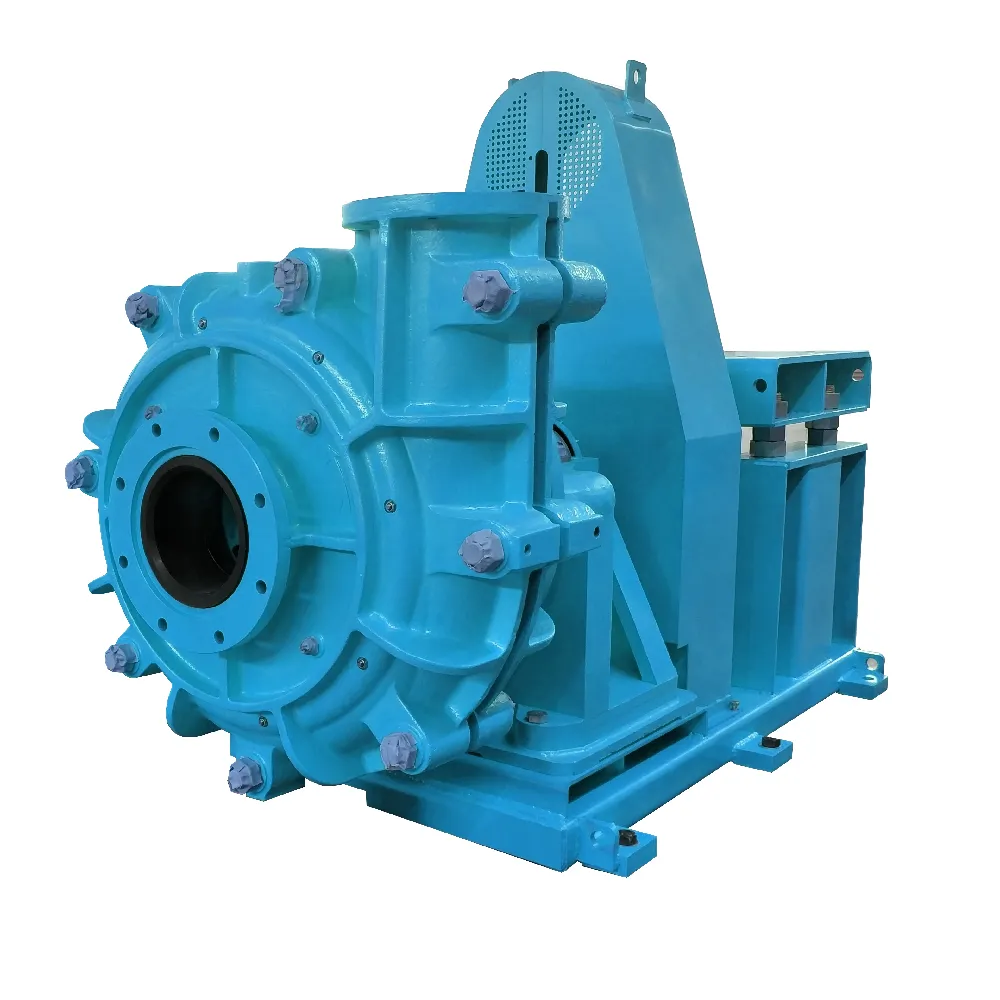

how does a slurry pump work

Slurry pumps are a crucial component in handling materials in industries such as mining, construction, agriculture, and waste management. Their primary function is to transport a mixture of fluid and solid particles, known as slurry, through pipelines over considerable distances. Understanding the operation of a slurry pump can offer significant insights into optimizing its use, ensuring longevity, and achieving higher efficiency in industrial processes.

Maintenance of slurry pumps is vital due to the abrasive nature of the materials they handle. Regular inspections and timely replacements of worn-out parts like impellers, liners, and seals are indispensable. Wear and tear can lead to decreased efficiency, increased energy consumption, and eventually complete pump failure if not addressed promptly. The installation of instrumentation and monitoring systems can substantially augment slurry pump performance. Technologies such as vibration sensors, bearing temperature sensors, and flow meters enable real-time monitoring of the pump's health and efficiency. Predictive maintenance can help identify potential failures before they occur, allowing for proactive management and reducing downtime. The importance of slurry pump selection and operation cannot be overstated when it comes to optimizing production processes. Customized slurry pumps that align with specific operational requirements often yield better performance. Key parameters to consider include the particle size, concentration, and corrosiveness of the slurry, as these factors directly affect pump design and material selection. In concluding, slurry pumps are indispensable for industries dealing with slurry transport. Their robustness and efficiency play a critical role in enhancing industrial productivity. By understanding the fundamental working principles of these pumps, implementing prudent maintenance strategies, and leveraging technological advancements, industries can significantly enhance their operational efficiencies. As the demands for resource efficiency and process optimization continue to rise, the role of slurry pumps becomes even more pronounced, underscoring the importance of making informed decisions regarding their design, selection, and maintenance.

Maintenance of slurry pumps is vital due to the abrasive nature of the materials they handle. Regular inspections and timely replacements of worn-out parts like impellers, liners, and seals are indispensable. Wear and tear can lead to decreased efficiency, increased energy consumption, and eventually complete pump failure if not addressed promptly. The installation of instrumentation and monitoring systems can substantially augment slurry pump performance. Technologies such as vibration sensors, bearing temperature sensors, and flow meters enable real-time monitoring of the pump's health and efficiency. Predictive maintenance can help identify potential failures before they occur, allowing for proactive management and reducing downtime. The importance of slurry pump selection and operation cannot be overstated when it comes to optimizing production processes. Customized slurry pumps that align with specific operational requirements often yield better performance. Key parameters to consider include the particle size, concentration, and corrosiveness of the slurry, as these factors directly affect pump design and material selection. In concluding, slurry pumps are indispensable for industries dealing with slurry transport. Their robustness and efficiency play a critical role in enhancing industrial productivity. By understanding the fundamental working principles of these pumps, implementing prudent maintenance strategies, and leveraging technological advancements, industries can significantly enhance their operational efficiencies. As the demands for resource efficiency and process optimization continue to rise, the role of slurry pumps becomes even more pronounced, underscoring the importance of making informed decisions regarding their design, selection, and maintenance.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024