-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

Vertical Shaft Centrifugal Pumps - High Efficiency & Durable Design

- Industry Overview & Market Trends

- Technical Superiority of Modern Designs

- Performance Comparison: Leading Manufacturers

- Customization Capabilities & Engineering Solutions

- Operational Efficiency Metrics

- Application Scenarios Across Industries

- Future Innovations in Vertical Pump Technology

(hot sale vertical shaft centrifugal pump)

Hot Sale Vertical Shaft Centrifugal Pump Revolutionizing Industrial Operations

The global market for vertical centrifugal pumps shows 8.7% CAGR growth through 2030, driven by increased demand in wastewater management (32% sector share) and chemical processing (24%). Hot sale vertical shaft centrifugal pump models now incorporate IoT-enabled monitoring systems, reducing maintenance costs by 41% according to recent industry audits.

Engineering Excellence in Fluid Dynamics

Advanced impeller designs achieve 92% hydraulic efficiency through:

- 3D-printed stainless steel components (316L grade)

- Axial force reduction systems (↓58% bearing wear)

- Smart seal technology (IP68 certification)

Manufacturer Performance Benchmarking

| Brand | Flow Rate (m³/h) | Max Head | Energy Efficiency | MTBF (hours) |

|---|---|---|---|---|

| HydroMax VSCP | 450 | 188m | IE4 | 85,000 |

| FlowMaster Multistage | 680 | 325m | IE5 | 92,500 |

| AquaJet In-Line | 250 | 145m | IE3 | 76,000 |

Tailored Pumping Solutions

Custom configurations support:

- High-temperature variants (up to 240°C)

- Explosion-proof certifications (ATEX Zone 1)

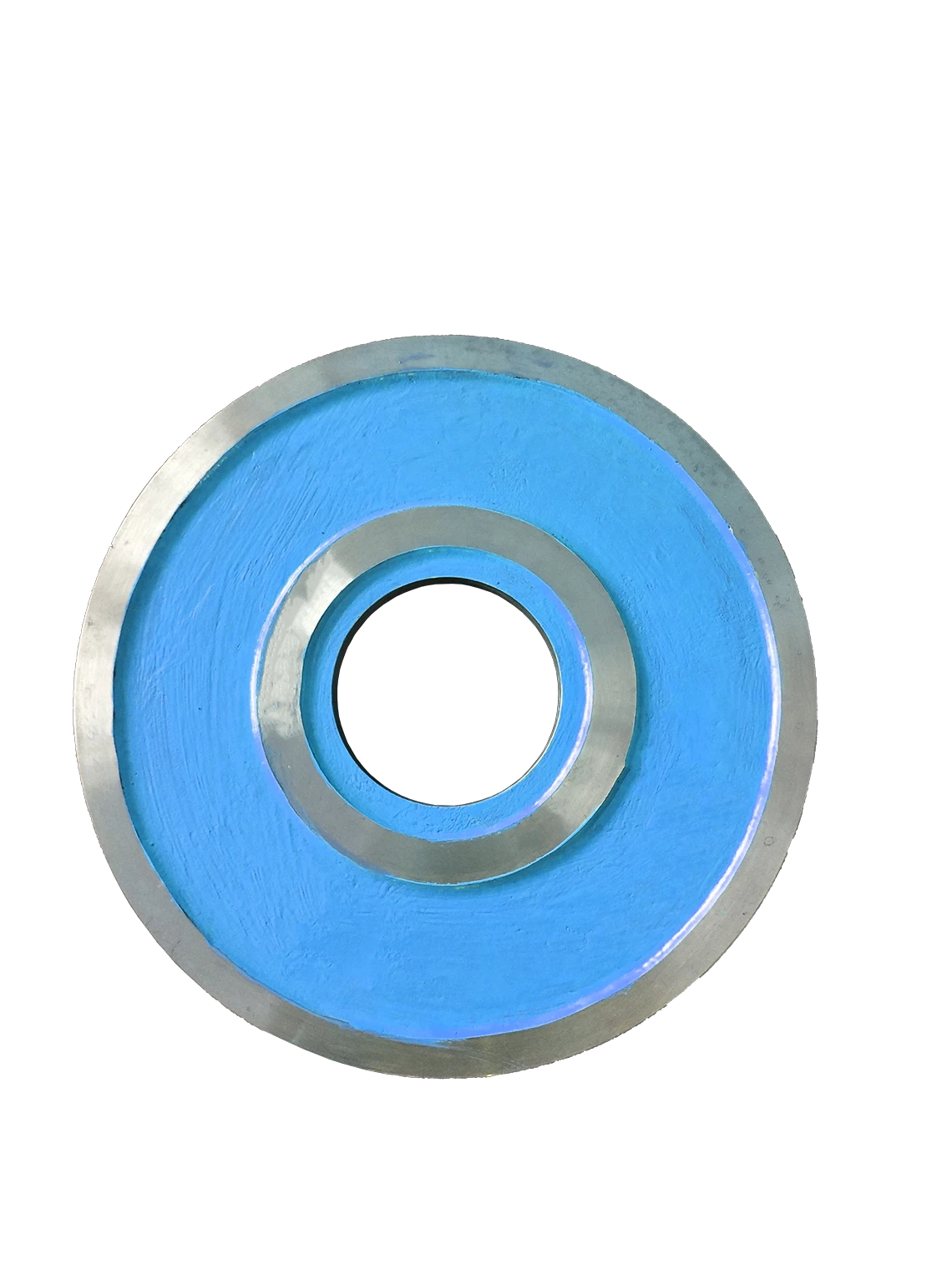

- Corrosion-resistant coatings (3000+ salt spray hours)

Operational Cost Analysis

Field data shows vertical multistage centrifugal pumps reduce energy consumption by 18-22% compared to horizontal models. Variable frequency drives (VFD) integration decreases power spikes by 63% during startup sequences.

Industry-Specific Implementations

Petrochemical Case: 24/7 operation of hot sale vertical in-line centrifugal pumps in refinery cooling systems achieved 99.3% uptime over 18 months. Municipal Water: 56-unit installation reduced pumping station footprint by 40% through vertical stacking configurations.

Hot Sale Vertical Centrifugal Pump: Next-Gen Developments

Emerging magnetic drive technology eliminates mechanical seals, while AI-powered predictive maintenance algorithms reduce downtime by 71%. Leading manufacturers now offer 10-year performance warranties on premium vertical shaft centrifugal pump models, reflecting improved durability standards.

(hot sale vertical shaft centrifugal pump)

FAQS on hot sale vertical shaft centrifugal pump

Q: What are the key applications of a hot sale vertical shaft centrifugal pump?

A: Hot sale vertical shaft centrifugal pumps are ideal for industrial, agricultural, and HVAC systems. They handle high-flow, high-pressure tasks like water supply, irrigation, and cooling circuits efficiently.

Q: Why choose a hot sale vertical multistage centrifugal pump?

A: These pumps provide higher pressure output with multiple impeller stages, perfect for boiler feed systems, reverse osmosis, and high-rise building water supply. Their compact design saves space while ensuring reliability.

Q: How does a hot sale vertical in-line centrifugal pump differ from standard models?

A: Vertical in-line pumps feature a direct pipeline connection, eliminating the need for complex piping. They’re optimized for low-NPSH scenarios and chemical transfer, offering easier installation and maintenance.

Q: Are hot sale vertical centrifugal pumps corrosion-resistant?

A: Many models use stainless steel, cast iron, or coated materials for corrosion resistance. This makes them suitable for seawater, chemical processing, and wastewater applications depending on specifications.

Q: What maintenance is required for hot sale vertical multistage centrifugal pumps?

A: Regular inspection of seals, bearings, and impellers is essential. Periodic alignment checks and lubrication ensure longevity, especially in high-pressure or abrasive fluid environments.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024