-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 04, 2025 02:05

Back to list

horizontal centrifugal pump vs vertical

When it comes to choosing between horizontal centrifugal pumps and vertical centrifugal pumps, understanding the nuances can greatly enhance process efficiency and system reliability. Each design offers specific advantages tailored to unique applications, making it essential to base the selection on informed insights.

However, vertical pumps necessitate a more specialized installation and maintenance protocol. The alignment of motor and pump components requires precision to avoid imbalance and wear issues. While this might entail higher initial setup costs, the payoff is a more compact and efficient operation that minimizes fluid transfer energy demands. Examining these pumps through the lens of authority and trustworthiness in the field involves tapping into reputable manufacturers and seeking validation through industry standards such as ISO certifications and compliance with international safety norms. This not only ensures the pump's credibility but also its adaptability to specific industry demands. For companies seeking longevity and performance, investing in a well-engineered pump system can result in significant long-term savings and productivity gains. Horizontal and vertical centrifugal pumps are each built to optimize specific environments, and understanding their distinct advantages can make a considerable difference in operational efficiency. Deciding between these two types requires a combination of site-specific requirements and future scalability considerations. Consulting with engineers or providers who have a proven track record in similar applications can be invaluable. By prioritizing these factors, businesses can ensure they choose a centrifugal pump that not only fits immediate needs but remains a reliable component of their infrastructure for years to come. Whether the choice is a horizontal design for its ease of access and maintenance or a vertical pump suited for its efficient space usage and deep well capabilities, the decision should be firmly grounded in both technological insight and practical experience. Through expert guidance and strategic selection, the right centrifugal pump can significantly elevate performance, sustainability, and operational success.

However, vertical pumps necessitate a more specialized installation and maintenance protocol. The alignment of motor and pump components requires precision to avoid imbalance and wear issues. While this might entail higher initial setup costs, the payoff is a more compact and efficient operation that minimizes fluid transfer energy demands. Examining these pumps through the lens of authority and trustworthiness in the field involves tapping into reputable manufacturers and seeking validation through industry standards such as ISO certifications and compliance with international safety norms. This not only ensures the pump's credibility but also its adaptability to specific industry demands. For companies seeking longevity and performance, investing in a well-engineered pump system can result in significant long-term savings and productivity gains. Horizontal and vertical centrifugal pumps are each built to optimize specific environments, and understanding their distinct advantages can make a considerable difference in operational efficiency. Deciding between these two types requires a combination of site-specific requirements and future scalability considerations. Consulting with engineers or providers who have a proven track record in similar applications can be invaluable. By prioritizing these factors, businesses can ensure they choose a centrifugal pump that not only fits immediate needs but remains a reliable component of their infrastructure for years to come. Whether the choice is a horizontal design for its ease of access and maintenance or a vertical pump suited for its efficient space usage and deep well capabilities, the decision should be firmly grounded in both technological insight and practical experience. Through expert guidance and strategic selection, the right centrifugal pump can significantly elevate performance, sustainability, and operational success.

Latest news

-

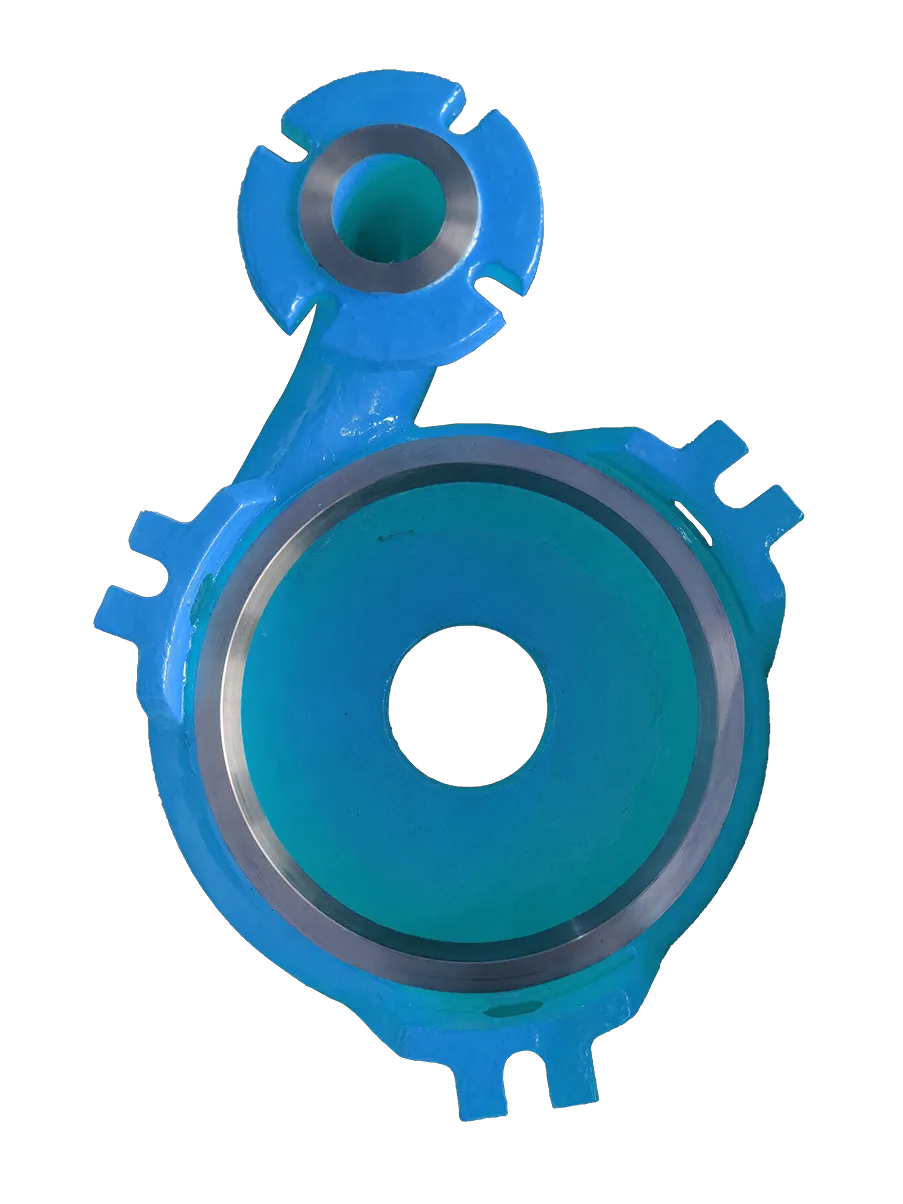

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024