-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 04, 2025 03:06

Back to list

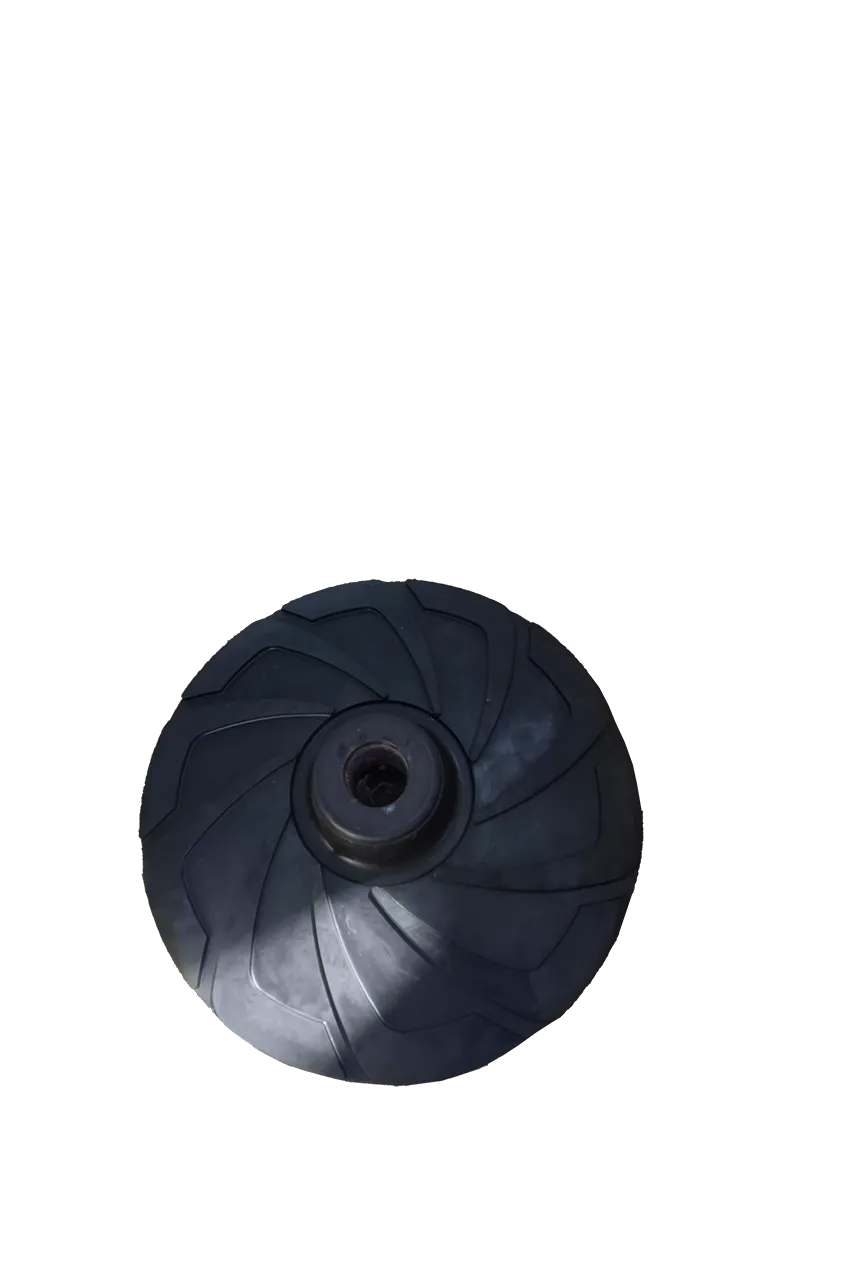

homemade slurry pump

In the world of fluid dynamics, the slurry pump stands as an invaluable tool, primarily engineered to handle the challenging task of transporting abrasive and viscous slurries. While commercial options are widely available, crafting a homemade slurry pump offers both an educational experience and a tailored solution that perfectly meets specific needs. This guide dives into the intricate aspects of creating a homemade slurry pump, combining expertise, real-world applications, safety considerations, and design efficiency.

Safety Protocols and Operational Training Safety cannot be overstated in the operation of a slurry pump. It's imperative to incorporate fail-safes like pressure relief valves and emergency shutoff switches in the design. Additionally, operational training for users should include understanding the specific risks involved, such as handling leaks or blockages safely, to mitigate potential hazards effectively. Real-world Application and Expert Insight Seasoned professionals frequently document that homemade slurry pumps, when designed and executed with precision, perform comparably to commercial counterparts in less demanding applications. The adaptability of a custom-built pump allows for seamless integration into specific environments, such as remote construction sites or localized industrial operations, where conventional pumps might be less effective due to their standardized design parameters. Advancing Knowledge through Collaboration Engaging with a community of enthusiasts and professionals can enhance the experience and outcome of building a slurry pump. Many have found value in forums and workshops dedicated to fluid mechanics and engineering. Sharing insights and troubleshooting can significantly impact the learning curve and success rates of homemade projects, turning individual efforts into collaborative advancements. Trust and Authority in Craftsmanship Credibility in homemade engineering projects is bolstered by rigorous testing and documentation. Maintaining a detailed log of material tests, flow rate measurements, and operational hours can substantiate the reliability and efficiency claims of the pump. Such documentation not only builds trust but also serves as a valuable resource for iterative design improvements and potential scalability. In the realm of DIY engineering, creating a homemade slurry pump is not just a technical pursuit; it's a testament to innovation, practicality, and mastery of mechanical design principles. This endeavor embodies the principles of sustainable engineering, providing bespoke solutions while fostering a deeper appreciation for the complexities of fluid transport systems. Through meticulous design, optimization, and community engagement, a homemade slurry pump stands as a beacon of personalized engineering excellence, capable of addressing niche applications that conventional solutions may overlook.

Safety Protocols and Operational Training Safety cannot be overstated in the operation of a slurry pump. It's imperative to incorporate fail-safes like pressure relief valves and emergency shutoff switches in the design. Additionally, operational training for users should include understanding the specific risks involved, such as handling leaks or blockages safely, to mitigate potential hazards effectively. Real-world Application and Expert Insight Seasoned professionals frequently document that homemade slurry pumps, when designed and executed with precision, perform comparably to commercial counterparts in less demanding applications. The adaptability of a custom-built pump allows for seamless integration into specific environments, such as remote construction sites or localized industrial operations, where conventional pumps might be less effective due to their standardized design parameters. Advancing Knowledge through Collaboration Engaging with a community of enthusiasts and professionals can enhance the experience and outcome of building a slurry pump. Many have found value in forums and workshops dedicated to fluid mechanics and engineering. Sharing insights and troubleshooting can significantly impact the learning curve and success rates of homemade projects, turning individual efforts into collaborative advancements. Trust and Authority in Craftsmanship Credibility in homemade engineering projects is bolstered by rigorous testing and documentation. Maintaining a detailed log of material tests, flow rate measurements, and operational hours can substantiate the reliability and efficiency claims of the pump. Such documentation not only builds trust but also serves as a valuable resource for iterative design improvements and potential scalability. In the realm of DIY engineering, creating a homemade slurry pump is not just a technical pursuit; it's a testament to innovation, practicality, and mastery of mechanical design principles. This endeavor embodies the principles of sustainable engineering, providing bespoke solutions while fostering a deeper appreciation for the complexities of fluid transport systems. Through meticulous design, optimization, and community engagement, a homemade slurry pump stands as a beacon of personalized engineering excellence, capable of addressing niche applications that conventional solutions may overlook.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024