-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 23, 2025 02:42

Back to list

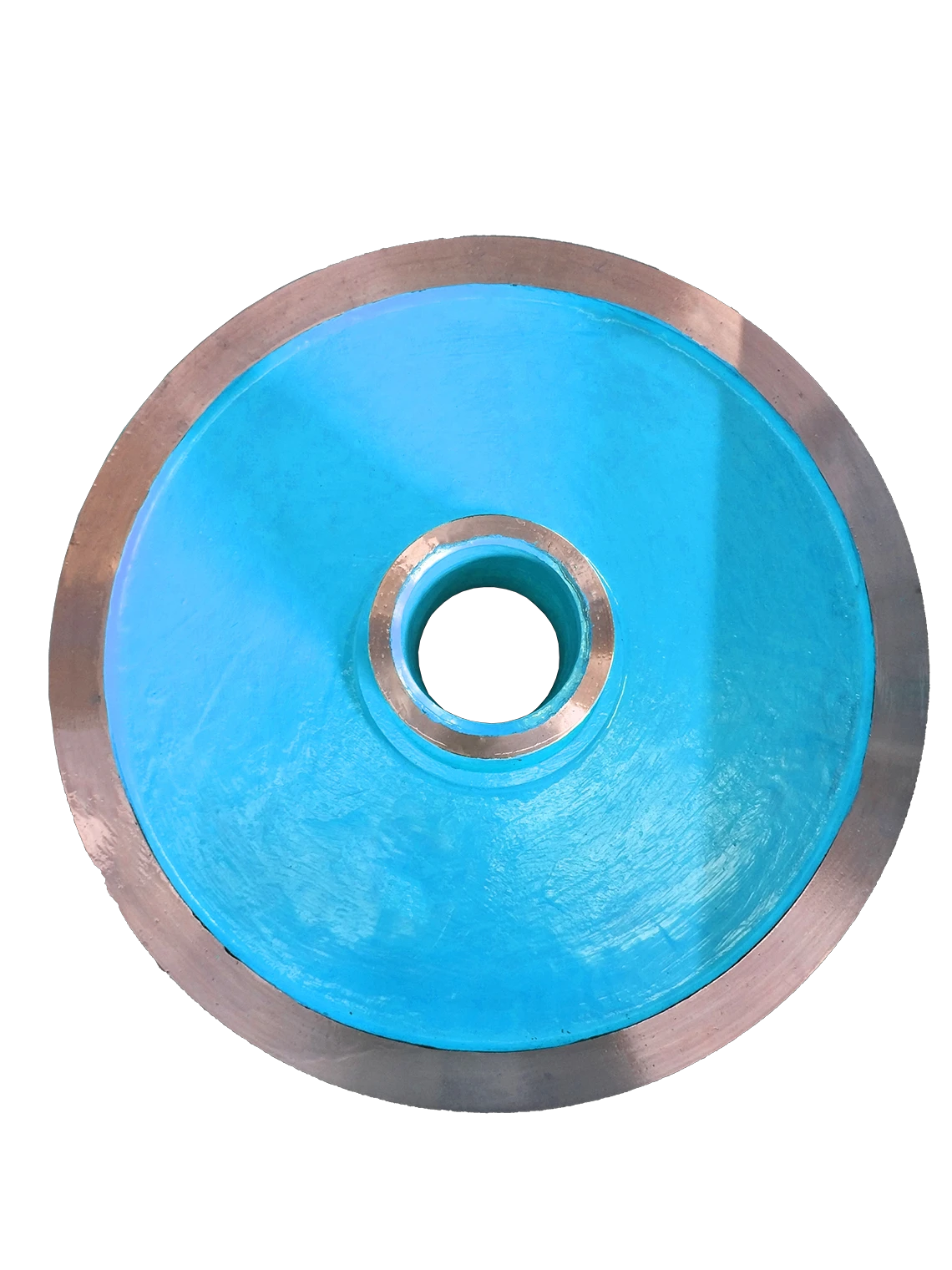

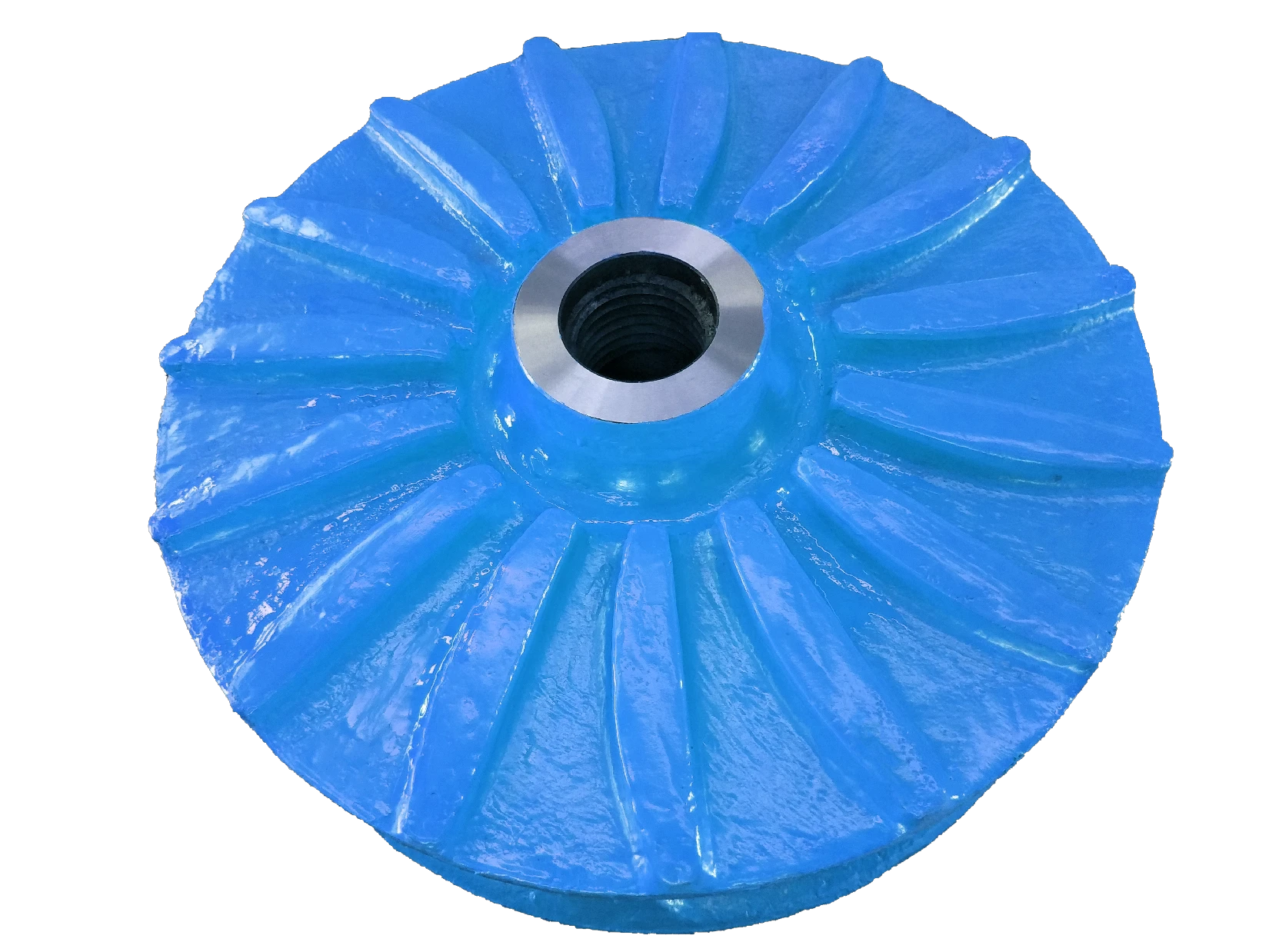

homemade slurry pump

Creating a homemade slurry pump can be a rewarding endeavor for those with a knack for engineering and DIY projects. Slurry pumps, commonly used in mining, dredging, and waste management, are essential for moving mixtures of liquids and solids. Understanding the fundamentals of their construction and operation can guide you in crafting a reliable and efficient homemade version.

Safety is another crucial consideration. Incorporating a pressure relief mechanism can prevent damage caused by sudden pressure spikes. Additionally, implementing a robust motor that corresponds to the power requirements of the pump ensures seamless operation. The assembly process requires meticulous attention to detail. Ensuring all components fit together precisely prevents operational inefficiencies and mechanical failures. Testing your homemade slurry pump under controlled conditions allows for adjustments and performance optimization before deploying it in real-world scenarios. Documenting each phase of the construction and testing process provides valuable insights and can serve as a reference for future projects. Sharing your experience and findings contributes to the broader community of DIY enthusiasts and can improve the design and operation of homemade slurry pumps. Continuous learning and embracing feedback are key for anyone venturing into creating machinery like slurry pumps. Engaging with online communities, attending workshops, and studying existing designs can enrich your knowledge and enhance the quality and performance of your homemade pump. Building a homemade slurry pump is not just about saving costs; it's a journey of understanding complex systems, honing craftsmanship skills, and creating a tool precisely tailored to specific needs. The satisfaction derived from a successfully operating pump is unmatched, showcasing the blend of creativity, technical knowledge, and practical application.

Safety is another crucial consideration. Incorporating a pressure relief mechanism can prevent damage caused by sudden pressure spikes. Additionally, implementing a robust motor that corresponds to the power requirements of the pump ensures seamless operation. The assembly process requires meticulous attention to detail. Ensuring all components fit together precisely prevents operational inefficiencies and mechanical failures. Testing your homemade slurry pump under controlled conditions allows for adjustments and performance optimization before deploying it in real-world scenarios. Documenting each phase of the construction and testing process provides valuable insights and can serve as a reference for future projects. Sharing your experience and findings contributes to the broader community of DIY enthusiasts and can improve the design and operation of homemade slurry pumps. Continuous learning and embracing feedback are key for anyone venturing into creating machinery like slurry pumps. Engaging with online communities, attending workshops, and studying existing designs can enrich your knowledge and enhance the quality and performance of your homemade pump. Building a homemade slurry pump is not just about saving costs; it's a journey of understanding complex systems, honing craftsmanship skills, and creating a tool precisely tailored to specific needs. The satisfaction derived from a successfully operating pump is unmatched, showcasing the blend of creativity, technical knowledge, and practical application.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024