-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 30, 2025 05:45

Back to list

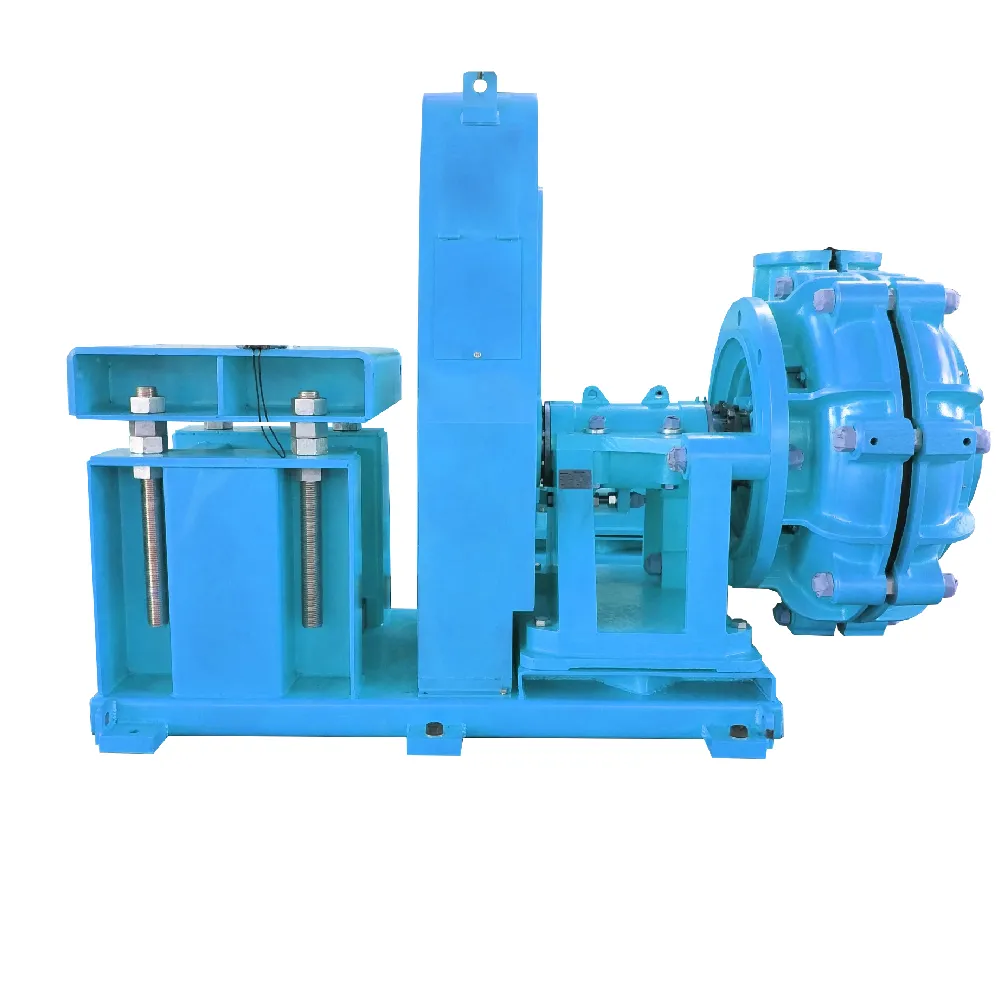

high pressure vertical pump

High pressure vertical pumps play a critical role in numerous industries, from oil and gas to water treatment, thanks to their exceptional efficiency and capacity to handle demanding tasks. If you've ever wondered about their inner workings, industry applications, and what sets them apart, here's a deep dive into this intriguing world.

From an experiential perspective, high pressure vertical pumps are favored for their easy maintenance and long-term cost efficiency. Their vertical design inherently allows for fewer mechanical seals and bearings; components that are typically prone to wear during operations. Consequently, this translates to fewer breakdowns and reduced downtime, a critical consideration for industries where continuous operation is non-negotiable. High pressure vertical pumps are also remarkably versatile. They can handle a range of fluids, from clean water to more viscous materials, including chemically aggressive or abrasive liquids. This versatility is crucial for industries such as mining, where the ability to pump slurry or other challenging fluids can significantly impact productivity and operational costs. For niche applications, customization becomes necessary, and manufacturers rise to the challenge by offering a range of impeller designs and material choices. Customization ensures that the pump not only meets industry standards but also surpasses them, tackling specific challenges head-on with measurable success. By understanding these facets — performance, expertise in design, authoritative testing, trust through certification, and real-world experiences — businesses can make informed decisions when investing in high pressure vertical pumps. As a result, they can ensure that their operations maintain high levels of efficiency and meet both current needs and future demands. In sum, high pressure vertical pumps stand at the frontier of industrial fluid management. Their unique design, coupled with a commitment to excellence and innovation by manufacturers, ensures they remain indispensable tools across diverse sectors. Their ongoing development highlights the significance of integrating cutting-edge technology with practical applications, demonstrating an unwavering dedication to enhancing industrial pumping solutions around the world.

From an experiential perspective, high pressure vertical pumps are favored for their easy maintenance and long-term cost efficiency. Their vertical design inherently allows for fewer mechanical seals and bearings; components that are typically prone to wear during operations. Consequently, this translates to fewer breakdowns and reduced downtime, a critical consideration for industries where continuous operation is non-negotiable. High pressure vertical pumps are also remarkably versatile. They can handle a range of fluids, from clean water to more viscous materials, including chemically aggressive or abrasive liquids. This versatility is crucial for industries such as mining, where the ability to pump slurry or other challenging fluids can significantly impact productivity and operational costs. For niche applications, customization becomes necessary, and manufacturers rise to the challenge by offering a range of impeller designs and material choices. Customization ensures that the pump not only meets industry standards but also surpasses them, tackling specific challenges head-on with measurable success. By understanding these facets — performance, expertise in design, authoritative testing, trust through certification, and real-world experiences — businesses can make informed decisions when investing in high pressure vertical pumps. As a result, they can ensure that their operations maintain high levels of efficiency and meet both current needs and future demands. In sum, high pressure vertical pumps stand at the frontier of industrial fluid management. Their unique design, coupled with a commitment to excellence and innovation by manufacturers, ensures they remain indispensable tools across diverse sectors. Their ongoing development highlights the significance of integrating cutting-edge technology with practical applications, demonstrating an unwavering dedication to enhancing industrial pumping solutions around the world.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024