-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 02, 2025 03:41

Back to list

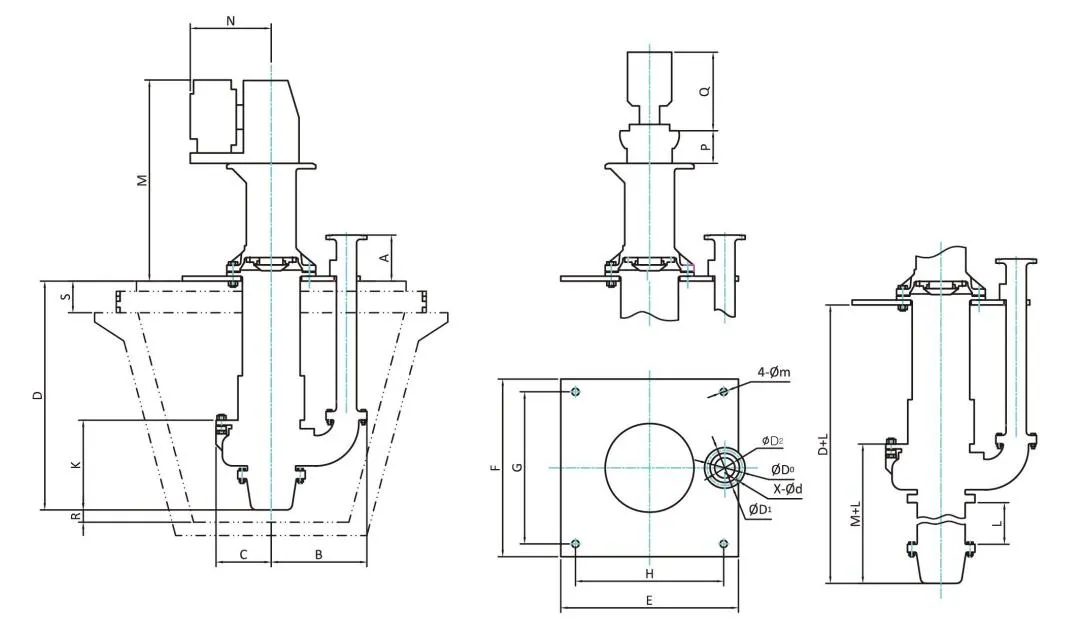

high pressure vertical centrifugal pump

High pressure vertical centrifugal pumps are indispensable components in a multitude of industrial applications, primarily due to their efficiency, reliability, and versatility. These pumps are particularly designed to handle fluids at high pressures, making them ideal for industries such as oil and gas, chemical processing, power generation, and water treatment. Understanding the intricacies of these pumps can significantly enhance their application and optimize performance within your systems.

Another significant aspect to consider is the energy consumption of these pumps, which directly impacts operational costs. Advances in pump technology have led to the development of energy-efficient models, incorporating variable frequency drives (VFDs) and high-efficiency impeller designs. These innovations allow for the fine-tuning of pump operation, adjusting the flow and pressure as required by the system, thus optimizing energy consumption and reducing costs significantly. In terms of trustworthiness, brands that manufacture high pressure vertical centrifugal pumps often carry substantial reputations upheld by years of expertise and proven track records. For anyone seeking to invest in these pumps, it is advisable to choose manufacturers who offer strong warranties and robust after-sales support, as these are indicators of confidence in their product’s performance and durability. Installation and maintenance of high pressure vertical centrifugal pumps should not be overlooked. Proper installation by trained professionals ensures that the pump operates at peak efficiency and reduces potential failures. Regular maintenance routines, including inspection of seals, bearings, and impeller condition, are vital for ensuring uninterrupted operation and longevity of the pump. Many companies provide detailed maintenance guides and have certified technicians available, which enhances the credibility and trust in their product offerings. The application of these pumps can be seen in innovative settings like renewable energy sectors where they aid in processes such as geothermal heating, showcasing their versatility beyond traditional industrial use. Here, their ability to manage high-pressure fluids efficiently contributes significantly to sustainable energy solutions. In conclusion, high pressure vertical centrifugal pumps stand as a testament to engineering ingenuity that marries functionality with efficiency. Their selection and integration into industrial systems should be approached with a comprehensive understanding of their mechanics, materials, and energy dynamics. By doing so, businesses can leverage the full potential of these pumps, achieving operational excellence and cost-effectiveness while relying on the expertise and authority of seasoned manufacturers and engineers.

Another significant aspect to consider is the energy consumption of these pumps, which directly impacts operational costs. Advances in pump technology have led to the development of energy-efficient models, incorporating variable frequency drives (VFDs) and high-efficiency impeller designs. These innovations allow for the fine-tuning of pump operation, adjusting the flow and pressure as required by the system, thus optimizing energy consumption and reducing costs significantly. In terms of trustworthiness, brands that manufacture high pressure vertical centrifugal pumps often carry substantial reputations upheld by years of expertise and proven track records. For anyone seeking to invest in these pumps, it is advisable to choose manufacturers who offer strong warranties and robust after-sales support, as these are indicators of confidence in their product’s performance and durability. Installation and maintenance of high pressure vertical centrifugal pumps should not be overlooked. Proper installation by trained professionals ensures that the pump operates at peak efficiency and reduces potential failures. Regular maintenance routines, including inspection of seals, bearings, and impeller condition, are vital for ensuring uninterrupted operation and longevity of the pump. Many companies provide detailed maintenance guides and have certified technicians available, which enhances the credibility and trust in their product offerings. The application of these pumps can be seen in innovative settings like renewable energy sectors where they aid in processes such as geothermal heating, showcasing their versatility beyond traditional industrial use. Here, their ability to manage high-pressure fluids efficiently contributes significantly to sustainable energy solutions. In conclusion, high pressure vertical centrifugal pumps stand as a testament to engineering ingenuity that marries functionality with efficiency. Their selection and integration into industrial systems should be approached with a comprehensive understanding of their mechanics, materials, and energy dynamics. By doing so, businesses can leverage the full potential of these pumps, achieving operational excellence and cost-effectiveness while relying on the expertise and authority of seasoned manufacturers and engineers.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024