-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 00:47

Back to list

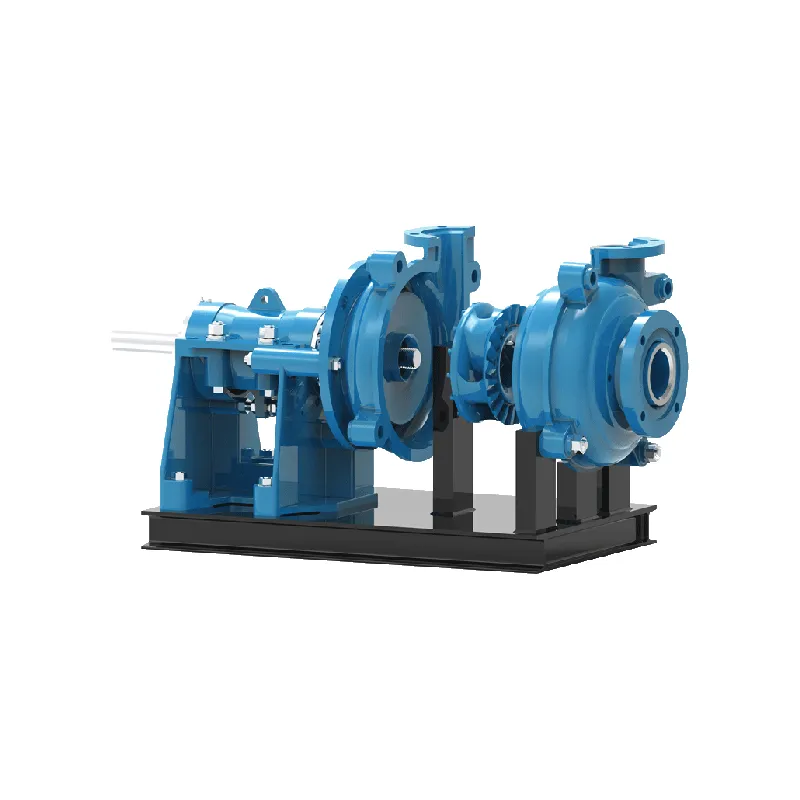

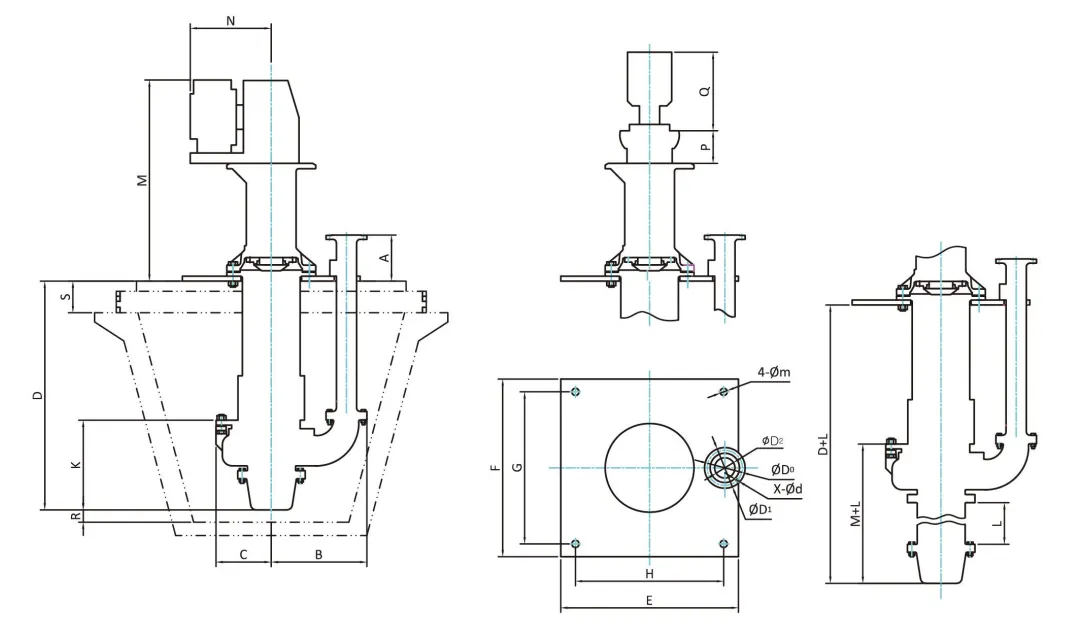

Horizontal Slurry Pumps MM6/4E-AHF

Navigating the complex world of high-pressure slurry pumps requires a blend of technical know-how and practical application, essential for industries ranging from mining to power generation. These robust machines are specifically engineered to handle abrasive and corrosive slurries under high pressure, making them indispensable in various heavy-duty operations. As an SEO-savvy content writer, integrating nuanced insights into the operational, structural, and material aspects of high-pressure slurry pumps can significantly enhance web presence and attract informed clientele.

Selection and implementation of the right pump require an authoritative understanding of the operational environment and the slurry's characteristics. Factors such as the slurry's particle size, concentration, and corrosiveness must be considered. It is advisable for engineers and procurement specialists to work closely with experienced manufacturers to customize pump design according to specific operational requirements. This collaborative approach ensures that the pump operates efficiently, with minimal downtime, and achieves optimal cost-effectiveness over its lifecycle. Trustworthy manufacturers provide not only high-quality pumps but also comprehensive after-sales services including installation assistance, routine maintenance, and emergency repair services. These services help in mitigating downtime and ensuring continuous operation. In addition, proper training for the operational staff on maintenance and safety can vastly improve the lifespan and performance of the pumps. Reliable manufacturers often offer training programs that cover everything from routine inspections to advanced troubleshooting techniques. The competitive landscape for high-pressure slurry pumps is continuously evolving with technological advancements. Innovations in sensor technology and remote monitoring systems have paved the way for smarter, more efficient pump management strategies. These technologies offer predictive maintenance capabilities, allowing operators to anticipate potential issues before they lead to costly breakdowns. Embracing such advancements not only improves pump reliability but also enhances the overall operational efficiency of industrial processes. In conclusion, successful integration and operation of high-pressure slurry pumps hinge on authoritative knowledge and trustworthy partnerships. With expertise in selecting the right materials, understanding structural intricacies, and implementing cutting-edge technologies, businesses can optimize their use of these essential pumps. Companies are encouraged to seek out experienced manufacturers who can provide not just pumps, but holistic solutions that meet specific industrial needs, ensuring longevity and performance excellence. By fostering a collaborative and informed approach, industries can effectively harness the power of high-pressure slurry pumps and maintain a competitive edge in their operations.

Selection and implementation of the right pump require an authoritative understanding of the operational environment and the slurry's characteristics. Factors such as the slurry's particle size, concentration, and corrosiveness must be considered. It is advisable for engineers and procurement specialists to work closely with experienced manufacturers to customize pump design according to specific operational requirements. This collaborative approach ensures that the pump operates efficiently, with minimal downtime, and achieves optimal cost-effectiveness over its lifecycle. Trustworthy manufacturers provide not only high-quality pumps but also comprehensive after-sales services including installation assistance, routine maintenance, and emergency repair services. These services help in mitigating downtime and ensuring continuous operation. In addition, proper training for the operational staff on maintenance and safety can vastly improve the lifespan and performance of the pumps. Reliable manufacturers often offer training programs that cover everything from routine inspections to advanced troubleshooting techniques. The competitive landscape for high-pressure slurry pumps is continuously evolving with technological advancements. Innovations in sensor technology and remote monitoring systems have paved the way for smarter, more efficient pump management strategies. These technologies offer predictive maintenance capabilities, allowing operators to anticipate potential issues before they lead to costly breakdowns. Embracing such advancements not only improves pump reliability but also enhances the overall operational efficiency of industrial processes. In conclusion, successful integration and operation of high-pressure slurry pumps hinge on authoritative knowledge and trustworthy partnerships. With expertise in selecting the right materials, understanding structural intricacies, and implementing cutting-edge technologies, businesses can optimize their use of these essential pumps. Companies are encouraged to seek out experienced manufacturers who can provide not just pumps, but holistic solutions that meet specific industrial needs, ensuring longevity and performance excellence. By fostering a collaborative and informed approach, industries can effectively harness the power of high-pressure slurry pumps and maintain a competitive edge in their operations.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024