-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 19, 2025 01:33

Back to list

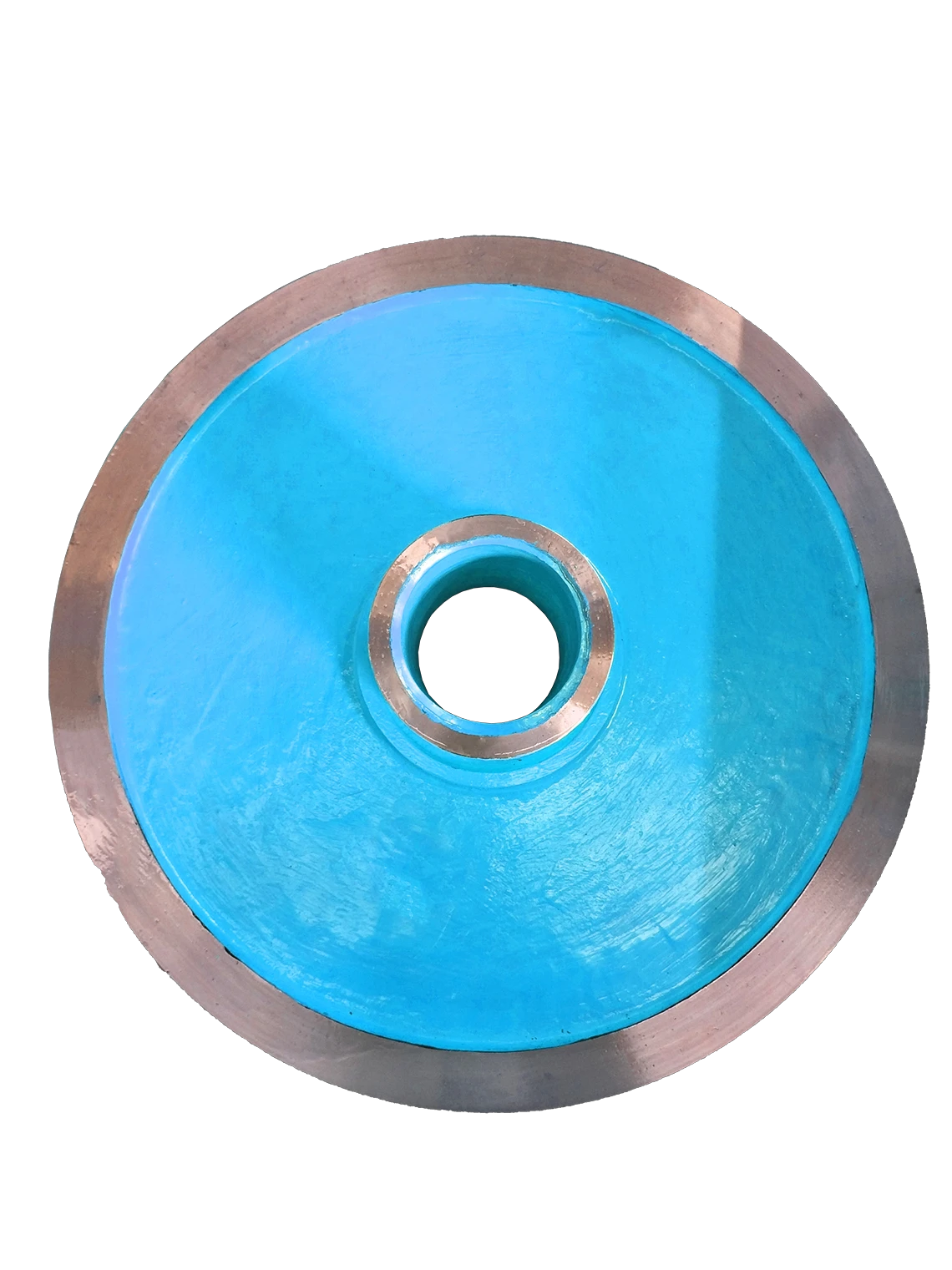

high pressure slurry pump

Choosing the right high pressure slurry pump can dramatically impact the performance and efficiency of industrial operations that depend on these robust machines. Understanding their vital role in industries like mining, wastewater management, and chemical processing is essential for selecting the best product suited to your needs. Here's an in-depth exploration of high pressure slurry pumps, emphasizing their features, optimal usage, and distinctive benefits.

Moreover, modern high-pressure slurry pumps feature advancements such as adjustable impeller clearance, which allows users to maintain peak performance without complete disassembly, thus reducing maintenance times. Automation controls and real-time monitoring have also become integral, offering precision that guards against unexpected failures and promotes timely maintenance. While the initial investment for high pressure slurry pumps might be considerable compared to conventional pumps, the total cost of ownership often reveals an altogether different picture. Businesses that employ these pumps find significant reductions in operational costs through less frequent maintenance and better energy usage — a testament to their economic efficiency. This makes a compelling case for stakeholders weighing long-term benefits against upfront expenditure. Another consideration is the environmental impact of using high-quality slurry pumps. The robust design and efficient functioning of these pumps ensure that energy consumption is kept to a minimum, thereby reducing the carbon footprint associated with industrial operations. This aspect resonates with industries committed to sustainable practices and compliance with ever-stringent environmental regulations. When selecting a high-pressure slurry pump, it's crucial to partner with reputable manufacturers and suppliers. Established brands often offer a wealth of expertise, providing guidance on pump selection specifically tailored to your operational needs. This ensures that the pump's materials, impellers, and other components are appropriately chosen to handle the specific types of slurry encountered in your industry. In conclusion, high pressure slurry pumps are an indispensable asset for industries requiring efficiency, durability, and reliability. Their advanced engineering, coupled with the ability to handle high-density solids, makes them a superior choice for operations where high-performance equipment is a must. By understanding the unique benefits and applications of these pumps, businesses can make informed investment decisions that enhance both productivity and profitability.

Moreover, modern high-pressure slurry pumps feature advancements such as adjustable impeller clearance, which allows users to maintain peak performance without complete disassembly, thus reducing maintenance times. Automation controls and real-time monitoring have also become integral, offering precision that guards against unexpected failures and promotes timely maintenance. While the initial investment for high pressure slurry pumps might be considerable compared to conventional pumps, the total cost of ownership often reveals an altogether different picture. Businesses that employ these pumps find significant reductions in operational costs through less frequent maintenance and better energy usage — a testament to their economic efficiency. This makes a compelling case for stakeholders weighing long-term benefits against upfront expenditure. Another consideration is the environmental impact of using high-quality slurry pumps. The robust design and efficient functioning of these pumps ensure that energy consumption is kept to a minimum, thereby reducing the carbon footprint associated with industrial operations. This aspect resonates with industries committed to sustainable practices and compliance with ever-stringent environmental regulations. When selecting a high-pressure slurry pump, it's crucial to partner with reputable manufacturers and suppliers. Established brands often offer a wealth of expertise, providing guidance on pump selection specifically tailored to your operational needs. This ensures that the pump's materials, impellers, and other components are appropriately chosen to handle the specific types of slurry encountered in your industry. In conclusion, high pressure slurry pumps are an indispensable asset for industries requiring efficiency, durability, and reliability. Their advanced engineering, coupled with the ability to handle high-density solids, makes them a superior choice for operations where high-performance equipment is a must. By understanding the unique benefits and applications of these pumps, businesses can make informed investment decisions that enhance both productivity and profitability.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024