-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 20, 2025 08:19

Back to list

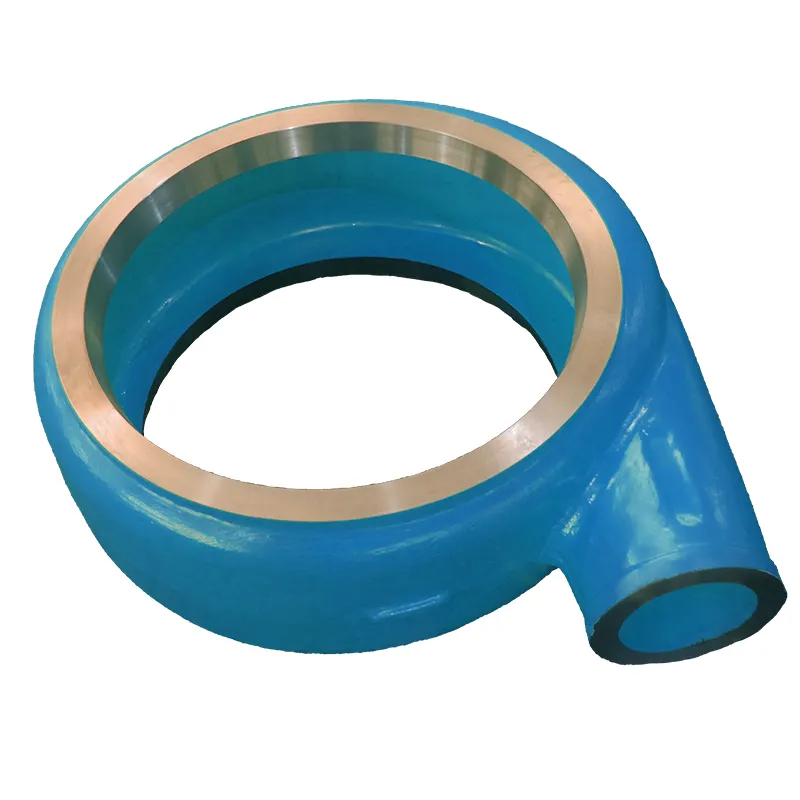

high density slurry pump

The efficacy and efficiency of high density slurry pumps cannot be overstated when considering industrial applications that demand robust material handling and fluid transfer. High-density slurry pumps are specifically engineered to handle abrasive, thick, and high-solid-content slurries that other types of pumps struggle with. Various industries globally, ranging from mining to wastewater treatment, rely on these pumps for their operational dependability and superior performance.

Authoritativeness in the field is evident as leading industry standards and certifications back these slurry pumps. Renowned manufacturers of high-density slurry pumps comply with stringent quality controls and international standards such as ISO and ANSI regulations. These certifications provide assurance to businesses that they are investing in reliable technology supported by years of proven performance and adherence to quality benchmarks. Trustworthiness stems from the consistent feedback from industry professionals who utilize high-density slurry pumps in their operations. By prioritizing durability, efficiency, and versatility, these pumps have built a strong reputation for reliability. Manufacturers often offer extensive customer support and after-sales service to further enhance user confidence. This includes detailed product documentation, easy access to replacement parts, and responsive service teams, all contributing to long-term trust in the product and brand. To sum up, the competitive edge of high-density slurry pumps lies in their exceptional handling of viscous, abrasive materials, and their ability to deliver sustained performance in demanding industrial environments. These pumps embody advanced engineering principles, supported by rigorous testing and continuous innovations to meet evolving industrial needs. The result is a durable, efficient, and reliable solution that industries can rely on for optimal productivity and cost savings.

Authoritativeness in the field is evident as leading industry standards and certifications back these slurry pumps. Renowned manufacturers of high-density slurry pumps comply with stringent quality controls and international standards such as ISO and ANSI regulations. These certifications provide assurance to businesses that they are investing in reliable technology supported by years of proven performance and adherence to quality benchmarks. Trustworthiness stems from the consistent feedback from industry professionals who utilize high-density slurry pumps in their operations. By prioritizing durability, efficiency, and versatility, these pumps have built a strong reputation for reliability. Manufacturers often offer extensive customer support and after-sales service to further enhance user confidence. This includes detailed product documentation, easy access to replacement parts, and responsive service teams, all contributing to long-term trust in the product and brand. To sum up, the competitive edge of high-density slurry pumps lies in their exceptional handling of viscous, abrasive materials, and their ability to deliver sustained performance in demanding industrial environments. These pumps embody advanced engineering principles, supported by rigorous testing and continuous innovations to meet evolving industrial needs. The result is a durable, efficient, and reliable solution that industries can rely on for optimal productivity and cost savings.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024