-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 17, 2025 03:50

Back to list

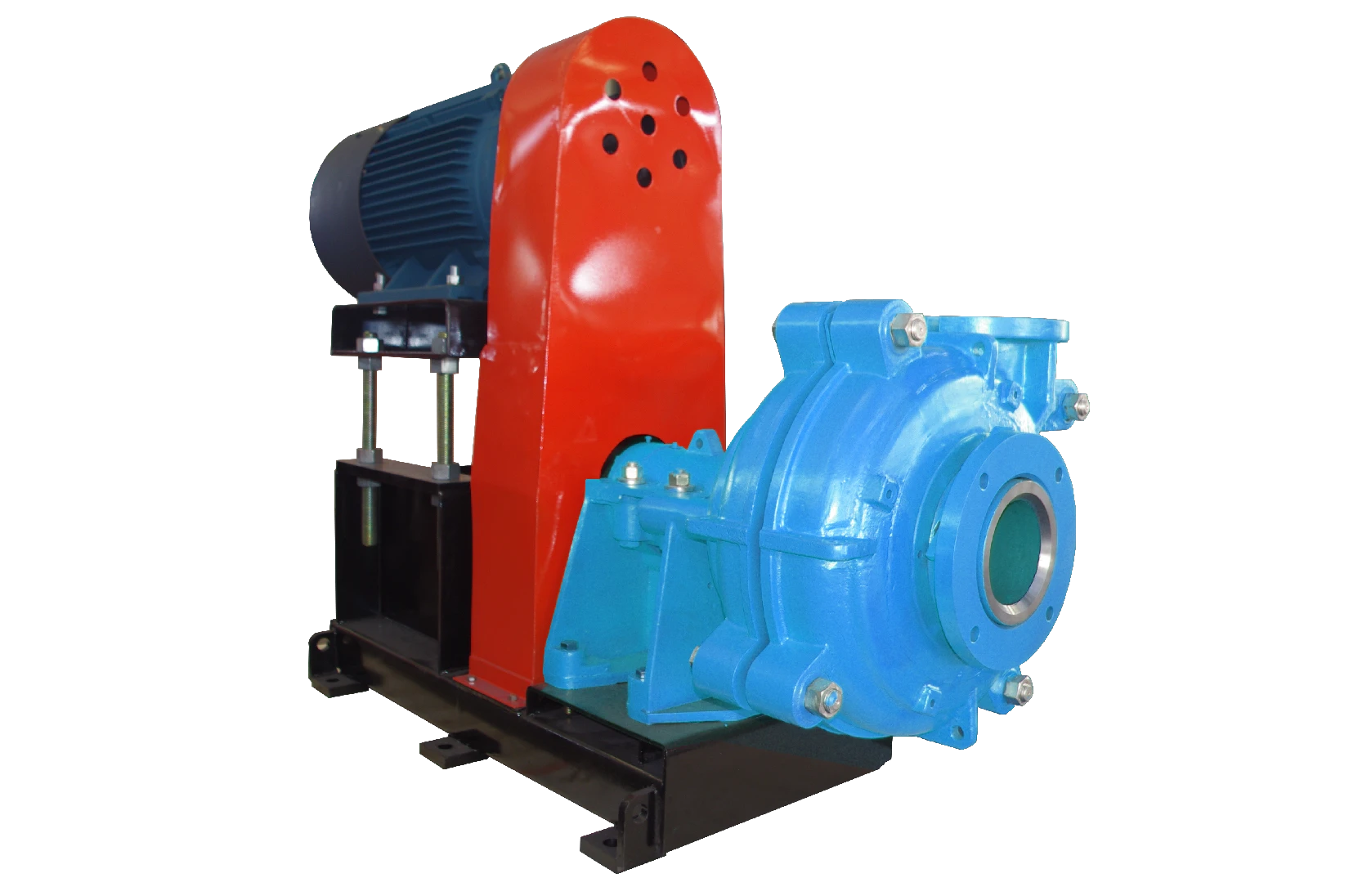

heavy duty slurry pumps

Heavy duty slurry pumps are pivotal in industries such as mining, dredging, and waste management, where they are tasked with transporting a mixture of liquid and solid particles. These robust engineering marvels are designed to handle highly abrasive and corrosive slurries that conventional pumps cannot process. Their operational efficiency and durability directly impact the productivity and cost-effectiveness of industrial operations. Let’s delve into the experience, expertise, authoritativeness, and trustworthiness that highlight the significance of heavy duty slurry pumps in these sectors.

Authoritativeness in the domain of heavy duty slurry pumps comes from an established track record and recognition by peers in the field. Companies specializing in slurry pump manufacturing often employ a collaborative approach, working with end-users to tailor solutions based on real-world challenges. This collaboration fosters innovations that are both practical and effective. Industry bodies and standards, such as those provided by the Hydraulic Institute or the American National Standards Institute, act as trusted benchmarks, ensuring that pumps meet rigorous performance and safety criteria, thus adding a layer of security and reliability for users. Trustworthiness goes beyond compliance and performance; it encapsulates the brand’s commitment to quality, safety, and customer satisfaction. Leading brands have established their reputations through consistent delivery of reliable products, supported by warranties, and comprehensive after-sales service. Training programs and on-site technical support further reinforce trust by empowering users to operate their equipment at optimal capacity with minimal risk of downtime. Heavy duty slurry pumps remain an integral component of multiple industrial applications. Their relevance and necessity are perpetually underscored by the ever-growing demand for efficient material handling solutions in challenging environments. As technologies evolve, the industry is poised to witness even more refined solutions, incorporating cutting-edge materials and intelligent systems that promise greater efficiency and sustainability. In conclusion, the lifecycle and performance of heavy duty slurry pumps are tied to an intricate blend of practical experience, engineering expertise, authoritative standards, and trustworthy practices. The symbiotic relationship between manufacturers and end-users drives innovations that optimize functionality and reliability, ultimately shaping the future of industries reliant upon these heavy-duty machines.

Authoritativeness in the domain of heavy duty slurry pumps comes from an established track record and recognition by peers in the field. Companies specializing in slurry pump manufacturing often employ a collaborative approach, working with end-users to tailor solutions based on real-world challenges. This collaboration fosters innovations that are both practical and effective. Industry bodies and standards, such as those provided by the Hydraulic Institute or the American National Standards Institute, act as trusted benchmarks, ensuring that pumps meet rigorous performance and safety criteria, thus adding a layer of security and reliability for users. Trustworthiness goes beyond compliance and performance; it encapsulates the brand’s commitment to quality, safety, and customer satisfaction. Leading brands have established their reputations through consistent delivery of reliable products, supported by warranties, and comprehensive after-sales service. Training programs and on-site technical support further reinforce trust by empowering users to operate their equipment at optimal capacity with minimal risk of downtime. Heavy duty slurry pumps remain an integral component of multiple industrial applications. Their relevance and necessity are perpetually underscored by the ever-growing demand for efficient material handling solutions in challenging environments. As technologies evolve, the industry is poised to witness even more refined solutions, incorporating cutting-edge materials and intelligent systems that promise greater efficiency and sustainability. In conclusion, the lifecycle and performance of heavy duty slurry pumps are tied to an intricate blend of practical experience, engineering expertise, authoritative standards, and trustworthy practices. The symbiotic relationship between manufacturers and end-users drives innovations that optimize functionality and reliability, ultimately shaping the future of industries reliant upon these heavy-duty machines.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024