-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 17, 2025 05:44

Back to list

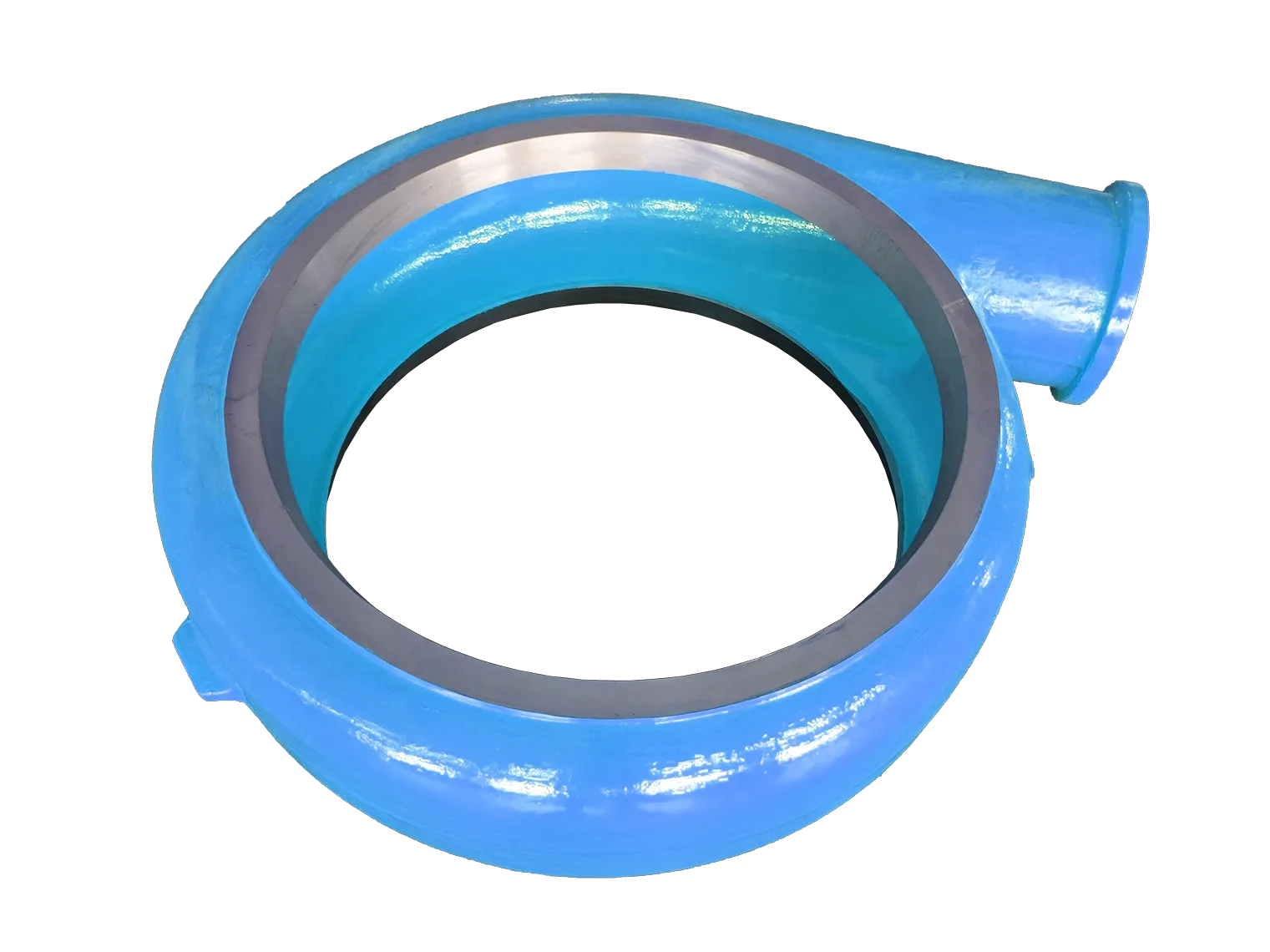

heavy duty slurry pump

When it comes to industrial equipment that can endure the harshest environments and deliver robust performance, few machines match the reliability and efficiency of heavy-duty slurry pumps. These pumps are essential in numerous industries, offering unparalleled durability and operational excellence.

Moreover, technological innovations have introduced smart features to contemporary slurry pumps. These advancements include real-time monitoring systems that track the pump's performance metrics, alerting operators to any anomalies before they lead to failure. This incorporation of IoT (Internet of Things) technology represents a significant leap in authoritativeness and trust, as it allows businesses to make data-driven decisions that extend the life of their equipment and optimize its operation. Reliability is a non-negotiable characteristic of slurry pumps, and trustworthiness stems from rigorous testing and quality control processes. Manufacturers that boast a strong reputation often subject their pumps to exhaustive trials that simulate real-world conditions, ensuring that each unit can withstand extreme pressures and temperatures. This testing phase is crucial because it assures clients that their investment in heavy-duty slurry pumps is backed by concrete evidence of durability and efficiency. Furthermore, the manufacturer's commitment to customer support greatly influences the pump’s perceived trustworthiness. Companies renowned for their heavy-duty slurry pumps offer comprehensive after-sales services, including training, maintenance, and readily available spare parts. This holistic approach ensures that operators are never stranded without support, ultimately building long-term trust with their clientele. In conclusion, heavy-duty slurry pumps symbolize the pinnacle of engineering prowess in handling complex and abrasive materials. Their continued evolution through smarter technology, advanced materials, and expert design underscores their irreplaceable role in various industrial operations. By focusing on experience, expertise, authoritativeness, and trustworthiness, heavy-duty slurry pumps establish themselves as indispensable assets, fulfilling their role with unmatched reliability and efficiency.

Moreover, technological innovations have introduced smart features to contemporary slurry pumps. These advancements include real-time monitoring systems that track the pump's performance metrics, alerting operators to any anomalies before they lead to failure. This incorporation of IoT (Internet of Things) technology represents a significant leap in authoritativeness and trust, as it allows businesses to make data-driven decisions that extend the life of their equipment and optimize its operation. Reliability is a non-negotiable characteristic of slurry pumps, and trustworthiness stems from rigorous testing and quality control processes. Manufacturers that boast a strong reputation often subject their pumps to exhaustive trials that simulate real-world conditions, ensuring that each unit can withstand extreme pressures and temperatures. This testing phase is crucial because it assures clients that their investment in heavy-duty slurry pumps is backed by concrete evidence of durability and efficiency. Furthermore, the manufacturer's commitment to customer support greatly influences the pump’s perceived trustworthiness. Companies renowned for their heavy-duty slurry pumps offer comprehensive after-sales services, including training, maintenance, and readily available spare parts. This holistic approach ensures that operators are never stranded without support, ultimately building long-term trust with their clientele. In conclusion, heavy-duty slurry pumps symbolize the pinnacle of engineering prowess in handling complex and abrasive materials. Their continued evolution through smarter technology, advanced materials, and expert design underscores their irreplaceable role in various industrial operations. By focusing on experience, expertise, authoritativeness, and trustworthiness, heavy-duty slurry pumps establish themselves as indispensable assets, fulfilling their role with unmatched reliability and efficiency.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024