-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 08, 2025 04:54

Back to list

function of wear ring in centrifugal pump

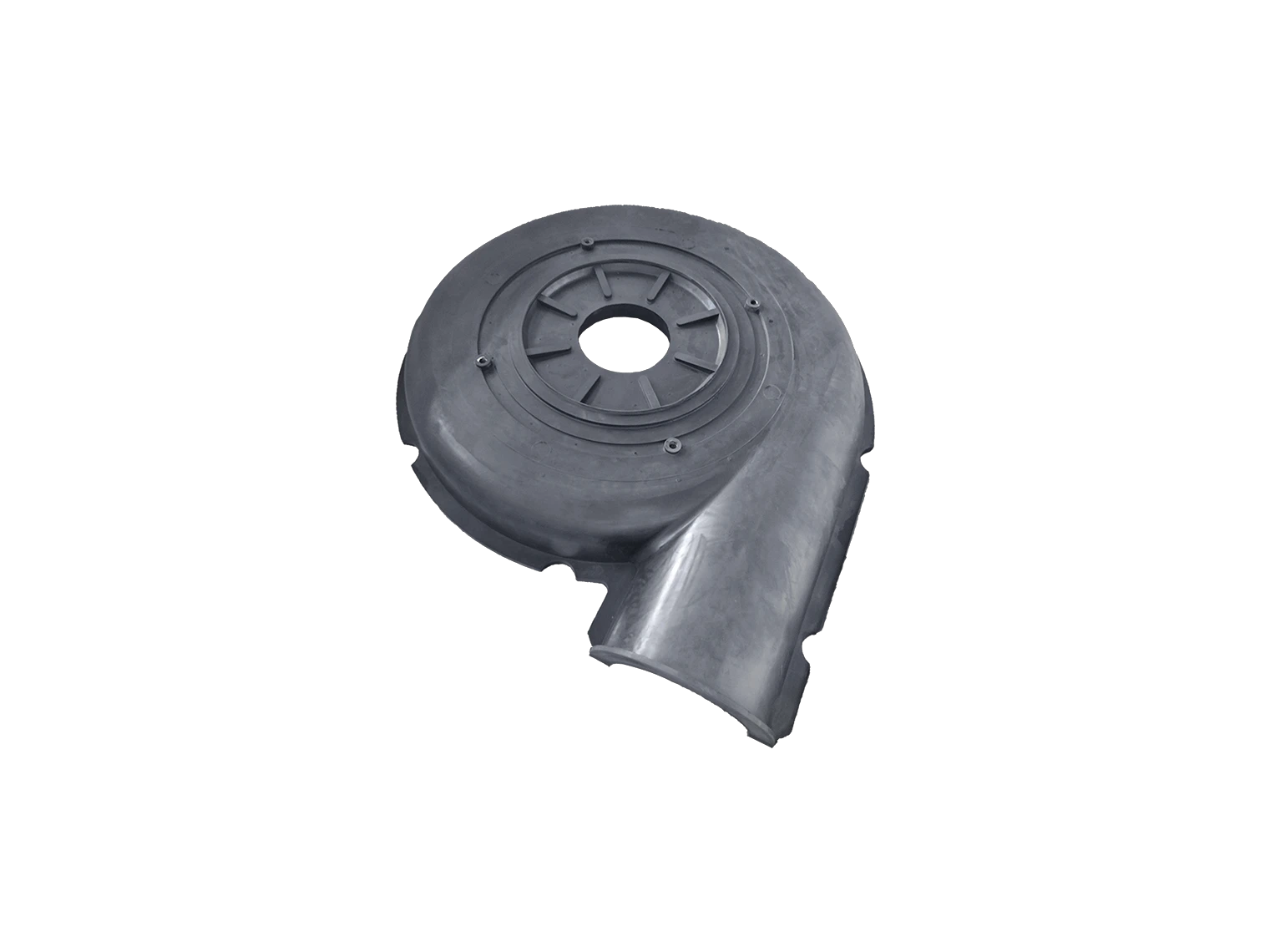

The wear ring in a centrifugal pump is a crucial yet often overlooked component responsible for maintaining pump efficiency and prolonging its operational life. Located between the impeller and the casing, the wear ring minimizes the clearance leakage between these parts, thus ensuring optimal pump performance. A deeper understanding of its functionality not only highlights its significance but also underscores its role in reducing maintenance costs and enhancing pump reliability.

Regular inspection and timely replacement of the wear ring are vital to the centrifugal pump’s health. Over time, wear rings erode, resulting in increased clearance between the impeller and the casing. This erosion leads to higher leakage rates, reduced efficiency, and increased operational costs. Therefore, a systematic maintenance schedule that includes monitoring the clearance size and general condition of wear rings should be a standard practice in facilities utilizing centrifugal pumps. Implementing such preventive measures not only curtails unexpected downtimes but also extends the operational lifespan of the pump. Moreover, selecting the appropriate design and material for a wear ring should align with the specific application demands. For example, in environments where corrosive liquids are pumped, corrosion-resistant materials for wear rings are not just beneficial but necessary. Similarly, in abrasive environments, choosing wear rings made from harder materials will minimize degradation. Such strategic decision-making draws upon thorough expertise in material sciences and a comprehensive understanding of pumping systems, factors paramount to maximizing the wear ring’s utility. Establishing stringent guidelines and standards for wear ring usage and maintenance is also crucial in promoting trust and building credibility with stakeholders involved in industrial operations. Expertise-driven strategies, including adopting innovative coating technologies to enhance wear resistance, demonstrate a forward-thinking approach to pump management. As recognized best practices evolve, staying abreast of technological advancements and incorporating empirical data into maintenance regimens fosters a culture of reliability and efficiency. In sum, the wear ring is not merely a passive component of the centrifugal pump but rather a dynamic element contributing to its effective functioning. Its role in minimizing internal leakage, conserving energy, and safeguarding more expensive parts underscores its importance in pump design and maintenance. Insightful understanding and proactive management of wear rings epitomize the blend of engineering expertise and operational excellence — qualities that drive enduring performance and scalability in centrifugal pumping systems.

Regular inspection and timely replacement of the wear ring are vital to the centrifugal pump’s health. Over time, wear rings erode, resulting in increased clearance between the impeller and the casing. This erosion leads to higher leakage rates, reduced efficiency, and increased operational costs. Therefore, a systematic maintenance schedule that includes monitoring the clearance size and general condition of wear rings should be a standard practice in facilities utilizing centrifugal pumps. Implementing such preventive measures not only curtails unexpected downtimes but also extends the operational lifespan of the pump. Moreover, selecting the appropriate design and material for a wear ring should align with the specific application demands. For example, in environments where corrosive liquids are pumped, corrosion-resistant materials for wear rings are not just beneficial but necessary. Similarly, in abrasive environments, choosing wear rings made from harder materials will minimize degradation. Such strategic decision-making draws upon thorough expertise in material sciences and a comprehensive understanding of pumping systems, factors paramount to maximizing the wear ring’s utility. Establishing stringent guidelines and standards for wear ring usage and maintenance is also crucial in promoting trust and building credibility with stakeholders involved in industrial operations. Expertise-driven strategies, including adopting innovative coating technologies to enhance wear resistance, demonstrate a forward-thinking approach to pump management. As recognized best practices evolve, staying abreast of technological advancements and incorporating empirical data into maintenance regimens fosters a culture of reliability and efficiency. In sum, the wear ring is not merely a passive component of the centrifugal pump but rather a dynamic element contributing to its effective functioning. Its role in minimizing internal leakage, conserving energy, and safeguarding more expensive parts underscores its importance in pump design and maintenance. Insightful understanding and proactive management of wear rings epitomize the blend of engineering expertise and operational excellence — qualities that drive enduring performance and scalability in centrifugal pumping systems.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024