-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

function of impeller in centrifugal pump

The Function of the Impeller in a Centrifugal Pump

Centrifugal pumps play a crucial role in a variety of industries, from water treatment facilities to petroleum refineries, by efficiently transporting fluids. At the heart of these pumps lies the impeller, a key component that significantly influences the pump's performance. Understanding the function of the impeller is essential for engineers and operators to optimize efficiency and maintain operational reliability.

The primary function of the impeller in a centrifugal pump is to transfer mechanical energy from the motor to the fluid, converting it into kinetic energy. This process begins when the motor drives the impeller, which consists of a rotating disk with vanes. As the impeller rotates, the vanes propel the fluid outward from the center of the impeller due to centrifugal force. This action creates a low-pressure zone at the impeller's eye (the center), allowing fluid to enter the impeller continuously.

The design of the impeller greatly impacts the pump's efficiency and performance. Impellers can be classified into various types, including open, closed, and semi-closed designs, each suited for different applications. Closed impellers, for instance, are often used for transferring clean fluids as they provide higher efficiency and better hydraulic performance. In contrast, open impellers are preferred in applications involving slurries or fluids with particulates due to their ability to handle larger particles without clogging.

function of impeller in centrifugal pump

The rotational speed of the impeller also plays a vital role in determining the pump’s flow rate and pressure generation. Higher rotational speeds lead to increase fluid velocity, which can result in higher pressure output. However, pumping fluids at excessively high speeds can cause issues such as cavitation, where vapor bubbles form and collapse within the pump, potentially damaging components and reducing lifespan.

Another key aspect of the impeller's function is its influence on the pump's head, which is the height (or pressure) to which the pump can raise the fluid. The impeller geometry, including its diameter and the angle of the vanes, directly affects this head. Engineers must carefully select or design the impeller to ensure that it meets the specific requirements of the application, such as the desired flow rate and system pressure.

Moreover, maintaining the impeller's condition is essential for the reliability of the centrifugal pump. Regular inspections can identify wear or damage, which can affect the efficiency and performance of the pump. Replacement of worn impellers or the entire pump assembly may be necessary to prevent costly breakdowns or inefficient operation.

In conclusion, the impeller is a vital component of the centrifugal pump, responsible for converting mechanical energy into kinetic energy to move fluids efficiently. Its design, rotational speed, and maintenance directly influence the pump's performance, making it essential for engineers and operators to understand its critical role in fluid transport systems.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

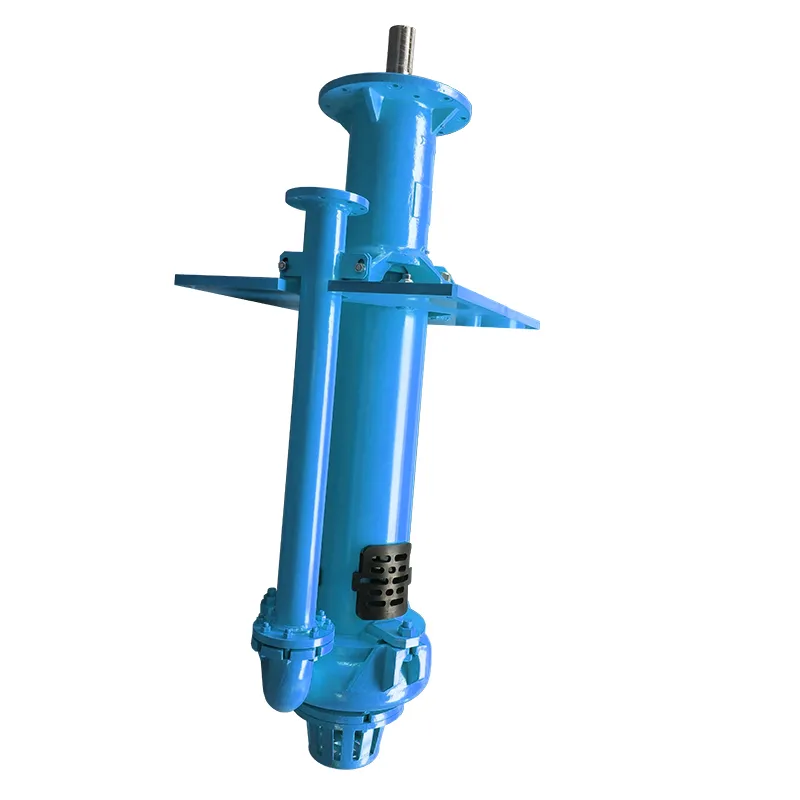

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024