-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 10, 2025 21:32

Back to list

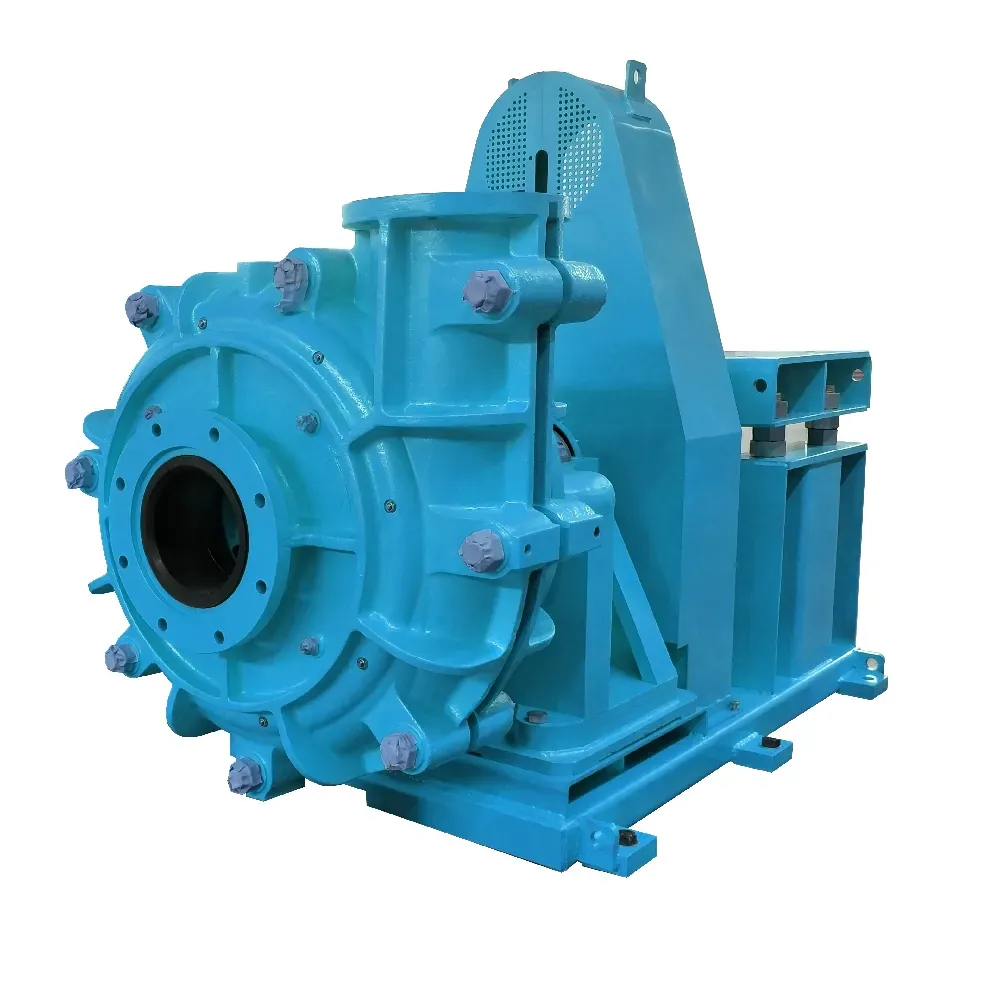

Pump Wear Parts DH2110 Metal

In the complex landscape of industrial machinery, selecting the right components is crucial for ensuring longevity, efficiency, and optimal performance. The frame plate liner insert, a seemingly humble component, plays a pivotal role in various applications, including pumps, compressors, and other heavy-duty equipment. Understanding its functionality, material composition, and the benefits it brings to industrial operations is vital for engineers and procurement professionals looking to enhance their systems.

Authoritative voices in mechanical engineering advocate for a systematic approach to the monitoring and maintenance of frame plate liner inserts. Implementing a predictive maintenance system can help detect signs of wear early, preventing potential operational disruptions. Engineers utilize advanced techniques such as ultrasonic testing and thermal imaging to assess the condition of these inserts, tapping into technological advancements that promote better safety standards and operational practices. Trustworthiness in selecting suppliers for frame plate liner inserts is another pivotal element. Collaborating with reputable manufacturers who adhere to stringent quality standards ensures that these components meet the necessary specifications and performance criteria. Reliable suppliers offer comprehensive documentation and certifications that provide peace of mind, assuring stakeholders about product authenticity and quality. In conclusion, frame plate liner inserts are indispensable in the sphere of industrial machinery—integral to both performance efficiency and cost management. By appreciating their role, selecting the right materials, ensuring correct installation, monitoring their performance, and choosing trustworthy suppliers, businesses can maximize their machinery's operational lifespan and overall productivity. The insights provided by this holistic approach underscore the significance of frame plate liner inserts, illustrating how their strategic application can transform industrial operations, setting benchmarks for modern engineering excellence and innovation.

Authoritative voices in mechanical engineering advocate for a systematic approach to the monitoring and maintenance of frame plate liner inserts. Implementing a predictive maintenance system can help detect signs of wear early, preventing potential operational disruptions. Engineers utilize advanced techniques such as ultrasonic testing and thermal imaging to assess the condition of these inserts, tapping into technological advancements that promote better safety standards and operational practices. Trustworthiness in selecting suppliers for frame plate liner inserts is another pivotal element. Collaborating with reputable manufacturers who adhere to stringent quality standards ensures that these components meet the necessary specifications and performance criteria. Reliable suppliers offer comprehensive documentation and certifications that provide peace of mind, assuring stakeholders about product authenticity and quality. In conclusion, frame plate liner inserts are indispensable in the sphere of industrial machinery—integral to both performance efficiency and cost management. By appreciating their role, selecting the right materials, ensuring correct installation, monitoring their performance, and choosing trustworthy suppliers, businesses can maximize their machinery's operational lifespan and overall productivity. The insights provided by this holistic approach underscore the significance of frame plate liner inserts, illustrating how their strategic application can transform industrial operations, setting benchmarks for modern engineering excellence and innovation.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024