-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 20, 2025 13:55

Back to list

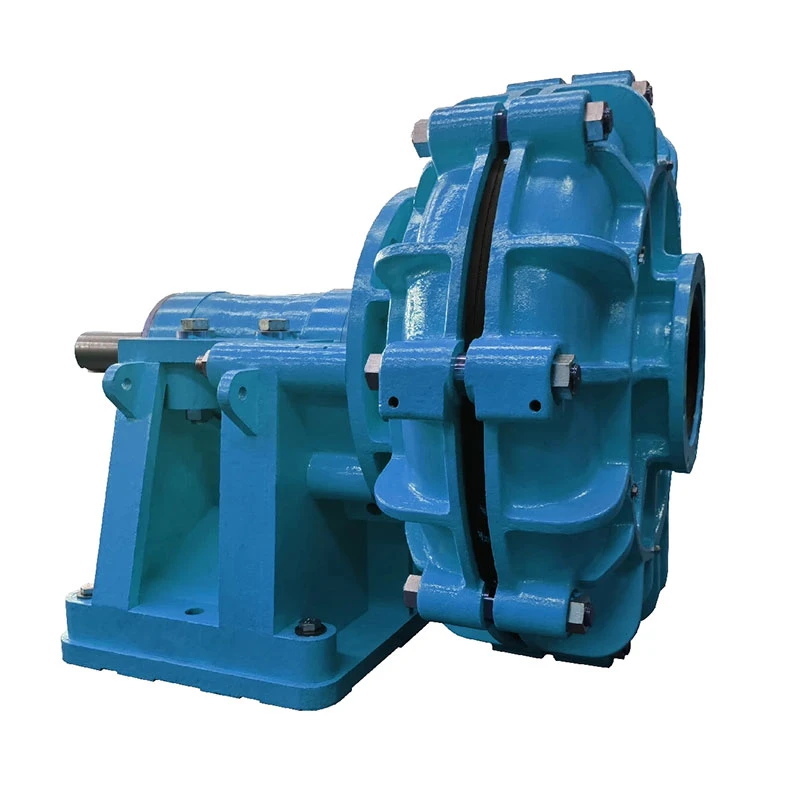

engine driven slurry pump

Harnessing the potential of an engine driven slurry pump can revolutionize processes in industries ranging from mining to waste management. These powerful tools are fundamental for moving mixtures of solid particles and liquids, efficiently addressing challenges posed by abrasive and corrosive slurries. The essence of choosing the right engine driven slurry pump lies not just in its mechanical construction but also in understanding the intricate details of its function, ensuring that solutions are both practical and sustainable.

Authoritativeness in slurry pump technology is often represented by industry standards and compliance benchmarks, such as those set by the Hydraulic Institute or ISO certifications. Engine driven slurry pumps that adhere to these standards not only guarantee safety and reliability but also cement their reputation in the marketplace. Manufacturers who are at the forefront of innovation tend to lead by example, setting new norms in the industry through continuous research and development. They collaborate with leading research bodies and institutions, driving technological progress. This leadership is not just about building a quality product; it involves educating the industry on sustainable practices and efficiency improvements. Trust is paramount when dealing with heavy-duty equipment like engine driven slurry pumps. Ensuring trustworthiness extends beyond the product itself. It encompasses after-sale service, warranty, technical support, and customer education. Companies that provide transparent product data, easy access to service records, and a network of expert technicians build lasting relationships with their clients. Customer reviews and testimonials play a significant role in establishing trust; they are a reflection of the product’s performance and the company’s commitment to its users. Reliable manufacturers invest in creating detailed guides and offer training sessions to guarantee that operators are well-versed in the pump’s functionalities, thus reducing operational risks. The choice of an engine driven slurry pump should never be taken lightly. It involves balancing numerous factors including cost, operational efficiency, environmental impact, and maintenance requirements. However, with the right knowledge and strategic planning, these pumps can dramatically improve productivity and profitability. By focusing on real-world experience, technical expertise, authoritative standards, and building trust, businesses can confidently navigate the complexities of slurry transportation. This holistic approach ensures not only the optimal performance of the pump but also the long-term success of the operations it supports.

Authoritativeness in slurry pump technology is often represented by industry standards and compliance benchmarks, such as those set by the Hydraulic Institute or ISO certifications. Engine driven slurry pumps that adhere to these standards not only guarantee safety and reliability but also cement their reputation in the marketplace. Manufacturers who are at the forefront of innovation tend to lead by example, setting new norms in the industry through continuous research and development. They collaborate with leading research bodies and institutions, driving technological progress. This leadership is not just about building a quality product; it involves educating the industry on sustainable practices and efficiency improvements. Trust is paramount when dealing with heavy-duty equipment like engine driven slurry pumps. Ensuring trustworthiness extends beyond the product itself. It encompasses after-sale service, warranty, technical support, and customer education. Companies that provide transparent product data, easy access to service records, and a network of expert technicians build lasting relationships with their clients. Customer reviews and testimonials play a significant role in establishing trust; they are a reflection of the product’s performance and the company’s commitment to its users. Reliable manufacturers invest in creating detailed guides and offer training sessions to guarantee that operators are well-versed in the pump’s functionalities, thus reducing operational risks. The choice of an engine driven slurry pump should never be taken lightly. It involves balancing numerous factors including cost, operational efficiency, environmental impact, and maintenance requirements. However, with the right knowledge and strategic planning, these pumps can dramatically improve productivity and profitability. By focusing on real-world experience, technical expertise, authoritative standards, and building trust, businesses can confidently navigate the complexities of slurry transportation. This holistic approach ensures not only the optimal performance of the pump but also the long-term success of the operations it supports.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024