-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 17, 2025 04:58

Back to list

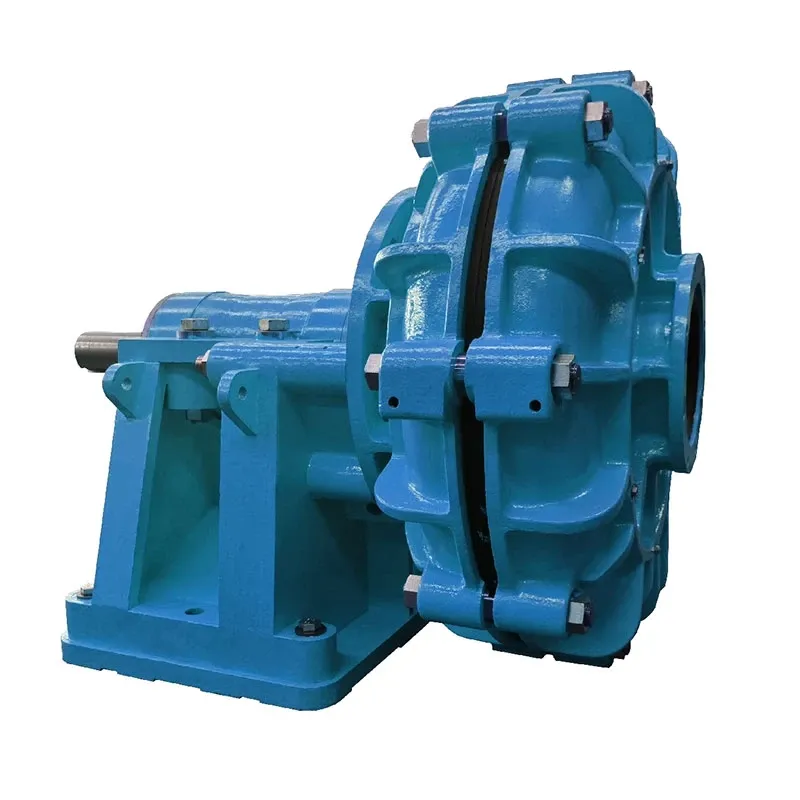

electric slurry pump

Navigating the market of electric slurry pumps can be overwhelming, especially with the myriad of models and specifications that promise unmatched performance. As industries advance, the demand for high-quality, efficient, and reliable equipment like electric slurry pumps surges. Rooted in years of expertise, this article aims to demystify these pumps, offering insights and recommendations based on real-world applications.

Operational downtime can severely impact productivity and profitability, making maintenance considerations paramount. The best electric slurry pumps are designed with user-friendly maintenance features, often incorporating modular designs that allow for quick and easy replacement of worn parts. Feedback from maintenance engineers often emphasizes identifying pumps with easily accessible components and clear maintenance manuals to minimize disruption. Incorporating a trusted electric slurry pump into your operations necessitates a partnership with reputable manufacturers renowned for their engineering acumen and product guarantees. Companies that back their products with solid warranties and responsive customer service invariably rank high in trustworthiness. Research and reviews attest that brands that provide comprehensive support, from installation to after-sales service, foster a sense of reliability and security among users. To conclude, the effective deployment of electric slurry pumps is not merely a matter of choosing the right equipment but involves a holistic understanding of operational needs, environmental considerations, and the long-term vision of an industry’s development goals. From this vantage point, deploying the right electric slurry pump becomes a strategic decision that reflects a commitment to excellence and sustainable operations. As markets evolve, staying updated on technological advancements and integrating them into your operations will ensure competitive advantage and operational success.

Operational downtime can severely impact productivity and profitability, making maintenance considerations paramount. The best electric slurry pumps are designed with user-friendly maintenance features, often incorporating modular designs that allow for quick and easy replacement of worn parts. Feedback from maintenance engineers often emphasizes identifying pumps with easily accessible components and clear maintenance manuals to minimize disruption. Incorporating a trusted electric slurry pump into your operations necessitates a partnership with reputable manufacturers renowned for their engineering acumen and product guarantees. Companies that back their products with solid warranties and responsive customer service invariably rank high in trustworthiness. Research and reviews attest that brands that provide comprehensive support, from installation to after-sales service, foster a sense of reliability and security among users. To conclude, the effective deployment of electric slurry pumps is not merely a matter of choosing the right equipment but involves a holistic understanding of operational needs, environmental considerations, and the long-term vision of an industry’s development goals. From this vantage point, deploying the right electric slurry pump becomes a strategic decision that reflects a commitment to excellence and sustainable operations. As markets evolve, staying updated on technological advancements and integrating them into your operations will ensure competitive advantage and operational success.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024