-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 11:07

Back to list

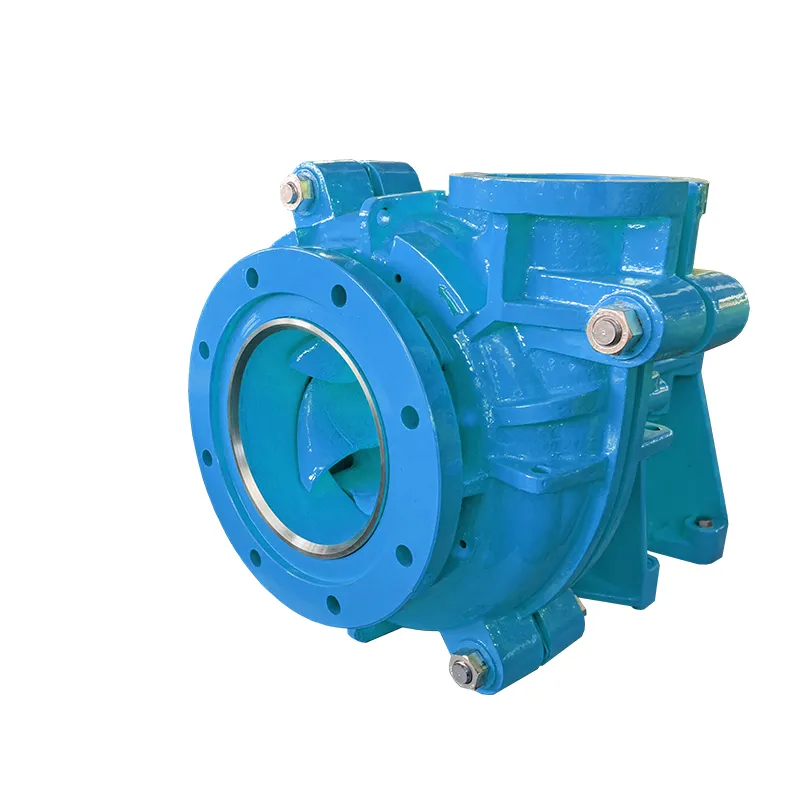

double volute centrifugal pump

The double volute centrifugal pump stands as a pinnacle of engineering design in the world of fluid dynamics, offering a myriad of benefits over traditional single volute systems. Its principal advantage lies in the significantly reduced radial load on the pump shaft, which directly translates to extended bearing life and increased reliability of the pump as a whole. This design evolution has successfully addressed the common issues of vibration and noise, ushering in a new era of efficient and quiet fluid transport systems.

Trustworthiness in double volute centrifugal pumps is further amplified by their proven track record in various demanding applications. Established manufacturers employ rigorous testing and quality assurance protocols to ensure each pump meets or exceeds industry standards. Materials used in construction are chosen for their durability and resistance to corrosion, a testimony to the pump’s ability to withstand prolonged exposure to aggressive and abrasive substances. In practical application, users have reported significant gains in both productivity and equipment longevity. Through firsthand experience, operators note the exceptional ease of maintenance attributed to the balanced design, which prevents unnecessary wear and tear. This user feedback underlines the pump’s capability to maintain long-term performance with minimal intervention, a critical factor for industries operating 24/7 with little margin for error. In conclusion, the double volute centrifugal pump represents a substantial leap forward in pump technology. Its design not only resolves the limitations of single volute systems but also presents a robust solution aligned with modern industry demands. For businesses prioritizing efficiency, reliability, and low operational costs, investing in double volute centrifugal pumps is a strategic decision supported by engineering expertise, authoritative performance data, and user trust. As industries continue to evolve, the role of these pumps as essential components in fluid handling systems is set to expand, ensuring their relevance and indispensability in the years to come.

Trustworthiness in double volute centrifugal pumps is further amplified by their proven track record in various demanding applications. Established manufacturers employ rigorous testing and quality assurance protocols to ensure each pump meets or exceeds industry standards. Materials used in construction are chosen for their durability and resistance to corrosion, a testimony to the pump’s ability to withstand prolonged exposure to aggressive and abrasive substances. In practical application, users have reported significant gains in both productivity and equipment longevity. Through firsthand experience, operators note the exceptional ease of maintenance attributed to the balanced design, which prevents unnecessary wear and tear. This user feedback underlines the pump’s capability to maintain long-term performance with minimal intervention, a critical factor for industries operating 24/7 with little margin for error. In conclusion, the double volute centrifugal pump represents a substantial leap forward in pump technology. Its design not only resolves the limitations of single volute systems but also presents a robust solution aligned with modern industry demands. For businesses prioritizing efficiency, reliability, and low operational costs, investing in double volute centrifugal pumps is a strategic decision supported by engineering expertise, authoritative performance data, and user trust. As industries continue to evolve, the role of these pumps as essential components in fluid handling systems is set to expand, ensuring their relevance and indispensability in the years to come.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024