-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 13, 2025 00:18

Back to list

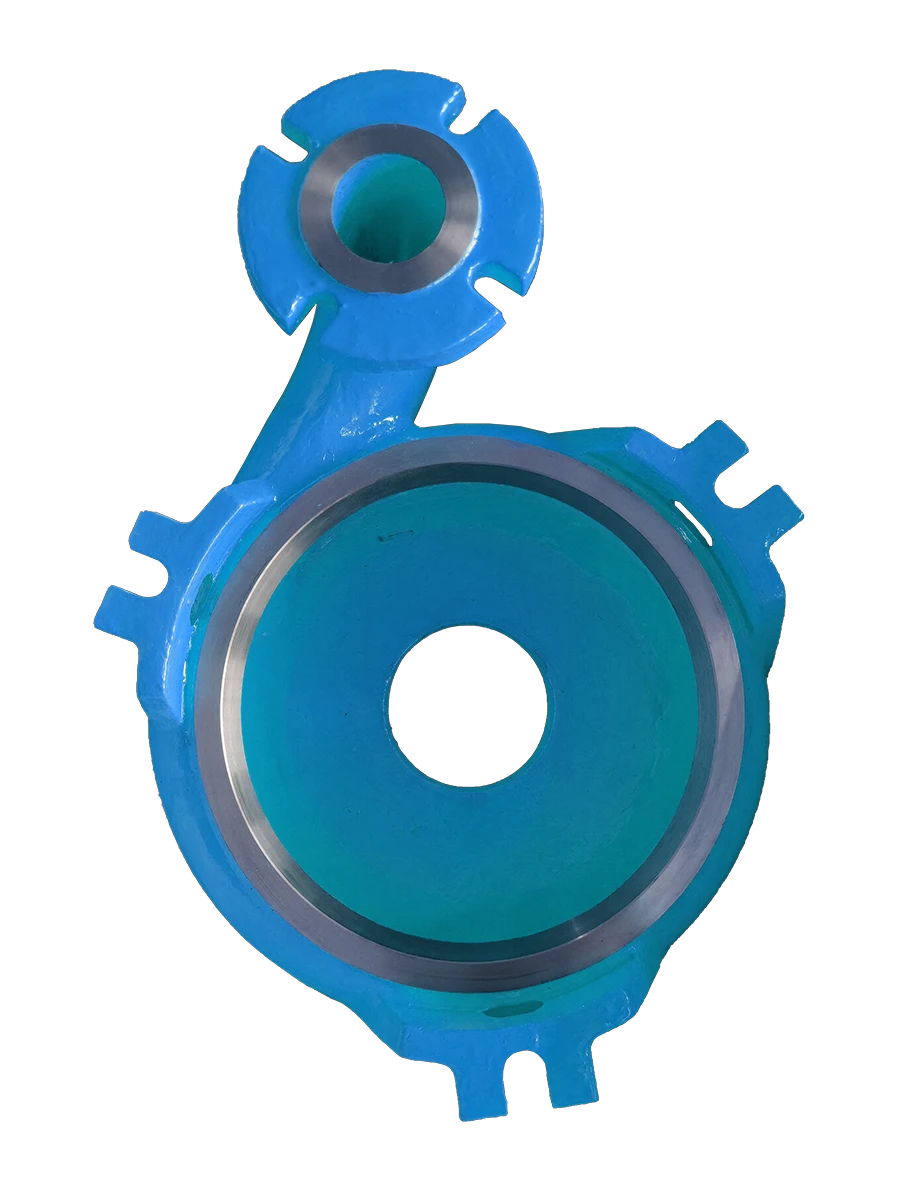

double impeller pump

Understanding Double Impeller Pumps A Comprehensive Guide

Authoritative Perspectives on Installation and Maintenance Proper installation and maintenance are crucial to the operational success of double impeller pumps. Authorities in pump technology recommend ensuring the alignment of the motor and pump components to minimize wear and vibration. Routine maintenance checks should include monitoring bearing condition, seal integrity, and impeller balance to prevent operational downtimes. As an authority in the field, I emphasize the importance of following manufacturer guidelines and leveraging authorized service centers for repairs to maintain warranty protections and safety standards. Building Trust Through Proven Performance Trust in double impeller pump technology is fortified through proven performance in demanding environments. Whether managing municipal water systems or supporting agricultural irrigation, these pumps demonstrate resilience and adaptability. Users consistently attest to their reliability under fluctuating demand and variable operating conditions. A testimony to their trustworthiness is their ubiquitous presence in critical infrastructure projects worldwide. Innovation Driving Future Developments The future of double impeller pumps looks promising with ongoing innovations aimed at improving energy efficiency and environmental sustainability. Cutting-edge research is exploring the integration of smart sensors and IoT technology to enable predictive maintenance, monitor real-time performance data, and optimize energy consumption. This progressive trajectory ensures that double impeller pumps remain at the forefront of fluid management solutions in a rapidly evolving technological landscape. Double impeller pumps are more than mere components in fluid systems; they embody engineering excellence, efficiency, and reliability. By understanding their design intricacies, material considerations, and best practices for maintenance and operation, industries can harness their power to achieve unparalleled performance. This knowledge positions professionals, facility managers, and engineers to make informed decisions, ensuring long-term benefits and sustained operational success.

Authoritative Perspectives on Installation and Maintenance Proper installation and maintenance are crucial to the operational success of double impeller pumps. Authorities in pump technology recommend ensuring the alignment of the motor and pump components to minimize wear and vibration. Routine maintenance checks should include monitoring bearing condition, seal integrity, and impeller balance to prevent operational downtimes. As an authority in the field, I emphasize the importance of following manufacturer guidelines and leveraging authorized service centers for repairs to maintain warranty protections and safety standards. Building Trust Through Proven Performance Trust in double impeller pump technology is fortified through proven performance in demanding environments. Whether managing municipal water systems or supporting agricultural irrigation, these pumps demonstrate resilience and adaptability. Users consistently attest to their reliability under fluctuating demand and variable operating conditions. A testimony to their trustworthiness is their ubiquitous presence in critical infrastructure projects worldwide. Innovation Driving Future Developments The future of double impeller pumps looks promising with ongoing innovations aimed at improving energy efficiency and environmental sustainability. Cutting-edge research is exploring the integration of smart sensors and IoT technology to enable predictive maintenance, monitor real-time performance data, and optimize energy consumption. This progressive trajectory ensures that double impeller pumps remain at the forefront of fluid management solutions in a rapidly evolving technological landscape. Double impeller pumps are more than mere components in fluid systems; they embody engineering excellence, efficiency, and reliability. By understanding their design intricacies, material considerations, and best practices for maintenance and operation, industries can harness their power to achieve unparalleled performance. This knowledge positions professionals, facility managers, and engineers to make informed decisions, ensuring long-term benefits and sustained operational success.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024