-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 19, 2025 02:19

Back to list

dirty water slurry pump

Choosing the right dirty water slurry pump is crucial for industries that handle liquids mixed with abrasive solids, such as mining or construction. Understanding the intricacies of these pumps not only ensures operational efficiency but also extends the longevity of the equipment. Here’s a comprehensive guide to dirty water slurry pumps based on extensive experience and specialized knowledge in the field.

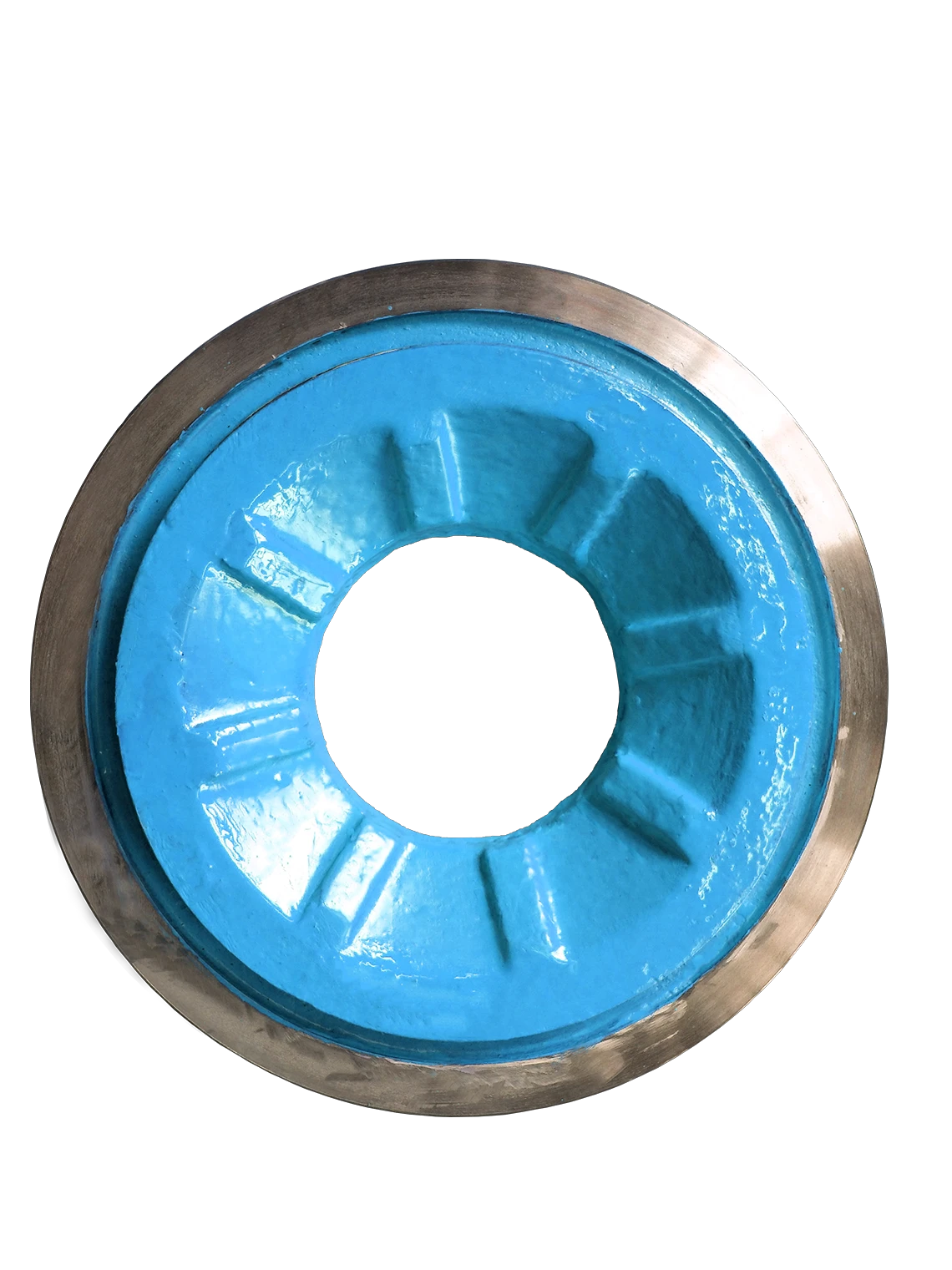

Trustworthiness in product choice often depends on the reliability of performance over long periods. Field studies and testimonials underscore the importance of regular maintenance schedules. Scheduled inspections and timely replacements of parts that commonly wear, such as the impeller and casing, can prevent unexpected failures. Training personnel in the maintenance of these pumps is equally crucial to ensure proper handling and extend the life of the equipment. Additionally, expert consultation with slurry pump specialists can provide tailored solutions that factor in the unique demands of the application. Some operations may benefit from custom-engineered pump systems that address unique challenges presented by particularly abrasive or corrosive slurries. Furthermore, technological advancements have introduced monitoring systems that track pump performance in real-time, highlighting any anomalies in operation. Utilizing IoT and AI technologies, these systems can predict maintenance needs and prevent costly downtimes by alerting operators before a failure occurs. In conclusion, the expertise in selecting and maintaining a dirty water slurry pump is instrumental to the smooth operation of industries reliant on fluid transport systems. The convergence of material science, engineering proficiency, and technological innovation creates pumps that not only meet but exceed operational expectations. Establishing a relationship with trusted suppliers and experts ensures continued support and adaptability to future challenges. The ultimate goal remains to achieve a balance of performance, durability, and cost-effectiveness, guaranteeing that your slurry pump investment is safeguarded and optimized.

Trustworthiness in product choice often depends on the reliability of performance over long periods. Field studies and testimonials underscore the importance of regular maintenance schedules. Scheduled inspections and timely replacements of parts that commonly wear, such as the impeller and casing, can prevent unexpected failures. Training personnel in the maintenance of these pumps is equally crucial to ensure proper handling and extend the life of the equipment. Additionally, expert consultation with slurry pump specialists can provide tailored solutions that factor in the unique demands of the application. Some operations may benefit from custom-engineered pump systems that address unique challenges presented by particularly abrasive or corrosive slurries. Furthermore, technological advancements have introduced monitoring systems that track pump performance in real-time, highlighting any anomalies in operation. Utilizing IoT and AI technologies, these systems can predict maintenance needs and prevent costly downtimes by alerting operators before a failure occurs. In conclusion, the expertise in selecting and maintaining a dirty water slurry pump is instrumental to the smooth operation of industries reliant on fluid transport systems. The convergence of material science, engineering proficiency, and technological innovation creates pumps that not only meet but exceed operational expectations. Establishing a relationship with trusted suppliers and experts ensures continued support and adaptability to future challenges. The ultimate goal remains to achieve a balance of performance, durability, and cost-effectiveness, guaranteeing that your slurry pump investment is safeguarded and optimized.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024