-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 11, 2025 09:44

Back to list

different types of impellers in centrifugal pumps

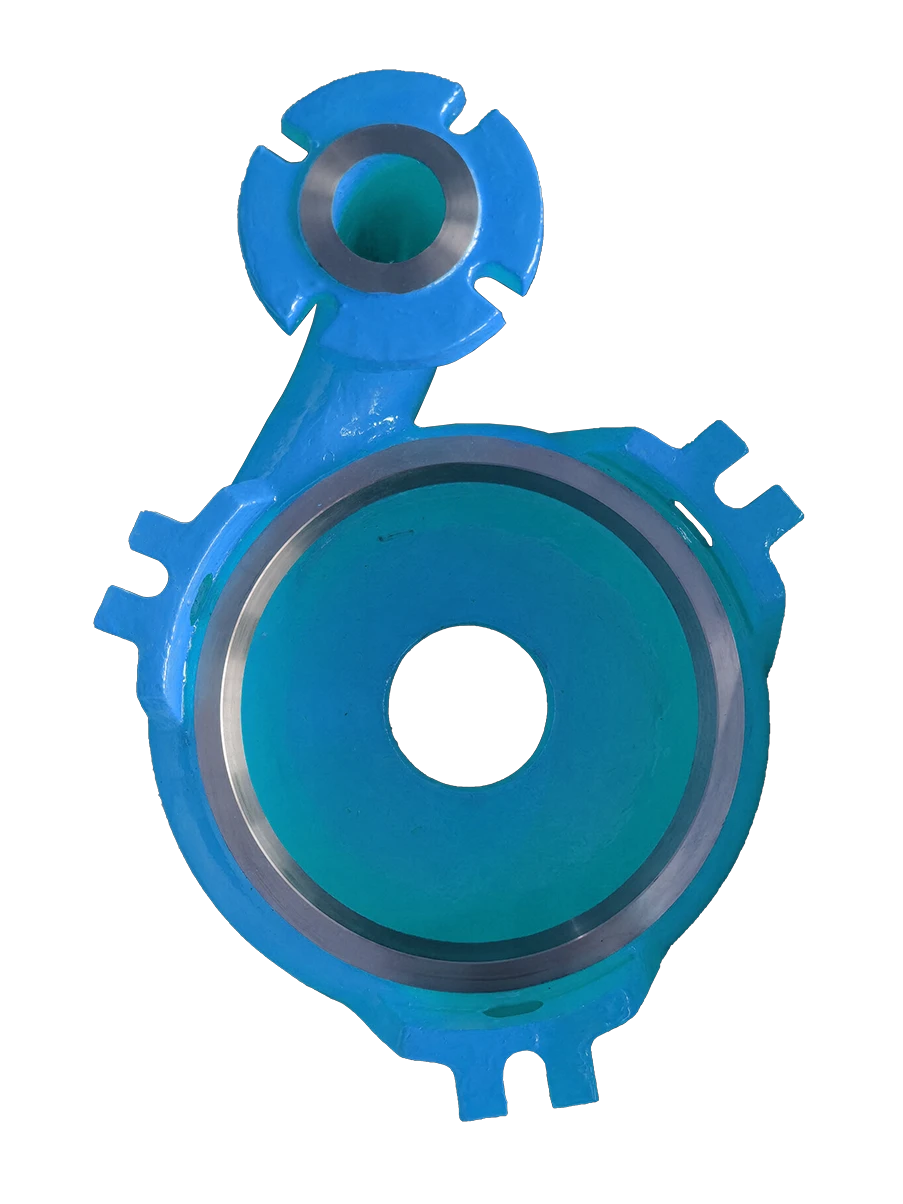

In the realm of centrifugal pumps, the impeller plays a pivotal role, acting as the heart of the pump by transferring energy from the motor to the fluid. Understanding the different types of impellers used in centrifugal pumps is crucial for engineers, industry professionals, and consumers alike, as the selection can significantly impact the pump’s efficiency, application suitability, and lifespan.

The emergence of Channel Impellers, sometimes referred to as single-channel or multi-channel designs, addresses the need for handling long-fibered materials and large solids without blocking. Their design permits the fluid to flow in straight pathways, reducing the chances of entanglements. Channel impellers find their niche in sewage treatment facilities and industrial plants dealing with fibrous sludges. Selecting the appropriate impeller hinges on factors such as the nature of the fluid being pumped, presence of solids, desired efficiency, and specific industry requirements. Trustworthy manufacturers provide detailed guidance and support, often customizing impeller designs to align with specific user requirements, ensuring optimal pump performance and durability. Finally, advancements in materials and engineering have introduced Corrosion-Resistant Impellers, crucial for industries working with aggressive chemicals. Utilizing materials like stainless steel, plastic composites, or titanium, these impellers retain their structural integrity and operational efficiency even under corrosive conditions. Professionals in chemical processing and maritime sectors vouch for these advancements, as they drastically reduce maintenance costs and extend pump life. Understanding these impeller types elevates one’s ability to make informed decisions when selecting centrifugal pumps, ensuring that the chosen design aligns ideally with the intended application. Whether for industrial giants or niche sectors, mastering impeller choices is a decisive step towards achieving operational excellence and sustainability.

The emergence of Channel Impellers, sometimes referred to as single-channel or multi-channel designs, addresses the need for handling long-fibered materials and large solids without blocking. Their design permits the fluid to flow in straight pathways, reducing the chances of entanglements. Channel impellers find their niche in sewage treatment facilities and industrial plants dealing with fibrous sludges. Selecting the appropriate impeller hinges on factors such as the nature of the fluid being pumped, presence of solids, desired efficiency, and specific industry requirements. Trustworthy manufacturers provide detailed guidance and support, often customizing impeller designs to align with specific user requirements, ensuring optimal pump performance and durability. Finally, advancements in materials and engineering have introduced Corrosion-Resistant Impellers, crucial for industries working with aggressive chemicals. Utilizing materials like stainless steel, plastic composites, or titanium, these impellers retain their structural integrity and operational efficiency even under corrosive conditions. Professionals in chemical processing and maritime sectors vouch for these advancements, as they drastically reduce maintenance costs and extend pump life. Understanding these impeller types elevates one’s ability to make informed decisions when selecting centrifugal pumps, ensuring that the chosen design aligns ideally with the intended application. Whether for industrial giants or niche sectors, mastering impeller choices is a decisive step towards achieving operational excellence and sustainability.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024