-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 20, 2025 07:47

Back to list

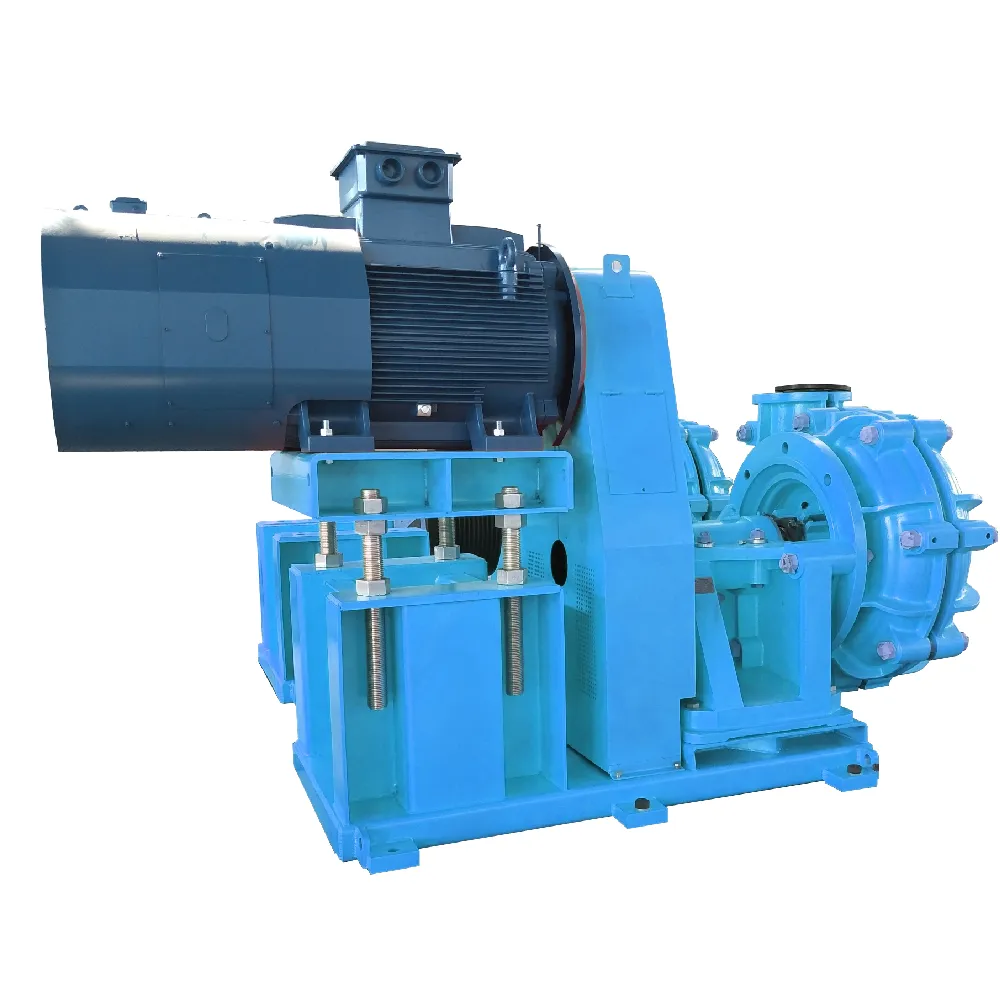

diaphragm pump for slurry

In the realm of industrial operations, efficiency and reliability are key. One crucial component that plays an integral role in processes dealing with abrasive and viscous materials is the diaphragm pump for slurry. Highly valued for their robustness and versatility, these pumps ensure smooth operation across various sectors, including mining, construction, and waste management.

The user experience with diaphragm slurry pumps also extends to their adaptability. They can be operational in various positions, and their compact size allows them to fit into tight spaces where larger pump systems might be impractical. Additionally, these pumps can be customized with different materials such as Teflon or rubber diaphragms, depending on the chemical nature of the slurry. This adaptability makes diaphragm pumps a universally applicable solution across numerous industrial and manufacturing landscapes. For those concerned about sustainability and environmental impact, diaphragm pumps also offer an eco-friendly solution. Their design minimizes leaks and emissions, thereby adhering to stringent environmental regulations. This aligns with the growing trend of industries striving to reduce their ecological footprint, providing an added advantage to using diaphragm pumps for slurry applications. In terms of trustworthiness and industry reliability, diaphragm slurry pumps have built a strong reputation over decades. Many leading manufacturers are continually innovating and testing their product lines, ensuring they meet both current industry standards and customer expectations. Prospective buyers can confidently rely on decades of field-tested engineering and customer feedback that drive ongoing improvements in pump design and functionality. In conclusion, diaphragm pumps for slurry represent a pinnacle of practical engineering solutions. Their combination of durability, reliability, and adaptability positions them as an essential tool in any industry dealing with challenging materials. With low maintenance requirements, robust performance under pressure, and environmentally friendly operation, these pumps stand out as a trustworthy choice, reinforcing their stature as a cornerstone in efficient industrial material handling.

The user experience with diaphragm slurry pumps also extends to their adaptability. They can be operational in various positions, and their compact size allows them to fit into tight spaces where larger pump systems might be impractical. Additionally, these pumps can be customized with different materials such as Teflon or rubber diaphragms, depending on the chemical nature of the slurry. This adaptability makes diaphragm pumps a universally applicable solution across numerous industrial and manufacturing landscapes. For those concerned about sustainability and environmental impact, diaphragm pumps also offer an eco-friendly solution. Their design minimizes leaks and emissions, thereby adhering to stringent environmental regulations. This aligns with the growing trend of industries striving to reduce their ecological footprint, providing an added advantage to using diaphragm pumps for slurry applications. In terms of trustworthiness and industry reliability, diaphragm slurry pumps have built a strong reputation over decades. Many leading manufacturers are continually innovating and testing their product lines, ensuring they meet both current industry standards and customer expectations. Prospective buyers can confidently rely on decades of field-tested engineering and customer feedback that drive ongoing improvements in pump design and functionality. In conclusion, diaphragm pumps for slurry represent a pinnacle of practical engineering solutions. Their combination of durability, reliability, and adaptability positions them as an essential tool in any industry dealing with challenging materials. With low maintenance requirements, robust performance under pressure, and environmentally friendly operation, these pumps stand out as a trustworthy choice, reinforcing their stature as a cornerstone in efficient industrial material handling.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024