-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 04, 2025 01:45

Back to list

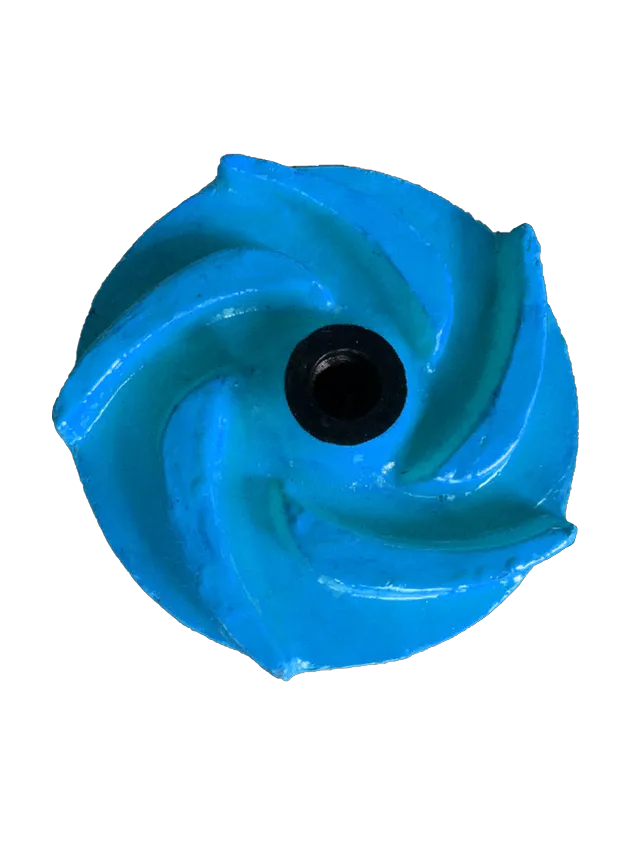

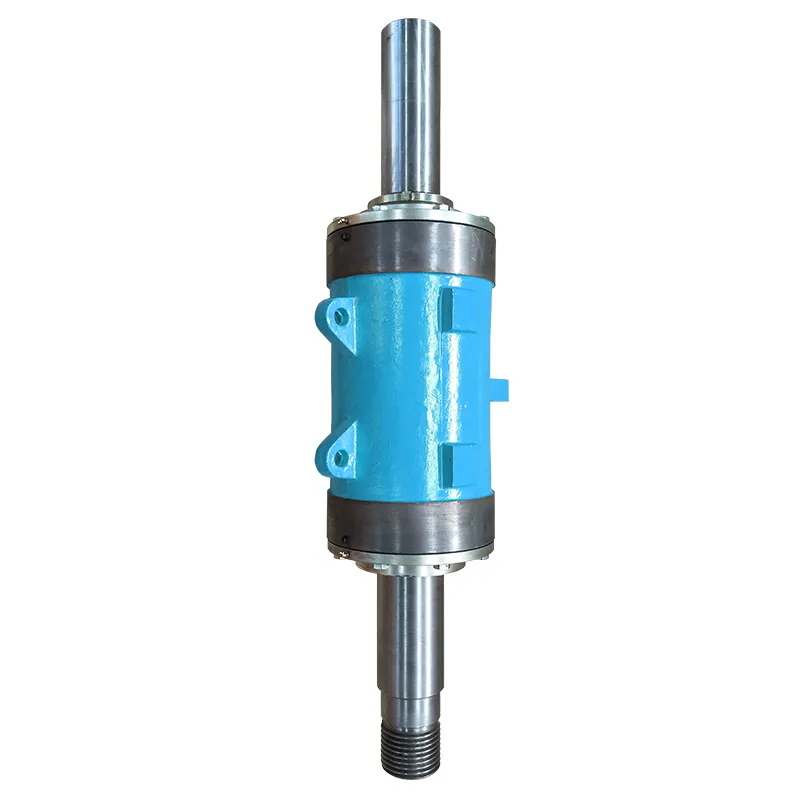

chrome hard metal slurry pump

In the ever-evolving world of industrial engineering, the chrome hard metal slurry pump is a beacon of both innovation and durability. These pumps are integral to a variety of heavy-duty industries, including mining, construction, and chemical processing, due to their unparalleled ability to handle abrasive and corrosive materials. Expertly designed to withstand the harshest conditions, chrome hard metal slurry pumps are indispensable for anyone requiring reliable performance and longevity in their operations.

Authoritativeness in the manufacture and deployment of chrome hard metal slurry pumps is crucial. Leading manufacturers often have decades of specialized experience, offering not just products but solutions tailored to the unique needs of their clients. They provide comprehensive support, from aiding in the selection of the appropriate pump model to offering insights on installation and operation to optimize performance. This level of service is invaluable, as a poorly selected pump can lead to inefficiencies and increased operational costs. Choosing the right chrome hard metal slurry pump also involves considering the specific slurry characteristics such as solid concentration, particle size, and acidity or alkalinity of the liquid. Real-world case studies demonstrate the trustworthiness and reliability of these pumps. One notable example comes from a gold mining operation where the deployment of chrome hard metal slurry pumps resulted in a 40% increase in throughput and a significant reduction in pump maintenance costs over a five-year period. In conclusion, the implementation of chrome hard metal slurry pumps stands as a pivotal decision for industries dealing with abrasive and corrosive slurries. Through the blend of experience, specialized knowledge, authoritative guidance, and reliable performance data, these pumps prove to be invaluable assets. They do not merely function as components of a system; they redefine the capability and efficiency of processing operations, providing long-term value and peace of mind. As such, they embody the pinnacle of engineering excellence, designed to meet the rigorous demands of industry while ensuring operational continuity and cost-effectiveness.

Authoritativeness in the manufacture and deployment of chrome hard metal slurry pumps is crucial. Leading manufacturers often have decades of specialized experience, offering not just products but solutions tailored to the unique needs of their clients. They provide comprehensive support, from aiding in the selection of the appropriate pump model to offering insights on installation and operation to optimize performance. This level of service is invaluable, as a poorly selected pump can lead to inefficiencies and increased operational costs. Choosing the right chrome hard metal slurry pump also involves considering the specific slurry characteristics such as solid concentration, particle size, and acidity or alkalinity of the liquid. Real-world case studies demonstrate the trustworthiness and reliability of these pumps. One notable example comes from a gold mining operation where the deployment of chrome hard metal slurry pumps resulted in a 40% increase in throughput and a significant reduction in pump maintenance costs over a five-year period. In conclusion, the implementation of chrome hard metal slurry pumps stands as a pivotal decision for industries dealing with abrasive and corrosive slurries. Through the blend of experience, specialized knowledge, authoritative guidance, and reliable performance data, these pumps prove to be invaluable assets. They do not merely function as components of a system; they redefine the capability and efficiency of processing operations, providing long-term value and peace of mind. As such, they embody the pinnacle of engineering excellence, designed to meet the rigorous demands of industry while ensuring operational continuity and cost-effectiveness.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024